In modern craftsmanship, laser engraving has emerged as a revolutionary technique, offering unparalleled precision and versatility. Among the options of materials that can be embellished with laser artistry, stainless steel stands out for its durability, sleekness, and timeless appeal. From personalized gifts to industrial applications, laser engrave steel opens up a world of possibilities for artists, engineers, and hobbyists alike. In this article, we delve into the intricate process of laser engraving stainless steel, exploring its techniques, applications, and the creative potential it unlocks.

A stainless steel laser engraver uses a high-powered laser beam to etch designs, patterns, or text onto the surface of a laser etching stainless steel piece. Unlike traditional engraving methods, which rely on physical contact, laser etching stainless steel achieves precision through focused heat, vaporizing the metal to create intricate designs with exceptional accuracy. For even greater contrast, black laser marking spray is often used to enhance visibility and depth.

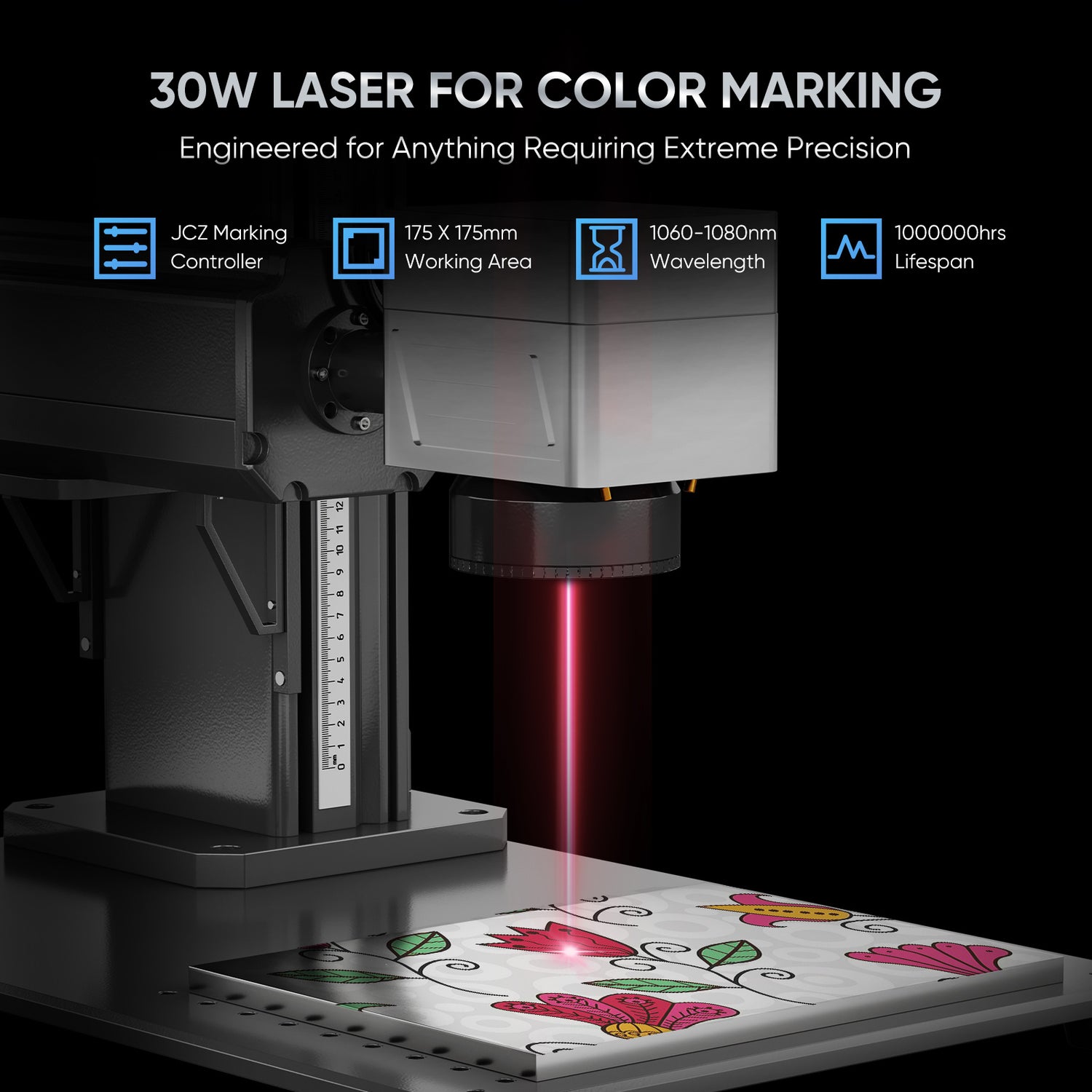

Monport GPro 30W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

Read More : The Benefits of Stainless Steel Laser Engraving

Key Techniques and Considerations for Laser Engraving on Stainless Steel

-

Laser Settings: Achieving optimal results with a stainless steel laser engraver requires precise control of laser power, speed, and frequency. Adjusting these parameters based on material thickness and design complexity ensures clean, crisp markings.

-

Surface Preparation: Always clean and polish the stainless steel surface before engraving. This ensures the laser etching stainless steel performs at its best without interference from dust or oil.

-

Masking: To prevent discoloration or thermal damage, apply laser marking spray or masking tape before engraving. This step is especially useful when using a high-powered stainless steel laser engraver.

-

Vector vs. Raster Engraving: Choose between vector engraving for sharp outlines or raster engraving for detailed fills. A reliable stainless steel laser engraver should allow seamless switching between both modes.

-

Post-Processing: After using the laser engrave steel, polish or clean the surface to enhance clarity and contrast of the design.

Applications of Laser Engraved Stainless Steel

- Personalized Gifts: Laser engraved stainless steel products, such as jewelry, keychains, or drinkware, offer a unique and meaningful way to commemorate special occasions or express personal sentiments.

- Industrial Marking: Stainless steel components used in industries such as automotive, aerospace, and electronics can be laser engraved with serial numbers, logos, or barcodes for identification and traceability purposes.

-

Branding and Promotion: Businesses can leverage laser etching stainless steel to create branded merchandise, promotional items, or corporate gifts that leave a lasting impression on customers and clients.

- Artistic Expression: Artists and designers explore the artistic potential of laser engrave steel to create intricate patterns, abstract designs, or textural effects that push the boundaries of traditional metalwork.

Whether you're just finding another hobby or an entrepreneur trying to venture in the laser engraving industry, Monport's laser engravers are just what you need! Take a look at their premium-quality fiber laser engraver:

Monport GPro 30W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

| Product | GPro 30 | ||||

| Picture |  |

||||

| Model | JL-F30W | ||||

| Rated Power | 30W | ||||

| Max. Marking Depth | 0.003in. | ||||

| on a Single Pass | (0.08mm) | ||||

| Beam Quality M2 | <1.35 | ||||

| Maximum Pulse Energy | 0.8 | ||||

| Required | Max. Humidity | <70% | |||

| Operating | |||||

| Environment | Temp. Range | 40–95°F(5–35°C) | |||

| Input Power | 110-120V 60Hz | ||||

| Expected Service Life | 100,000 hr. | ||||

| Central Wavelength | 1060-1080 nm | ||||

| Laser Frequency | 1-3000 kHz | ||||

| Pulse Width | 2-500 ns | ||||

| Beam Diameter | 7±1 mm | ||||

| Processing Area | 6.9×6.9 in.(175×175 mm) | ||||

| Max. Marking Speed | 393.7 ips(10000 mm/s) | ||||

| Min. Marking Depth | 0.0002 in.(0.005 mm) | ||||

| Min. Line Width | 0.006 in.(0.15 mm) | ||||

| Precision | ±0.1 µm | ||||

| Provided Operating Software | EZCad | ||||

Cutting-edge Laser Core & High-Performance Marking Control System

Monport introduces its 30W fiber laser marking machine, equipped with the advanced JCZ marking controller, ensuring robust performance and accuracy, freeing your creativity and processing capabilities from constraints.

Adaptable Laser Marking Functions

Our fiber laser engraving machine, featuring adjustable frequency (1-3000kHz) and pulse width (2-500ns), facilitates vivid stainless steel laser engraver markings, deep anodized aluminum engraving, precise cutting, drilling, and intricate designs on plastic buttons. Enjoy rich and accurate visual effects effortlessly.

Premium Quality Galvanometer

A superior fiber laser demands an exceptional galvanometer. Monport chooses the high-end Sino-Galvo SG7110 galvanometer for unparalleled stability, precise positioning, swift marking speed, and robust anti-interference capabilities. Its performance surpasses other brands by 100%.

Simple Focus with Accuracy

Our laser engraving machine incorporates three-point red light alignment for effortless focusing, accompanied by a red light preview for marking area visualization, facilitating precise marking position confirmation swiftly.

Enhanced Safety Measures

To ensure high levels of safety, we've implemented an access key to prevent unauthorized laser usage, along with a prominent E-stop button readily accessible for emergencies.

Flexible Operating Software

Monport's fiber laser marker is compatible with EzCad2, providing seamless operation across both Windows and Mac systems. Please note that LightBurn is exclusively available for use on Mac systems.

Frequently Asked Questions (FAQs)

1. Q: What makes laser engraving stainless steel better than traditional engraving methods?

A: Laser engraving offers exceptional precision and detail without physical contact, which means there’s no tool wear or surface damage. It also allows for faster production, cleaner results, and the ability to engrave intricate designs or fine text on stainless steel with consistent quality.

2. Q: Can I use the Monport GPro 30W Split MOPA Fiber Laser Engraver for materials other than stainless steel?

A: Yes, the Monport GPro 30W Split MOPA Fiber Laser Engraver is highly versatile. Besides stainless steel, it can engrave anodized aluminum, plastics, and coated metals. Its adjustable frequency and pulse width make it suitable for diverse engraving tasks, from marking barcodes to detailed artwork.

3. Q: How can I ensure the best results when laser engraving on stainless steel?

A: Always clean and polish the surface before engraving to remove dust or oil. Adjust the laser’s power, speed, and frequency according to the material thickness. Using black laser marking spray or masking tape can also improve contrast and protect against thermal discoloration.

Conclusion

Laser etching stainless steel represents a fusion of artistry and technology, offering limitless possibilities for creativity and innovation. Whether it's adding a personal touch to everyday objects or elevating the aesthetics of industrial components, the precision and versatility of laser engrave steel continue to inspire makers and creators worldwide, especially when paired with black laser marking spray for enhanced contrast. As this cutting-edge technique continues to evolve, its impact on the world of craftsmanship and design is bound to grow, unlocking new realms of possibility for those who dare to explore its depths. Visit Monport today for more machine guide blogs and to explore a vast selection of laser engravers for stainless steel.