Ⅰ.Rubber-All you need to know

Rubber is a versatile material, which can be used in a variety of domestic and industrial fields. From natural rubber derived from rubber tree to various synthetic rubber, rubber materials can be suitable for various occasions. Industrial chiller systems often rely on rubber components for insulation and durability.

Basic properties of rubber as mentioned above, there are several variants of rubber, each with unique properties. However, most, if not all, rubbers also have some common features, such as:

-

Elasticity:the molecular structure of rubber materials allows them to return to normal shape after compression or tension. This feature is obvious in rubber bands. Stretching or compressing a rubber band temporarily pulls or pushes individual molecules away from each other. When molecules are connected to each other, they return to their original position once the tensile or compressive forces are eliminated.

Industrial chiller units benefit from rubber's elasticity in seals and gaskets.

-

Thermal shrinkage:Rubber shrinks when most materials expand under heat. This unusual phenomenon stems from the reaction of rubber molecules to heat. When heated, the entangled molecules become more entangled and distorted. When the heat is removed, the molecules return to their static state and the rubber returns to its original shape.

Industrial chiller applications require rubber parts that withstand temperature variations.

-

Durability:most rubbers are very durable and can resist abrasion, tear, impact, damage and degradation caused by low temperature and water. They also show a relatively slow rate of heat accumulation.

Industrial chiller systems incorporate rubber components to enhance durability and longevity.

It can be divided into block raw rubber, latex, liquid rubber and powder rubber. Latex is colloidal aqueous dispersion of rubber; Liquid rubber is an oligomer of rubber, which is generally viscous liquid before vulcanization; Powdered rubber is to process latex into powder to facilitate batching and processing. The thermoplastic rubber developed in the 1960s is formed by the processing method of thermoplastic without chemical vulcanization.

Industrial chiller manufacturers frequently use these rubber types for insulation and sealing solutions.

Rubber can be divided into general type and special type. It is an insulator and is not easy to conduct electricity, but it may become a conductor if it is exposed to water or at different temperatures. Conductivity refers to the conduction of electrons of molecules or ions in a substance.

According to the source and method of raw materials: rubber can be divided into natural rubber and synthetic rubber. The consumption of natural rubber accounts for 1 / 3 and that of synthetic rubber accounts for 2/3. According to the appearance of rubber: rubber can be divided into four categories: solid rubber (also known as dry rubber), emulsion rubber (latex), liquid rubber and powder rubber. According to the performance and application of rubber: in addition to natural rubber, synthetic rubber can be divided into general synthetic rubber, semi general synthetic rubber, special synthetic rubber and special synthetic rubber. According to the physical form of rubber: rubber can be divided into hard rubber and soft rubber, raw rubber and mixed rubber.By performance and use: general rubber and special rubber.

Common types of rubber

- Natural Rubber (NR)

- Styrene-butadiene rubber (SBR)

- Butyl (IIR)

- Nitrile (NBR)

- Neoprene® (CR)

- Ethylene Propylene Diene Monomer (EPDM)

- Silicone (Q)

- Viton® (FKM)

- Polyurethane (AU)

- Hydrogenated Nitrile (HNBR)

Various types of rubber are suitable for laser engraving:

- Natural rubber

- Foam rubber

- Synthetic rubber

- Silicon rubber

Laser Cutting Rubber

Laser cutting rubber offers precise cuts that are difficult to achieve with traditional methods. CO2 laser machines can produce gaskets, templates, and other components of varying thicknesses.

Applications include:

-

Seals and gaskets

-

Product parts and brackets

-

Decorative and fashion items

-

Shock absorbers and coasters

For example, Neoprene sheets used in diving suits or industrial applications can be accurately laser cut rubber sheets for professional results.

Applications of Laser Etching Rubber

Laser technology opens many possibilities for rubber processing:

-

Stamp Making: High-precision rubber stamps with detailed designs

-

Office and School Supplies: Custom logos, labels, and seals

-

Industrial Applications: Durable gaskets, printing plates, and markings

-

Creative Projects: Personalized coasters, wristbands, and silicone bottles

With a laser engrave rubber setup, even complex text or detailed images can be processed efficiently and cost-effectively.

Specific applications

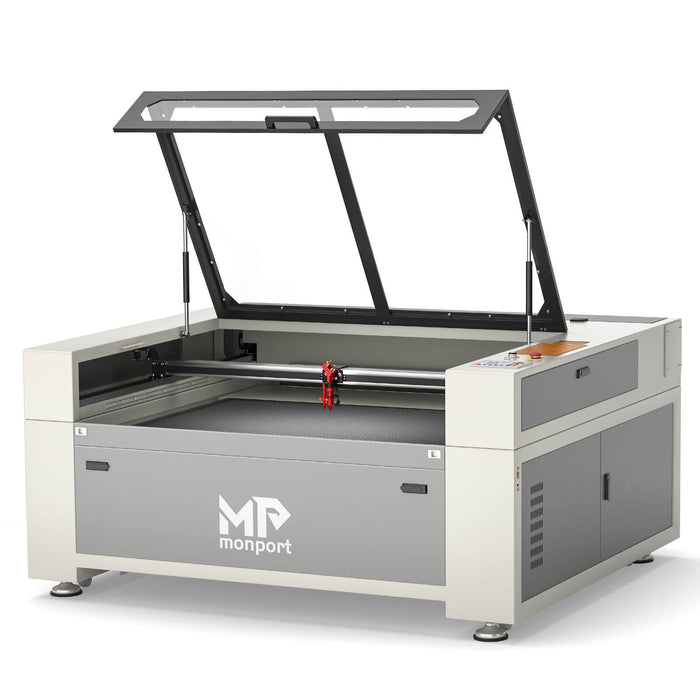

Monport laser system allows efficient and rapid processing of rubber at low cost. Whether you are producing an entire rubber sheet or a single piece, you can significantly reduce production time through an automated process. For example, laser engraving has become the most common method to process rubber stamps, and this technology can also realize the following applications:

- Laser cutting of rubber seals

- Laser engraved wristband silicone

![]()

- Laser engraved silicone bottle

![]()

- Laser engraved rubber stamp

Laser engraving small text, complex signs, and even pictures into rubber is easy to do. Using the Monport laser system, rubber engraving/cutting becomes more efficient, cheap and environmentally friendly. If you want to try laser engraving on rubber, add the Monport machine to your shopping list!

Advantages of Laser Rubber Processing

-

Precision: Achieve clean, accurate cuts and engravings

-

Efficiency: Faster production than traditional methods

-

Versatility: Works with natural, synthetic, and silicone rubbers

-

Eco-Friendly: No chemical use, minimal waste

-

Scalable: Suitable for single items or mass production

FAQs: Laser Rubber Processing

Q1: Can all types of rubber be laser engraved?

A: Most natural and synthetic rubbers, including silicone, can be engraved. Some highly filled rubbers may require testing.

Q2: Does laser cutting rubber produce fumes?

A: Yes, proper ventilation or filters are required to manage odor and smoke.

Q3: Can laser engraving rubber produce fine details?

A: Yes, CO2 laser machines can engrave small text, logos, and intricate designs accurately.

Q4: Is it safe to leave rubber in the laser machine unattended?

A: No, rubber is flammable. Always monitor the process.

Q5: Can rubber engraving be used for commercial production?

A: Yes, laser processing is widely used in stamp making, printing plates, and industrial rubber products.

Final Thoughts

Using a laser etching rubber machine unlocks creative and industrial opportunities. From laser cut rubber for gaskets to laser engraving rubber for stamps and promotional products, the technology offers precision, efficiency, and scalability. Monport laser systems make rubber processing cost-effective, safe, and environmentally friendly.