Leather is an exquisite material that exudes class and elegance. Its versatility makes it an ideal canvas for engraving technology,, allowing you to create intricate and personalized laser leatherworking designs. In this comprehensive guide, we will explore the different types of leather suitable for laser engraving, provide the proper laser engraver calibrations and settings for each type, and share essential tips to maintain your laser engraver for leather in top shape. We will also highlight why the Monport 80W CO2 Laser Engraver & Cutter is the best leather laser engraver available in the market, with its exceptional features and capabilities.

A Perfect Match: Leather and Laser Engraving

Leather is a superb material for engraving technology due to its natural texture and durability. The laser beam interacts with the surface of the leather, creating precise and detailed engravings, adding a touch of sophistication to your laser leatherworking projects. Here are the main types of leather that are commonly used in laser engraving:

Full-grain Leather:

Full-grain leather is renowned for its natural, unaltered grain surface, making it the highest quality leather available. It engraves beautifully, creating a striking contrast between the engraved and untouched areas. To achieve the best results, it is recommended to use a lower laser power setting, around 30% to 40% power. This will ensure deep and precise engravings on full-grain leather, producing a classic and rustic look.

Top-grain Leather:

Top-grain leather has a smooth and refined surface, making it perfect for detailed and intricate designs. For top-grain leather, a higher laser power setting of around 50% to 60% is recommended. This will provide the necessary force to achieve precise and crisp engravings on the leather surface. Use lower speeds for fine designs and higher speeds for larger, more open patterns.

Suede Leather:

Suede leather, with its soft and velvety texture, can also be engraved using laser engraving technology. The laser beam creates a unique burnt effect on the surface of the suede, adding depth and dimension to the engraved patterns. For suede leather, it is best to use a lower laser power setting, around 20% to 30%, to achieve the desired effect. Adjust the speed according to the level of detail you want to engrave.

Maintaining Your Leather Laser Engraver

To ensure that your laser engraver for leather stays in top shape and continues to produce high-quality laser leatherworking engravings, proper maintenance is essential. Here are a few tips to keep your machine running smoothly:

-

Clean the lens: Regularly clean the lens of your laser engraver with a soft, lint-free cloth to remove any dust or debris. This will prevent any distortion or loss of laser power during engraving.

-

Check and clean the exhaust system: Make sure the exhaust system is clear and free from any obstructions. Clean the filters and replace them if necessary to maintain proper ventilation.

-

Calibration: Regularly calibrate your laser engraver to ensure accurate and precise engravings. Follow the manufacturer's instructions for calibrating your specific machine.

-

Lubrication: Lubricate the moving parts of your laser engraver, such as the rails and bearings, as recommended by the manufacturer. This will ensure smooth and precise movements.

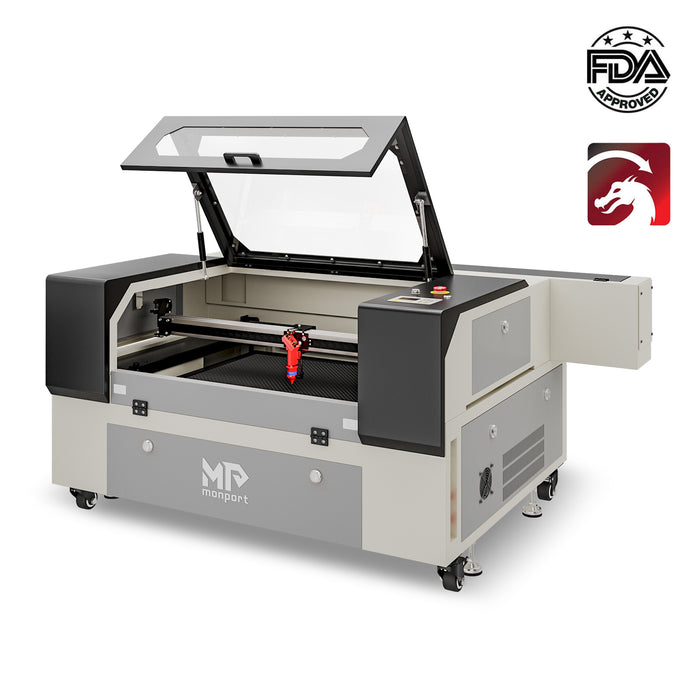

Introducing Monport 80W CO2 Laser Engraver & Cutter

When it comes to finding the best leather laser engraver, the Monport 80W CO2 Laser Engraver & Cutter stands out from the crowd. Here are its remarkable features that make it the ultimate choice:

Spacious Work Bed for Large Projects:

The Monport 80W CO2 Laser Engraver & Cutter features a spacious 20" x 28" work bed, providing ample space for larger engraving projects. Its four-way pass-through design allows for engraving on items extending beyond the work bed.

High Compatibility:

This laser engraver is compatible with both Windows and Mac operating systems, supporting popular design software such as RDWorks and LightBurn. This versatility allows for precise control and engravings on various nonmetallic surfaces, including leather.

High-Performance Laser Beam:

Monport's collaboration with Yongli has produced a high-efficiency laser beam that ensures up to 12,000 hours of operation. The laser beam delivers exceptional results, outperforming competitors with identical laser tube specifications.

Intelligent Control Panel:

Driven by the Ruisin KT332N motherboard, the Monport 80W CO2 Laser Engraver & Cutter offers direct control of auto-focusing, Z-axis movement, and air assistance. The dynamic display of processing trajectory and progress enables easy modification of layer parameters on the control panel.

Comprehensive Safety Features:

The Monport laser engraver prioritizes user safety with features like an emergency stop button, cover protection that stops operation when opened, and auto-stop for low water or high temperature conditions. The built-in ventilation ensures instant smoke removal, while the fireproof window allows for observation during the engraving process.

Conclusion

Laser engraving on leather opens up a world of creative possibilities. From full-grain to suede leather, each type presents unique engraving characteristics. By using the proper laser engraving technology calibrations and settings, you can achieve stunning laser leatherworking engravings on different leather surfaces. Remember to maintain your laser engraver for leather regularly to ensure optimal performance.

When it comes to choosing the best leather laser engraver, the Monport 80W CO2 Laser Engraver & Cutter is unmatched in its capabilities and features. Its spacious work bed, high compatibility, high-performance laser beam, intelligent control panel, and comprehensive safety features make it the ultimate choice for any laser leatherworking leather engraving enthusiast.

Visit Monport's website today to explore the best deals, obtain laser engraving tips, and elevate your leather engraving game with the best leather laser engraver on the market.

Remember, the key to mastering leather laser engraving techniques lies in choosing the right machine and understanding the unique characteristics of each type of leather. With the Monport 80W CO2 Laser Engraver & Cutter, you can bring your creative visions to life on the timeless canvas of leather. Don't miss out on this opportunity to create truly remarkable leather creations.