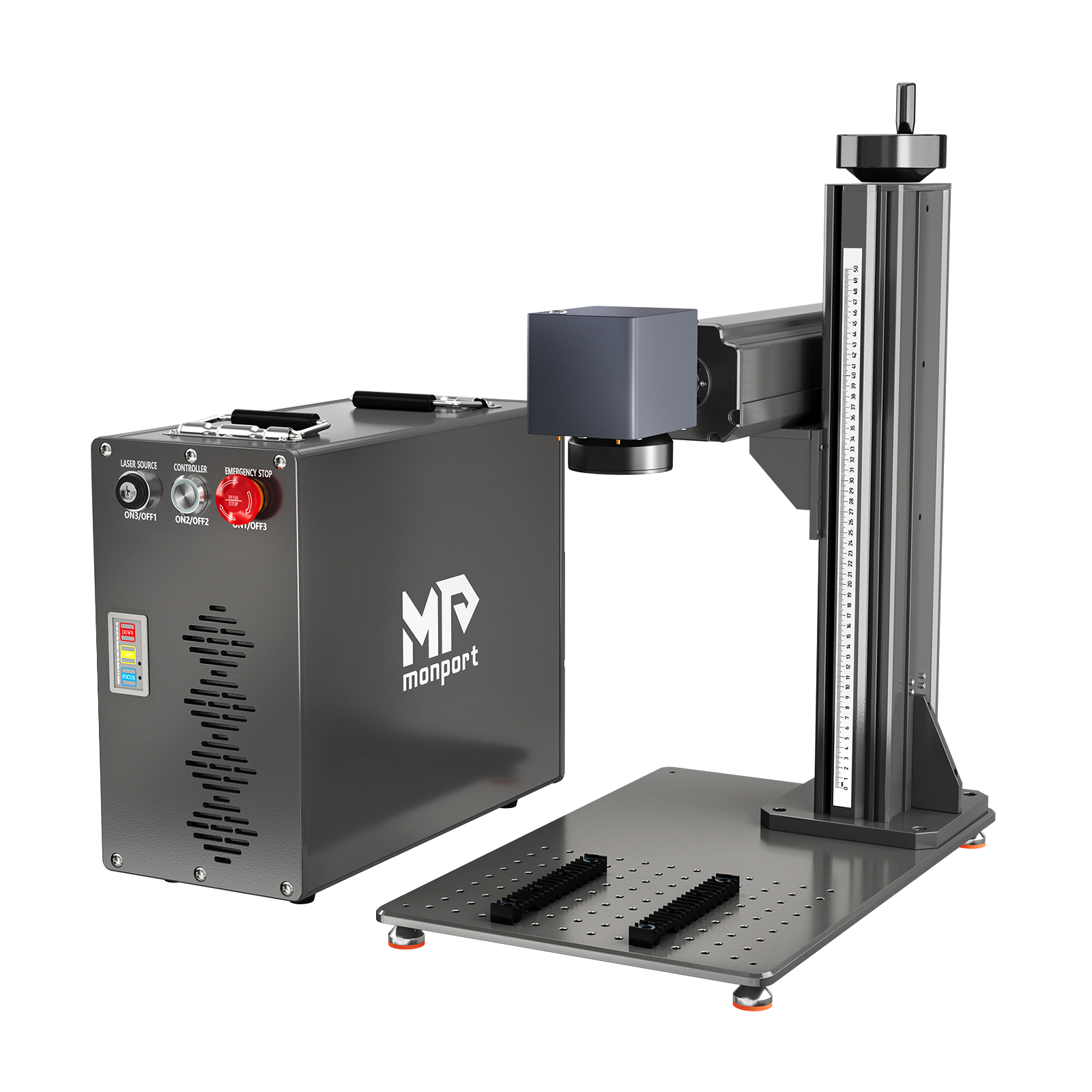

Monport GM 6W UV Laser Engraver & Marking Machine

Monport GM 10W UV Laser Engraver & Marking Machine

How do fiber and UV lasers differ?

How do fiber and UV lasers differ?

Fiber lasers work best on metals, producing durable, deep engravings, thanks to their 1064 nm wavelength. UV lasers have a shorter wavelength (355 nm), allowing precise, low-heat marking on sensitive materials like plastics, glass, and thin films.

What is a UV laser engraver used for?

What is a UV laser engraver used for?

A UV laser engraver delivers precise, high-detail markings on materials like plastics, glass, ceramics, and even metals. It’s perfect for logos, barcodes, QR codes, and serial numbers, especially on delicate surfaces, thanks to its low-heat process.

What does a UV laser marking machine do?

What does a UV laser marking machine do?

It produces precise, permanent marks on metals and non-metals without touching the surface. Common applications include medical devices, electronics, and security labels. The low-heat process ensures clean, detailed markings without damage.

Which materials can a UV laser engraver work on?

Which materials can a UV laser engraver work on?

UV lasers can mark and engrave plastics, glass, ceramics, metals, leather, and coated surfaces. Their low-heat process keeps markings sharp and prevents material damage.

How long does a UV laser last?

How long does a UV laser last?

A quality UV laser typically runs 10,000–20,000 hours, depending on power, cooling, and upkeep. Proper maintenance, like cleaning optics and ensuring good ventilation, keeps performance stable for many years, making it a durable, low-maintenance solution for precise marking.

Which is better — a 6W or 10W UV laser?

Which is better — a 6W or 10W UV laser?

A 10W UV laser works faster, with deeper and higher-contrast markings, making it ideal for production and industrial applications. A 6W UV laser is more compact and affordable, perfect for fine-detail work like jewelry or microelectronics. Choose 10W for speed and output, 6W for precision and cost-efficiency.

Can a UV laser engrave wood?

Can a UV laser engrave wood?

Yes, but it’s best for fine, high-contrast surface markings rather than cutting or deep engraving. Its 355 nm wavelength allows precise, low-heat detailing with minimal charring. For cutting or deeper work, a CO₂ laser is more suitable.

Can UV lasers cut metal?

Can UV lasers cut metal?

No. UV lasers are designed for precise marking and engraving, not cutting. They can etch serial numbers, barcodes, or logos on metals, but for cutting aluminum or stainless steel, a fiber laser or CO₂ laser with assist gas is needed.

Can a UV laser cut acrylic?

Can a UV laser cut acrylic?

UV lasers can mark and lightly engrave acrylic with high precision, creating smooth, frosted details without yellowing or burning. For cutting thicker sheets (3 mm+), a CO₂ laser is needed. UV lasers are best for fine surface patterns, text, or logos.

Looking for advanced marking technology that delivers flawless results without damaging delicate materials? A UV laser engraver is the ultimate solution for ultra-fine, high-precision applications. Designed for cold processing, a UV laser engraving machine minimizes thermal impact, making it perfect for sensitive materials like plastics, glass, and coated metals.

Unlike traditional laser systems, UV laser marking uses a shorter wavelength that reduces heat-affected zones. This ensures clean edges, sharp contrast, and permanent marks with zero burning or warping.

Precision UV Laser Marking Without Material Damage

A professional UV laser marking machine allows you to engrave serial numbers, QR codes, barcodes, logos, and intricate micro-patterns with exceptional clarity. Thanks to cold laser technology, the UV laser beam breaks molecular bonds instead of burning the surface — delivering smooth, precise, and damage-free results.

Whether you're working with:

Plastics and polymers

Glass and crystal

Ceramics

Coated or delicate metals

Electronic components

A UV laser engraving machine ensures maximum precision with minimal material stress.

Industrial Applications to Custom Artwork

From large-scale industrial production to personalized custom artwork, a UV laser engraver provides unmatched versatility. Manufacturers rely on UV laser marking machines for:

Medical device marking

Electronic component engraving

Cosmetic packaging coding

Food and pharmaceutical labeling

Micro-marking applications

Artists and creators also benefit from UV laser technology for detailed engraving on fragile surfaces that require absolute precision.

Why Choose a UV Laser Engraving Machine?

✔ Cold Laser Processing

UV laser technology prevents heat buildup, eliminating deformation, discoloration, and cracking.

✔ Exceptional Micro-Marking Precision

The fine beam quality of a UV laser enables intricate details and high-resolution engraving.

✔ Multi-Material Compatibility

A UV laser engraver works efficiently on glass, plastic, ceramics, silicon, and select metals.

✔ Permanent, High-Contrast Results

UV laser marking creates durable marks that resist fading, chemicals, and wear.

✔ High-Speed Production Efficiency

Modern UV laser marking machines are designed for fast cycle times and streamlined workflows.

Upgrade to Advanced UV Laser Technology

If precision, durability, and non-contact processing are critical for your business, investing in a UV laser engraving machine is the smart move. With superior beam control and cold marking capabilities, a UV laser delivers clean, professional results across industries.

Explore our top-rated UV laser engraver models today and discover how UV laser marking can transform your production efficiency and product quality.