Laser engraving with an 80 Watt laser is a versatile technique that can be used to create high-quality rubber stamps. With an 80 Watt laser, you can engrave intricate designs and text onto rubber stamps with precision and durability. In this guide, we'll explore the process of laser engraving rubber stamps, the benefits of using an 80W CO2 laser, and some tips for rubber stamp makers. Laser engraver files can play a crucial role in streamlining this process by offering pre-designed templates or layouts for engraving.

Monport 80W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus and Bracket

Don’t miss out – upgrade your engraving game now with black laser marking spray. Click here to order and use code BESTMP10 at checkout for the best deal!

Understanding 80W CO2 Lasers

An 80W CO2 laser is a powerful tool that is capable of engraving on a wide range of materials, including rubber. These lasers offer several advantages for rubber stamp engraving, especially when combined with laser engraver files:

- High Power Output: The 80W power output allows for deep and precise engravings, even on thicker rubber stamps. Using laser engraver files ensures accuracy in the designs.

- Versatility: CO2 lasers can engrave on a variety of materials, making them suitable for creating custom stamps for different applications. Pre-designed laser engraver files enhance this versatility.

- Precision: CO2 lasers offer high precision, ensuring that your engraved designs are sharp and detailed, especially when derived from laser engraver files.

- Speed: 80W CO2 lasers can engrave quickly, allowing you to efficiently produce large quantities of stamps. With the help of laser engraver files, production becomes even more efficient.

The Process of Laser Engraving Rubber Stamps

- Design Creation: Create your desired stamp design using design software or choose from pre-existing laser engraver files. Consider the size, complexity, and font style of the design.

- Rubber Stamp Preparation: Prepare the rubber stamp blank by cleaning it and ensuring it is free of any debris.

- Laser Engraving: Place the rubber stamp in the laser machine and start the engraving process using your selected laser engraver files. The laser will etch the design onto the rubber.

- Finishing: After engraving, you may need to clean or polish the stamp to remove any excess material or debris.

Simple Design Ideas for Rubber Stamps

Here are some simple design ideas for rubber stamps that you can create using a laser engraver:

Basic Text Stamps:

- Name Stamps: Create personalized name stamps for use in offices, schools, or at home.

- Date Stamps: Add a date stamp to documents or crafts.

- Company Stamps: Create custom stamps for businesses with company logos or contact information.

Monogram Stamps:

- Initials: Engrave your initials or the initials of others on stamps for personal or professional use.

- Custom Monograms: Design unique monograms that incorporate your name, initials, or other symbols.

Symbolic Stamps:

- Hearts: Create heart stamps for Valentine's Day or other special occasions.

- Stars: Use star stamps to add a decorative touch to projects.

- Animals: Engrave animal stamps for pet lovers or themed projects.

Custom Designs:

- Logos: Create custom stamps featuring your logo or brand identity.

- Quotes: Engrave inspirational quotes or sayings on stamps for personal or business use.

- Patterns: Experiment with different patterns and designs to create unique stamps.

Additional Tips:

- Keep it Simple: For small stamps, it's often best to keep the design simple and avoid overcrowding.

- Consider the Size: The size of the stamp will determine the amount of detail you can include in the design.

- Test Your Designs: Before engraving large quantities of stamps, test a few samples to ensure that the design is clear and legible.

By following these tips and exploring these design ideas, you can create unique and personalized rubber stamps that meet your specific needs.

Machine Guide Settings and Maintenance Tips

Machine Settings

- Power: Adjust the laser power based on the thickness of the rubber stamp and the desired depth of the engraving. A higher power setting may be required for thicker stamps or deeper engravings.

- Speed: The engraving speed will affect the quality and detail of the engraving. Experiment with different speeds to find the optimal setting for your specific project.

- Focus: Ensure that the laser beam is focused precisely on the surface of the rubber stamp. Adjust the focus height as needed.

- Air Assist: If your machine has air assist, adjust the air pressure to optimize the engraving process.

Maintenance Tips

-

Clean the Machine: Regularly clean the laser head, mirrors, and other components of the machine to prevent dust and debris from affecting performance.

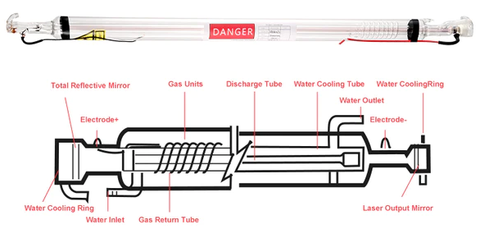

- Maintain the Laser Tube: Follow the manufacturer's recommendations for maintaining the laser tube. This may involve periodic cleaning or adjustments.

- Inspect the Optics: Regularly inspect the optics (mirrors and lenses) for damage or dirt. Clean them carefully if necessary.

- Lubricate Moving Parts: Lubricate any moving parts, such as the gantry and the Z-axis, according to the manufacturer's instructions.

- Check for Loose Connections: Ensure that all electrical connections are secure and tight.

Tips for Laser Engraving Rubber Stamps

- Choose the Right Rubber: Select a rubber material that is suitable for stamp making. Consider factors such as hardness, durability, and clarity.

- Optimize Laser Settings: Experiment with different laser settings, such as power, speed, and focus, to achieve the best results for your specific rubber material and design.

- Consider Air Assist: Using air assist can help to prevent charring and improve the quality of your engravings.

- Test Your Stamps: Before producing large quantities of stamps, test a few samples to ensure that the engraving is clear and legible.

FAQs

Q: Can I laser engrave on all types of rubber? A: While most types of rubber can be laser engraved, some materials may be more suitable than others. Experiment with different types of rubber to find the best one for your project.

Q: How do I prevent the rubber from charring during the engraving process? A: Using air assist, adjusting the laser power and speed, and ensuring proper ventilation can help to prevent charring.

Q: Can I engrave multiple designs on a single rubber stamp? A: Yes, you can engrave multiple designs on a single rubber stamp. However, the designs should be spaced apart to avoid overlapping.

Q: What is the maximum depth I can engrave on rubber? A: The maximum engraving depth will depend on the thickness of the rubber and the power of your laser machine. Generally, you can engrave up to 5-7mm deep on most rubber materials.

Q: Can I use a laser engraver to cut rubber stamps? A: While it is possible to cut rubber with a laser, it is generally not recommended as it can damage the cutting edge of the laser. For cutting rubber stamps, it is better to use a mechanical cutter.

Enhance Your Metal Engraving with Monport Black Laser Marking Spray

Monport black laser marking spray is designed to provide sharp, high-contrast markings on a variety of metals, including aluminum, brass, and stainless steel. When used with CO2 laser engraving machines, this black laser marking spray ensures a smooth, even application that delivers long-lasting, permanent marks. The quick-drying formula of this spray helps maintain a fast-paced workflow, allowing the markings to dry in just minutes. With its easy-to-use design, Monport black laser marking spray creates professional-grade results for any metal engraving project. Whether you’re customizing tools, jewelry, or industrial parts, this black laser marking spray will ensure your creations stand out with exceptional precision and clarity.

Conclusion

Laser engraving is a powerful technique for creating high-quality rubber stamps. By using an 80W CO2 laser and following the tips in this guide, you can produce custom stamps with precision and durability. Whether you're a hobbyist or a small business owner, laser engraving rubber stamps can be a rewarding and profitable venture.

Ready to start creating your own rubber stamps? Contact us today to learn more about our 80W CO2 laser engravers and get started on your next project.

Ready to bring your rubber stamp business to life? Grab your Monport 80W CO2 Laser Engraver now and use code BESTMP10 at checkout – Click here to shop today!