Importance of Regular Maintenance

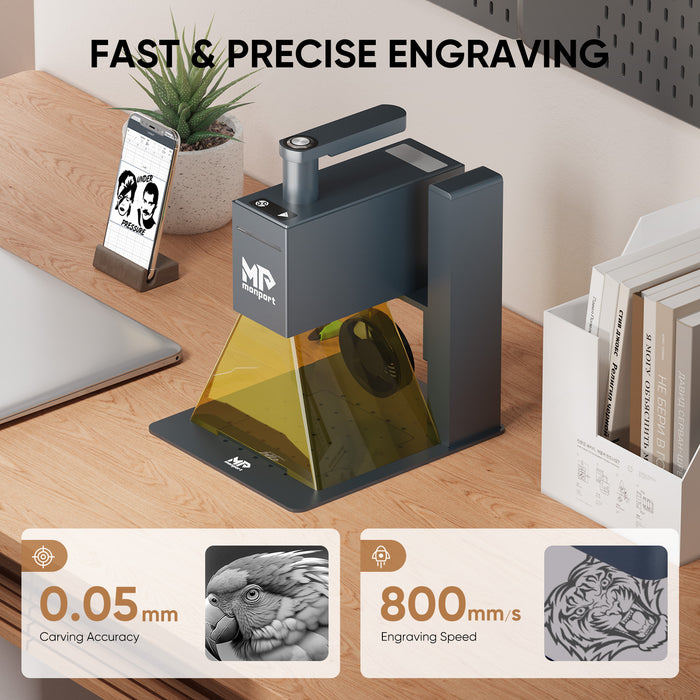

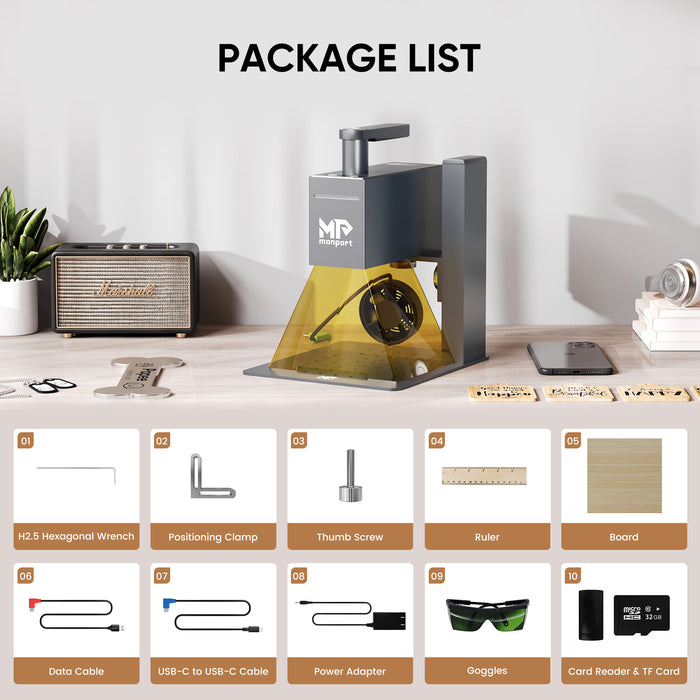

Regular maintenance of your Monport 6W handheld laser engraver and diode laser cutter and engraver with Auto Focus helps in preventing unexpected breakdowns and ensures that the machine functions at its best. By keeping your engraver clean and well-maintained, you can extend its lifespan and avoid costly repairs, and black laser marking spray can be used to improve the precision and clarity of your engravings.

Key Benefits of Regular Maintenance:

- Prolongs the machine’s lifespan

- Ensures consistent engraving quality

- Reduces the likelihood of mechanical failures

- Minimizes downtime and repair costs

Cleaning Your Diode Laser Engraver

Cleaning your diode laser cutter and engraver is one of the most crucial aspects of maintenance. Dust, debris, and residue from the materials you engrave can accumulate over time, affecting the machine’s performance.

Steps for Cleaning:

- Power Off the Machine: Always turn off and unplug your engraver before cleaning to avoid accidents.

- Clean the Work Area: Use a soft brush or cloth to remove any dust or debris from the engraving area.

- Wipe the Laser Lens: Use a microfiber cloth and a small amount of isopropyl alcohol to gently clean the laser lens. Avoid applying too much pressure to prevent damage.

- Check the Cooling Fans: Dust can accumulate in the cooling fans, reducing their efficiency. Use compressed air to blow out any dust from the fans.

- Clean the Exterior: Wipe down the exterior of the machine with a damp cloth to remove any dirt or fingerprints.

Materials Needed for Cleaning:

| Material | Purpose |

|---|---|

| Soft Brush/Cloth | Dust removal from the work area |

| Microfiber Cloth | Gentle cleaning of the laser lens |

| Isopropyl Alcohol | Cleaning agent for the laser lens |

| Compressed Air | Dust removal from cooling fans |

| Damp Cloth | Cleaning the machine’s exterior |

Inspecting the Components

Regular inspection of your Monport 6W Handheld Diode Laser Engraver with Auto Focus can help you identify potential issues before they become serious problems. Here’s what you should check, and black laser marking spray can also be applied to ensure clearer and more precise engravings.

- Laser Module: Ensure the laser module is securely attached and free from any damage.

- Belts and Rails: Inspect the belts and rails for signs of wear and tear. Replace any worn-out parts as needed.

- Cooling System: Check the cooling system to ensure it’s functioning properly. A faulty cooling system can lead to overheating and damage to the laser.

- Electrical Connections: Make sure all electrical connections are secure and there are no frayed wires.

Inspection Checklist:

- Laser module condition

- Belt and rail wear

- Cooling system functionality

- Electrical connection integrity

Lubrication and Calibration

Lubricating and calibrating your diode laser engraver will ensure smooth operation and accurate engraving.

Lubrication:

- Apply a small amount of lubricant to the rails and moving parts to reduce friction and wear.

- Use a lubricant that is suitable for precision machines.

Calibration:

- Calibrate the laser to ensure it is properly aligned. This is especially important if you notice a drop in engraving accuracy.

- Follow the manufacturer’s instructions for calibration to avoid damaging the machine.

Lubrication and Calibration Tips:

- Use only a recommended lubricant.

- Calibrate your machine at regular intervals or after any significant movement of the engraver.

Storing Your Diode Laser Engraver

Proper storage of your Monport 6W handheld laser engraver and diode laser cutter and engraver with Auto Focus is essential when it’s not in use. This helps prevent dust accumulation and potential damage to your diode laser cutter and engraver. Keeping it in a clean, dry, and safe environment will prolong its lifespan and ensure it’s ready for the next project, and black laser marking spray can be used to improve the clarity and quality of your engravings.

Storage Tips:

- Cover the Machine: Use a dust cover to protect the engraver from dirt and dust.

- Store in a Dry Place: Keep the engraver in a dry area to prevent moisture-related damage.

- Avoid Extreme Temperatures: Store the machine in a temperature-controlled environment to avoid damage from extreme heat or cold.

FAQs

Q1: How often should I clean my diode laser engraver?

- A1: You should clean your engraver after every use, or at least once a week, depending on how frequently you use it.

Q2: What should I do if I notice a drop in engraving quality?

- A2: First, clean the laser lens and inspect the machine for any issues like loose belts or worn-out components. If the problem persists, consider recalibrating the laser.

Q3: Can I use any lubricant on my diode laser engraver?

- A3: No, it’s important to use a lubricant that is specifically designed for precision machines. Check the manufacturer’s recommendations.

Q4: What is the best way to store my diode laser engraver?

- A4: Store the engraver in a dry, temperature-controlled environment and cover it with a dust cover when not in use.

Important Details

- Always unplug the machine before performing any maintenance.

- Use only recommended cleaning materials to avoid damaging sensitive parts.

- Regularly check for software updates that may improve the performance of your engraver.

- Keep a maintenance log to track when you last cleaned, lubricated, and calibrated the machine.

Takeaways

- Regular maintenance and cleaning are crucial for the optimal performance of your Monport 6W Handheld Diode Laser Engraver with Auto Focus.

- Simple tasks like cleaning the lens, inspecting components, and proper storage can significantly prolong the lifespan of your machine.

- Keep a close eye on the laser module, belts, and cooling system to ensure they are in good working order.

- Lubrication and calibration are essential for smooth operation and accurate results.

Conclusion

Maintaining and cleaning your Monport 6W handheld laser engraver and diode laser cutter and engraver with Auto Focus is an investment in the longevity and performance of your machine. By following the steps outlined in this guide, you can ensure that your engraver continues to operate at its best, providing you with consistent, high-quality results. Regular maintenance not only prevents costly repairs but also maximizes the efficiency and precision of your engraving projects. Keep your diode laser cutter and engraver in top condition, and it will serve you well for years to come, and black laser marking spray can further enhance the precision and depth of your engravings.

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!