Are you ready to take your leather crafting to the next level? Laser engraving offers a world of creative possibilities, allowing you to add intricate designs and personalization to your leather projects. In this article, we will guide you through the necessary steps and settings for leather laser engraving ideas. From understanding different leather types and their corresponding laser settings to exploring five inspiring leather engraving ideas, we hope to ignite your imagination and showcase the endless possibilities of leather laser engraving ideas.

Understanding Different Leather Types and Corresponding Laser Settings

Before diving into the exciting world of leather laser engraving ideas, it's essential to understand the characteristics of different leather types and how they respond to laser engraving. Here are a few popular leather types and their corresponding laser settings to achieve optimal results:

-

Full-Grain Leather: Known for its durability and natural beauty, full-grain leather engraves beautifully with laser technology. For full-grain leather, a power wattage of around 40-60W and an engraving speed of 200-400 mm/s are recommended on Monport's 80W CO2 Laser Engraver & Cutting Machine for crisp and precise engravings. This is a great material for leather laser engraving ideas.

-

Vegetable-Tanned Leather: Vegetable-tanned leather is a popular choice for traditional craftsmanship. It reacts well to laser engraving, allowing for intricate and detailed designs. Set the power to around 60-80W and engraving speed to 200-400 mm/s for optimal results. It's perfect for leather laser engraving ideas that involve detailed artistry.

-

Suede and Nubuck Leather: Suede and nubuck leather have a velvety texture, and laser engraving can add a unique touch to these materials. As the surface of these leathers can be more delicate, it's crucial to test engraving settings on a small area before proceeding. Start with lower power wattage (around 40-60W) and slower engraving speeds (100-200 mm/s) to avoid burning the material. These textures open up additional leather laser engraving ideas for subtle effects.

Remember, these settings serve as general guidelines, and it's essential to experiment and adjust them based on your specific leather and desired engraving effect. Tailoring these settings can help bring your leather laser engraving ideas to life.

Step-by-Step Guide to Laser Engraving on Leather

Now that we've explored the different leather types and laser settings, let's dive into the step-by-step process of laser engraving on leather:

Step 1: Preparation

Start by selecting a high-quality piece of leather and ensure it is clean and free from any dust or debris.

Step 2: Design and Software Setup

Create or import your desired design into laser engraving software such as RDWorks or LightBurn. Adjust the size, position, and other settings as needed.

Step 3: Machine Setup

Position the leather piece on the work bed of Monport's 80W CO2 Laser Engraver & Cutting Machine and secure it in place. Adjust the focal length according to the thickness of the leather to achieve the desired engraving depth.

Step 4: Test and Calibration

Perform a test run on a small area of the leather to ensure the settings are optimized for the desired effect. Make any necessary adjustments to power, engraving speed, or focal length based on the test results.

Step 5: Start Engraving

Begin the engraving process by starting the machine. Monitor the progress closely to ensure the engraving is going according to your expectations.

Step 6: Finishing Touches

Once the engraving is complete, remove the leather piece from the machine and gently clean off any residue. Apply leather conditioner or other finishing products to enhance the engraved design and protect the leather.

5 Creative Ideas for Laser Engraving on Leather

Personalized Wallets: Engrave initials, names, or meaningful quotes onto leather wallets for a personalized touch.

Level Up Your Leather Crafting Game

Whether you're creating wallets, bracelets, or journal covers, precision matters.

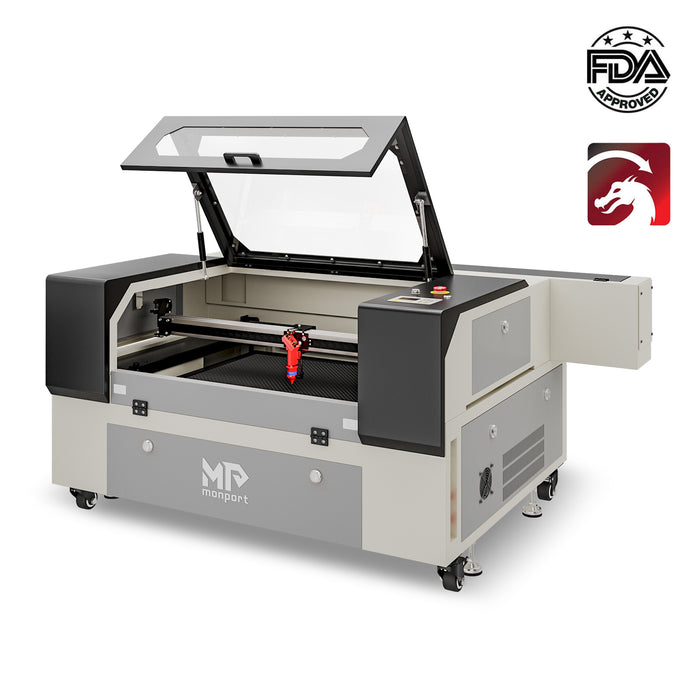

BESTMP10.Introducing Monport's 80W CO2 Laser Engraver & Cutting Machine

To unlock the full potential of your leather engraving projects, you need a reliable and high-performance laser engraver. Monport's 80W CO2 Laser Engraver & Cutting Machine is specifically designed to meet the demands of both enthusiasts and professionals. Its spacious work bed, precise control, and compatibility with popular software like RDWorks and LightBurn ensure impeccable engraving results.

The machine features a high-quality metal honeycomb board and aluminum panel, providing stability and double protection for your workpieces. With a power wattage of 80W and the ability to engrave at speeds up to 800mm/s, Monport's laser engraver empowers you to bring your leather engraving ideas to life.

Effortless Laser Marking with Monport Black Laser Marking Spray

Looking to elevate your laser engraving projects? Monport Black Laser Marking Spray is the solution you’ve been waiting for. This high-performance aerosol spray is designed for use with CO2 laser engraving machines, ensuring easy and precise results with every application. Whether you're personalizing jewelry, customizing glassware, or serializing tools, this spray provides you with high-contrast, permanent marks that stand out.

The Benefits of Using Black Laser Marking Spray

-

Compatible with CO2 Laser Engraving Machines Designed for use with CO2 laser engraving machines of 25 watts and above, Monport Black Laser Marking Spray is the ideal companion for your engraving needs. It transforms your metal surfaces into highly legible, permanent black marks after laser engraving, making it perfect for a wide range of applications from metalwork to custom art pieces.

-

Permanent, High-Contrast Marks When you apply Monport Black Laser Marking Spray, the result is a high-contrast, dark black mark on your metal surface that is permanent and durable. This spray works on various metals, including aluminum, stainless steel, and brass. The fine-grained formula ensures deep penetration into the metal, producing heat-resistant markings that will last for years, even under challenging conditions.

-

Even and Powerful Application With the advanced spray technology in Monport Black Laser Marking Spray, you can achieve a smooth, even application every time. The 14 oz can features an anti-clog nozzle that guarantees no blockages, making the spray process both easy and efficient. The nanoparticle formula delivers more coverage with a thinner coating, which results in a professional-quality finish for all your metal marking projects.

-

Easy to Use and Quick Drying Using Monport Black Laser Marking Spray couldn’t be simpler. Just shake the can for 2 minutes, spray from a distance of 6 to 8 inches, and let the surface dry for 5 minutes. Once it’s dry, you’re ready to engrave, saving you valuable time. After engraving, rinse and wipe away the residue to reveal your crisp, dark black markings without any fuss.

-

Effortless Cleanup and Maintenance After marking your metal pieces, simply rinse and wipe the surface to reveal your high-contrast engraving. The black laser marking spray ensures there is no residue left behind, so your workpieces remain clean and ready for immediate use. The easy cleanup means that you can maintain a smooth and efficient workflow, whether you’re working on a small DIY project or a larger-scale production.

Why Choose Monport Black Laser Marking Spray?

Monport’s Black Laser Marking Spray is a game-changer for anyone looking to create durable, precise, and high-quality laser marks on metal surfaces. Its compatibility with CO2 lasers, combined with its easy application and cleanup, makes it an indispensable tool for professionals and hobbyists alike. With Monport Black Laser Marking Spray, you can be confident that your metal engraving projects will have permanent, high-contrast results every time.

Add this versatile spray to your toolkit today and experience effortless laser marking like never before!

Conclusion

Leather laser engraving opens up a whole new world of creativity and personalization. With the right laser settings, a high-quality machine like Monport's 80W CO2 Laser Engraver & Cutting Machine, and a dash of imagination, you can transform your leather projects into unique and artistic masterpieces. Visit Monport's website today for the best deals on laser engraving machines and gain access to valuable tips to enhance your leather engraving skills.

Turn Your Leather Projects Into Masterpieces

Personalized, professional-quality leather engraving is just one step away.

Shop Monport’s 80W CO2 Laser Engraver now and save 10% with code BESTMP10.

Explore Deals & Craft Smarter

Read More: Creative Ideas for Laser Engraving Leather: A Guide for Makerspaces