Machines

MEGA CO2

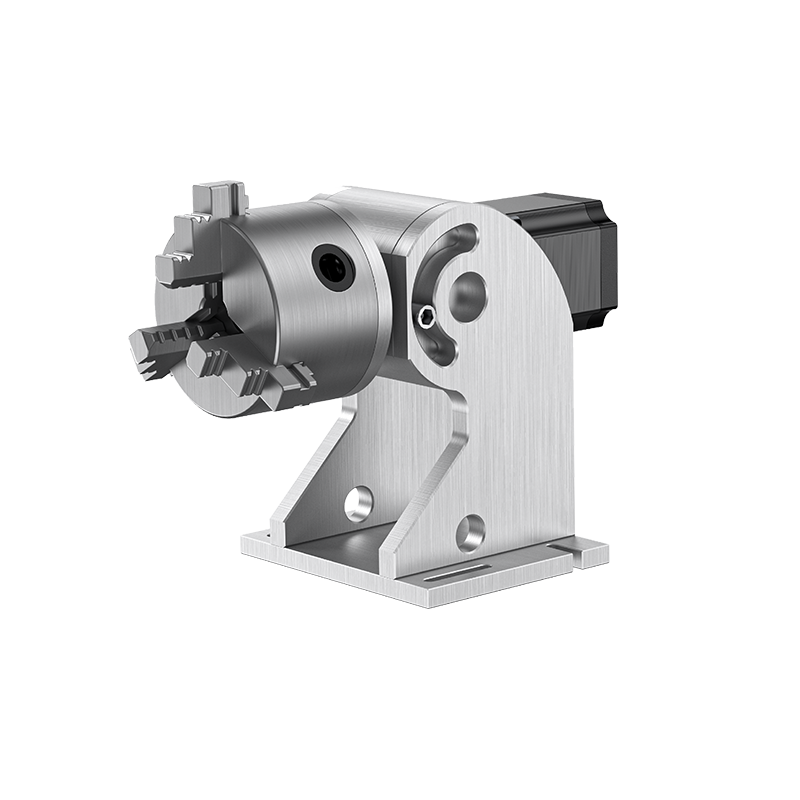

GA Series

Fastest Autofocus MOPA Fiber Laser for Metal Color Marking

GPro Series

High-End Split MOPA Fiber Laser for Metal Color Marking

GQ Series

Entry-Level Galvo-Tech Fiber Laser for Metal Marking

GM Series

The Galvo Mini offers powerful and precise marking capabilities with unbeatable value

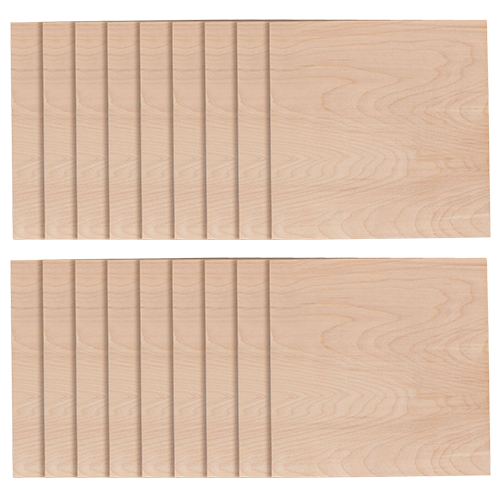

Desktop

The Monport Desktop Laser Cutter offers exceptional performance and safety, making it perfect for both hobbyists and commercial use.

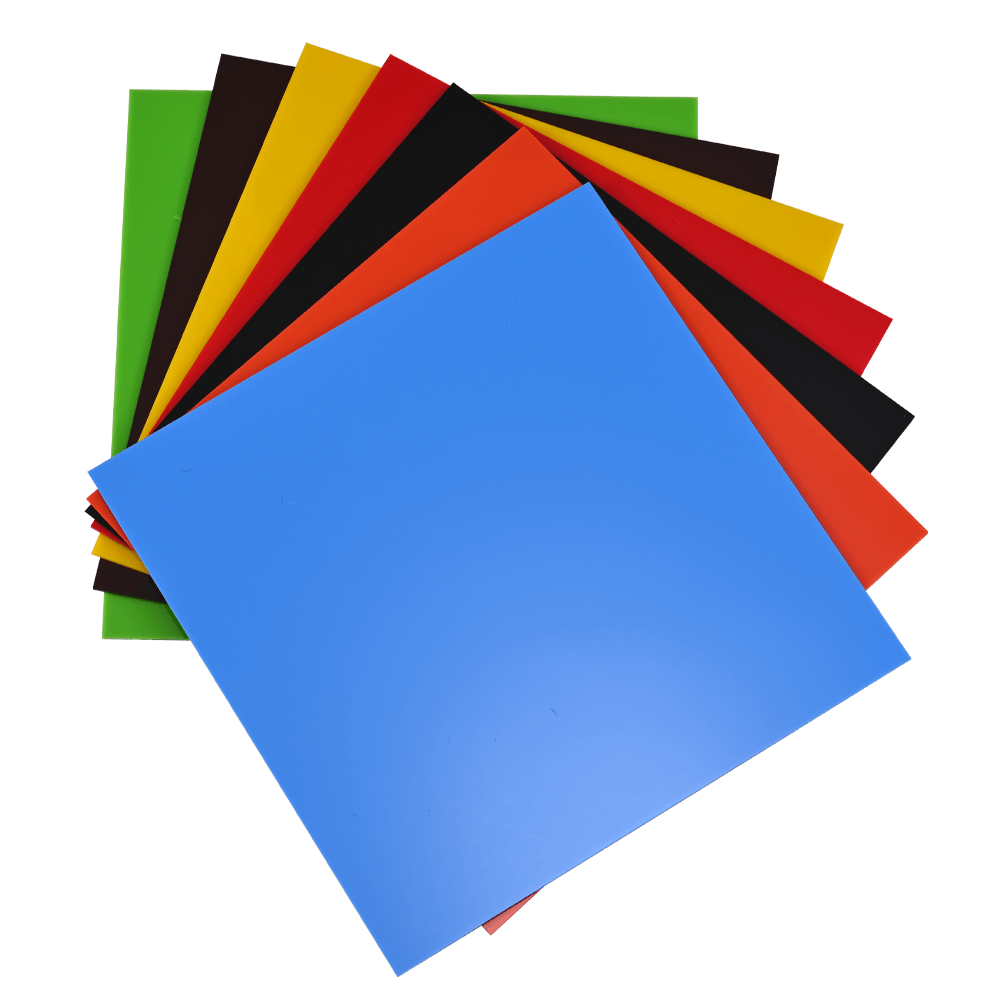

Industrial

The Monport 60W-150W CO2 laser engraver ensures safe, precise, and high-quality engraving for almost all levels of projects.

High Speed

The world's fastest CO2 engraver for glass tubes