Are you captivated by the allure of engraved designs on wood? Whether you have a hobby or a business that involves woodworking,the art of engraving on wood can add a touch of elegance and personalization to your creations. If you're ready to explore the world of laser engraving, this comprehensive guide will provide you with the necessary information to get started. From understanding the different wood types and their corresponding laser settings to learning the step-by-step process on how to laser engrave into wood, we will empower you to create stunning designs. And to take your wood engraving journey to the next level, we'll introduce you to Monport's 80W CO2 Laser Engraver & Cutting Machine, a reliable tool with exceptional features designed to meet your engraving needs.

Understanding Different Wood Types and Their Corresponding Laser Settings

Before diving into the fascinating world of engraving on wood, it's important to understand the characteristics of different wood types and how they respond to laser engraving. Here are a few popular wood types and their corresponding laser settings to achieve optimal results:

-

Softwoods (e.g., pine, cedar, spruce): Softwoods engrave with ease due to their lower density. For softwoods, a power wattage of around 40-60W on Monport's 80W CO2 Laser Engraver & Cutting Machine is ideal. Set the engraving speed to approximately 300-500 mm/s for clean and precise results.

-

Hardwoods (e.g., oak, maple, mahogany): Hardwoods require a slightly higher power wattage to achieve deep and prominent engravings. Set the power to around 60-80W on Monport's laser engraver and adjust the engraving speed to 200-400 mm/s for optimal results.

-

Exotic Woods (e.g., teak, rosewood, zebrawood): Exotic woods are known for their unique grain patterns and colors. When engraving on wood like this, experiment with different power settings to find the perfect balance between depth and preservation of the wood's beauty. Start with a power wattage of 60-80W and an engraving speed of 200-400 mm/s.

Remember, these settings serve as general guidelines. It's always important to run tests on scrap wood to fine-tune the settings for your specific project and achieve the desired results.

Step-by-Step Guide to Laser Engraving Into Wood

Now that we've explored the different wood types and laser settings, let's delve into the step-by-step process of engraving on wood:

Step 1: Preparing the Wood

Start by selecting a high-quality piece of wood and ensure it is clean and free from any dirt, debris, or moisture.

Step 2: Design and Software Setup

Create or import your desired design into laser engraving software such as RDWorks or LightBurn. Adjust the size, position, and other settings as needed.

Step 3: Machine Setup

Place the wood piece onto the work bed of Monport's 80W CO2 Laser Engraver & Cutting Machine, ensuring it is securely positioned. Set the focal length according to the thickness of the wood to achieve the desired engraving depth.

Step 4: Test and Calibration

Perform a test run on a scrap piece of wood to ensure the settings are optimized for the desired effect. Make any necessary adjustments to power, engraving speed, or focal length based on the test results.

Step 5: Start Engraving

Begin the engraving on wood process by starting the machine. Monitor the progress closely to ensure the engraving is going according to your expectations.

Step 6: Finishing Touches

Once the engraving is complete, remove the wood piece from the machine and gently clean off any dust or residue. Depending on your preference, you can apply a finish or sealant to protect the wood and enhance the engraved design.

Introducing Monport's 80W CO2 Laser Engraver & Cutting Machine

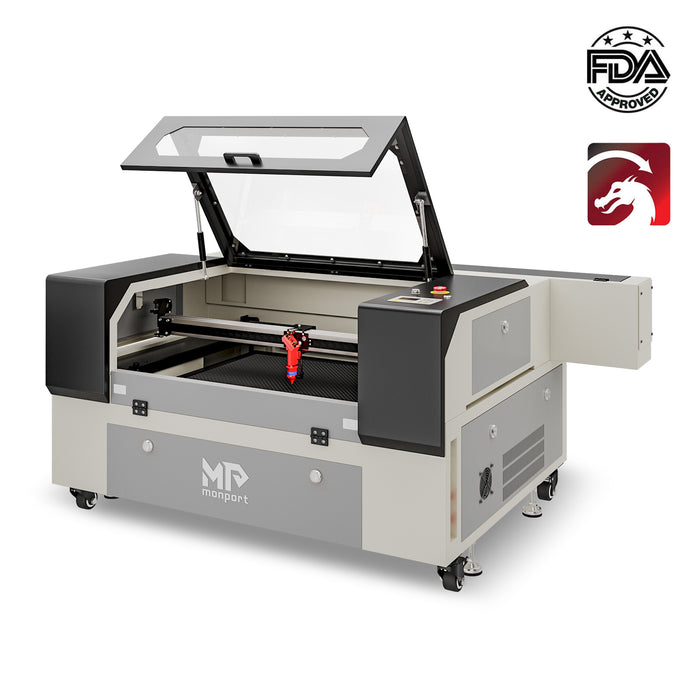

To unlock the full potential of your engraving on wood projects, a reliable and high-performance laser engraver is essential. Monport's 80W CO2 Laser Engraver & Cutting Machine is specifically designed to meet the demands of woodworking enthusiasts and professionals alike. With its precise control, spacious work bed, and compatibility with popular software like RDWorks and LightBurn, this machine ensures impeccable engraving results.

The 80W power wattage, adjustable engraving speed, and four-way pass-through capability of Monport's laser engraver allow you to tackle various wood types with ease. The sturdy construction, featuring a metal honeycomb board and aluminum panel, guarantees stability and durability for all your engraving projects.

Conclusion

Engraving on wood offers endless opportunities to create unique and personalized designs. With the right settings, a high-quality laser engraving machine like Monport's 80W CO2 Laser Engraver & Cutting Machine, and a bit of creativity, you can unlock the beauty of wood and elevate your woodworking projects to new heights. If you'd like to embark on this mesmerizing journey, visit Monport's website today to explore the best deals, gain access to laser engraving tips, and take the first step towards transforming your woodworking creations into works of art.

Start Creating Stunning Engraved Wood Designs Today

With Monport’s 80W CO2 Laser Engraver, your woodworking projects can shine with professional precision.

-

Don’t miss out—get 10% OFF with code

BESTMP10.

- Click here to elevate your craft!