Ⅰ. Laser engraver combining with leather industry

The laser engraving machine only needs to input the graphics and size to be cut into the computer, and the laser engraving machine will cut the entire material into the finished product you need according to the data on your computer. No tools or molds are needed. At the same time, it can save you a lot of investment in human resources. Therefore, laser engraving machines are also widely used in the leather industry.

The leather industry uses laser engraving machines to break the problems of slow speed of traditional manual and electric shears, difficulty in typesetting, low efficiency and serious waste of materials. The characteristics of fast speed and simple operation have brought great benefits to the development of the leather industry.

The application of laser engraving on leather is also called laser drilling, which is mainly used for shoe uppers, handbags, leather gloves, luggage and so on. The laser engraving machine has many advantages over traditional cutting methods: the edges of the leather cut by it are not yellowed, and the edges or curled automatically, no deformation, no hardening, consistent and accurate size; it can cut any complex shapes; high efficiency , Low-cost computer design graphics, can cut lace of any shape; processing does not have mechanical pressure on the work piece; safe operation, simple maintenance, etc. Due to the combination of laser and computer technology, users only need to design a pattern on the computer, and they can output and change the engraving pattern at any time, realizing the idea of designing and producing products. It can be said that the emergence of laser engraving machines has greatly promoted the development of the leather industry.

Ⅱ. How to engrave leather?

Laser engraving machine process requirements: the surface of the hook line will not be yellow, the background color of the material will be carved, the cutting edge of the leather will not be black, and the engraving must be clear. Laser engraving machine is suitable for engraving materials: synthetic leather, PU leather, PVC artificial leather, leather wool, semi-finished products, various leather fabrics, etc.

- Leather and style selection

First choose a piece of leather that appeals to you in color and texture. Of course, its size should match the size of the processing table of the CO2 laser engraving machine. The image size you choose should be the same as the wallet size to achieve the best results. Usually, customers like to design their own styles, such as names, wedding dates or some beautiful patterns. The actual engraving effect of the laser machine depends on the type of leather used and the response of the laser beam to the corresponding material.

There are several options in the four main types of leather, including dyed leather, vegetable tanned leather, and distressed textured leather:

- Full-grain leather-highest quality

- First layer of grain leather-the second highest quality

- Corrected grain leather (bottom leather/cut split leather)-also known as "real leather"

- Recycled leather-the lowest quality, made from leather scraps

Suede is another soft leather material. Although it is not as durable as the leather mentioned above, it can also be laser engraved and cut.

- Application of graphics software

Based on this, you should learn to use laser machine software to draw the design, and then print it on the wallet. This requires you to be proficient in operating the software and control system of the laser engraving machine.

After confirming the image, input it into the graphics software through the computer connected to the CO2 laser machine. Or, even if you are a beginner, you can directly design special images using software that is easy to learn and operate. At Monport laser, we provide free training for each customer to learn how to use the software and how to operate the entire laser processing.

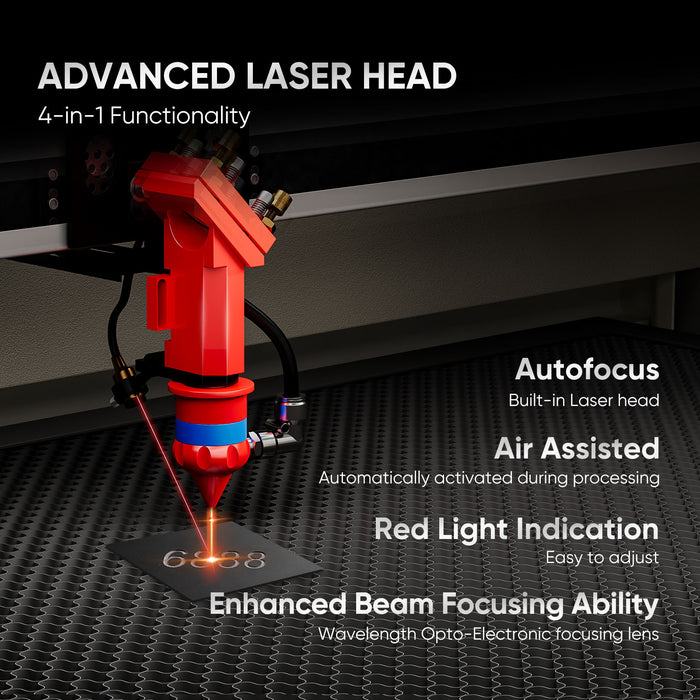

Laser engraving machine engraving speed: It depends on the size of the figure. The drawing speed of small patterns is relatively fast, the speed is 300~500mm/s, the engraving power is around 30~40%; The leather cutting is a little slower, the speed is 30mm/s, and the relative power is around 35-55%, and the general leather can be cut through.

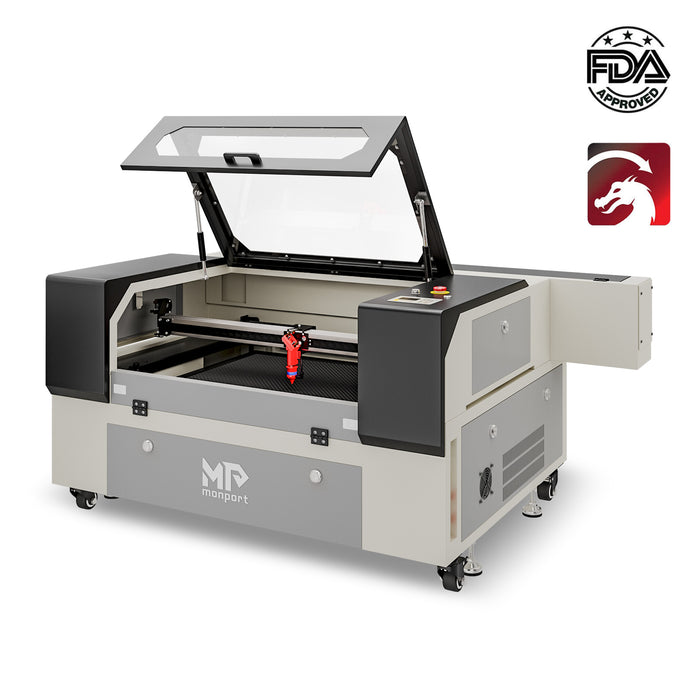

MACHINE: MONPORT 80W Co2 Laser Engraving & Cutting Machine

MATERIAL: One piece of recycled leather

PARAMETER SETTINGS:

- Cutting speed: 30mm/s

- Cutting power: 35%—55%

- Clean and fast engraving

Since there is an exhaust fan to remove dust to the outside, the entire engraving process will be clean and tidy. The smoke generated by the laser engraving work will be exhausted through the exhaust fan and will not affect the environment of your workshop. Similarly, you don't need to spend too much time waiting for the engraving result, you can complete the work in just a few minutes.

Ⅲ. Applications of laser cutting & engraving leather

Laser engraved leather wallet is a popular laser engraved craft. If you want to start a laser engraving business, you can engrave or create many types of materials and products with a laser cutting machine. The earlier you invest, the better.

- Leather patches

- Crafts

- Clothing

- Bracelets

- Belts

- Shoes

- Purses

- Wallets

- Briefcases

- Fashion Accessories

- Office products

Ⅳ. Final thoughts

It's surprising to see many new technologies are revolutionizing old-fashioned crafts like leather carving. Laser engraving not only demonstrates a new way of doing things, it also eliminates the old problems associated with the use of hand tools, which are error-prone, damage leather parts, and have limited types of designs that can be recreated.

Whether you want to produce a large number of leather products or just a one-time design, laser engraving can provide a more reliable and faster alternative than traditional leather engraving methods. If you are in the leather manufacturing industrial, laser engraving machine is actually an effective way to stay competitive.