Laser Engraving & Cutting Materials

How to Prevent Burning When Laser Cutting

Because of the material of wood and the common nature of wood in the laser engraving industry, it is very important to prevent the burning marks produced by wood engraving. A very good wood carving craft must be able to do clean and tidy carving. Wood carving will generally have a feeling of being burned, with the wood base color matching has a kind of original artistic beauty, the color depth mainly depends on laser power and engraving speed. But some wood is usually the softer kind, and you can't change the color anyway. Sometimes the client may ask you to color the finished product. Acrylic paint can be used.

Read moreLaser Engraving & Cutting Materials

Laser Cutting & Engraving Foam

During the engraving process, pay attention to the exhaust measures, and there must be sufficient flow to remove the gas and particles generated during the laser processing in the foam laser engraving, cutting and marking equipment. Therefore, you need to be equipped with air assist to provide an air flow near the laser focus to help remove the gas and particles generated in the process of foam laser engraving, cutting and marking. Since foam is generally made of synthetic chemical materials, the chemical fumes or solid wastes generated during the cutting process need to be treated by the filtration system before being discharged into the external environment, which is for the health and safety of the carver and the working environment.

Laser Cutting&Engraving laminates

Laser engraving and cutting laminates is an effective way to combine affordability with high-quality results. Laminates, made of multiple layers, come in various types like external, flexline, and reverse laminates, each offering unique benefits. This article outlines tips on engraving techniques using an 80W laser engraver, ideal for precise applications like signage, furniture, and industrial parts. Following key steps such as testing materials, adjusting speed, and focusing the laser can enhance the durability and appearance of the finished product. For those considering laminate engraving, the Monport laser system is an efficient and cost-effective solution.

Laser Cutting & Engraving Delrin/POM

Delrin, or POM, is a versatile thermoplastic known for its strength, dimensional stability, and resistance to moisture and chemicals. Ideal for gears, hinges, and industrial parts, Delrin excels in laser cutting and engraving, producing smooth, precise edges. Industries like automotive, electronics, and consumer goods rely on Delrin's durability, ease of processing, and low friction. Monport laser machines ensure efficient cutting and engraving of this material, making it perfect for high-precision applications.

Laser Etching & Engraving Glass

Laser etching and engraving on glass have become popular for creating custom designs like logos and patterns, especially in industries like wineries and custom glassware. Using Monport Laser systems, both etching and engraving techniques offer precision, flexibility, and no consumables. Etching melts the material’s surface to create raised marks, while engraving cuts into it for deeper, tactile designs. A rotary attachment allows engraving on cylindrical glass objects like bottles and glasses. Monport's technology ensures repeatability, speed, and no need for masks or templates, making it ideal for both small businesses and personal use.

Why we recommend laser marking on food?

Revolutionize your food packaging with laser marking! Learn how this innovative technology improves sustainability, food safety, and product traceability. Explore the benefits and advantages with Monport.

Laser Cutting & Engraving Fabric and Textile

Laser cutting and engraving have transformed fabric crafting, making it easier than ever to create intricate designs on textiles. With Monport, you can explore precision textile laser engraving and a wide range of laser fabric methods to craft garments, décor, and accessories with unmatched accuracy. Whether you work with natural fibers like cotton and silk or synthetic fabrics like polyester and felt, Monport’s laser textile solutions empower you to achieve professional results every time. Many creators also appreciate how fabric laser cutting and fabric laser etching help produce clean patterns without the stress of manual trimming. Even beginners can try engraving on fabric or simple cloth engraving to see how flexible laser engraving on fabric can be. Fabrics, also called textiles, are woven or knitted materials made from natural fibers such as cotton, wool, or silk, or synthetic fibers like polyester and nylon. Laser textile cutting is compatible with most fabrics, providing clean, precise edges and enabling intricate designs that traditional cutting methods cannot achieve. Some users prefer laser for cutting fabric because of its accuracy, while others enjoy experimenting with laser etching fabric on different garments. Cotton Silk Silk is delicate and thin, making it easy to cut with laser textile technology. The edges may still fray, so careful handling is required. Complex designs should avoid very small shapes, and testing settings on scrap silk is recommended to prevent tearing. Some designers test textile laser engraving on silk for soft, shallow marks, though gentle power settings are always needed. Felt Felt is thick and stable, making it ideal for laser textile cutting. Synthetic felts melt slightly at the edges, sealing them and preventing fraying. Natural felts like wool require precise laser focus for clean edges. Laser textile cutting enables durable, consistent results on felt that scissors cannot match. Felt is also one of the easiest materials for laser etching fabric or trying cloth engraving for signage, keychains, or small crafts. Polyester Polyester is strong, versatile, and melts slightly when cut, sealing edges for a clean finish. Laser textile cutting polyester is ideal for banners, flags, and garments requiring durable, fray-resistant edges. Polyester also reacts well to laser engraving fabric because the heat creates a clear contrast on the surface. Tips for Laser Textile Cutting Laser cutting fabrics requires preparation, attention to fiber content, and proper setup. Here’s how to get the best results with laser textile technology. When working with garment laser cutting, many hobbyists also test their fabric first because different weaves respond differently. The same applies when trying laser cloth or engraving on fabric for small decorative projects. Check Fiber Content Always know your material. Avoid PVC and understand how natural versus synthetic fibers behave under a laser for cutting fabric. Keep Fabric Flat Iron or wash fabrics as needed. Secure them with tape or magnets to prevent movement during cutting. Test Settings Run test cuts on scrap pieces to adjust laser power, speed, and focus. This prevents damage to your main project and is especially important for fabric laser cutting or laser etching fabric. Import Your Design Ensure design files are compatible with your laser software. Test complex patterns before full-scale cutting. Fix Your Project Secure the fabric, verify placement, and let the laser handle precise cutting for professional results. These steps are essential whether you're doing textile laser engraving, laser engraving on fabric for patches, or even garment laser cutting for clothing businesses. Monport provides the expertise, guidance, and support to optimize these processes, making laser textile cutting accessible and efficient for both hobbyists and professionals. Common Applications of Laser Textile Cutting Laser textile cutting opens new creative possibilities across industries and personal projects. Typical applications include laser fabric designs for fashion, cloth engraving for décor, or textile laser engraving on custom banners. Fashion and Clothing Garments, lace patterns, and sportswear. Many brands now rely on garment laser cutting for accuracy and style. Digital Engraving on Fabric Custom banners, flags, and decorative textiles using laser engraving on fabric and fabric laser etching techniques. Toys and Crafts Plush toys, ornaments, and creative projects. Felt toys especially respond well to laser etching fabric. Home Textiles Curtains, pillows, sofas, and decorative items often use laser fabric cutting or laser cloth finishing for precise edges. Floor Coverings Carpets, mats, and large-scale textiles. Specialty Projects Sails, parachutes, tents, and aviation fabrics. In some cases textile laser engraving is used for labeling or marking. Monport’s laser textile solutions make it possible to cut complex fabrics efficiently, with precise edges and minimal fraying, enhancing both the quality and creativity of your projects. Frequently Asked Questions (FAQs) Q1: What fabrics can be safely cut with a laser textile system? A: Cotton, silk, felt, polyester, and most synthetic blends are safe for laser textile cutting. PVC should never be cut due to harmful fumes. Most of these materials also work well with fabric laser cutting or trying laser engraving cloth for small designs. Q2: Does laser textile cutting prevent fabric edges from fraying? A: Synthetic fabrics like polyester and synthetic felt melt slightly during cutting, sealing edges. Natural fabrics like cotton or silk may require additional finishing to prevent fraying. Q3: How do I prepare fabric before laser textile cutting? A: Check fiber content, wash and iron if needed, and lay the fabric flat. Secure it with tape or magnets for clean, precise laser textile cuts. This applies whether you're doing garment laser cutting or basic cloth engraving. Q4: What settings should I use for delicate fabrics like silk? A: Use lower power settings and avoid very small or complex shapes. Always test on scrap fabric first to prevent tearing. Laser etching fabric on delicate materials needs extra caution. Q5: What are some common uses for laser textile cutting? A: Fashion, sportswear, banners, plush toys, household items, carpets, and large-scale applications such as sails, parachutes, and tents. These projects often combine laser engraving fabric and fabric laser cutting depending on the design. Conclusion Laser textile cutting allows designers and crafters to explore unparalleled precision, speed, and creativity. With Monport’s expertise and support, you can achieve professional results across cotton, silk, felt, polyester, and other fabrics. By understanding fiber behavior, preparing your materials, and testing your designs, every laser textile project can meet high standards of quality and creativity. Whether you're working on textile laser engraving, fabric engraving, or trying laser for cutting fabric for the first time, the technology opens endless creative doors. Explore Monport’s solutions today and elevate your fabric projects with precision and efficiency. Unlock big savings using code BESTMP10 at checkout – start transforming your textile designs into laser-cut perfection!

Laser Cutting & Engraving Acrylic

Laser cutters for cutting and engraving cast and extruded acrylic Special Offer | Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus Acrylic is a favorite for most laser engraving enthusiasts thanks to its numerous benefits. The laser machine can cut smooth, polished edges, and can also engrave a bright matte white effect. It is affordable and has a high-end appeal. Last but not least, acrylic can be used to make a variety of products, including but not limited to signs, key holders, and awards. Ⅰ. What do you need to know about engraving acrylic? Before trying to use a laser to cut acrylic, it is very important to understand the different acrylic materials. Acrylic can be divided into transparent board, semi-transparent board (including back panel transparent board), color board (including black and white board and color board) according to the light transmittance; According to the performance, it can be divided into anti-impact board, anti-ultraviolet board, ordinary board and special board such as high impact board, flame retardant board, frosted board, metal effect board, high wear-resistant board, light guide board, etc. According to the production process, acrylic plates are divided into cast plates and extruded plates . Acrylic casting plates are made by pouring liquid acrylic into molds of various shapes and sizes. Most of the medals you see in the market are made of this type of acrylic. Acrylic casting plate is an ideal material for engraving, because it will become matte white when engraving. You can use a laser machine to cut acrylic cast plates, but you cannot form edges with polished surfaces. This type of acrylic material is more suitable for engraving. Another type of acrylic material is acrylic extruded sheet, which is a very popular cutting material. Acrylic extruded plates are made through mass production processes, so their prices are usually lower than acrylic cast plates, and when laser beams are used to cut this material, the effect produced is quite different. The acrylic extruded sheet is cut very clean and smooth, and will produce polished edges during laser cutting. However, it will not produce a matte white effect when engraving, but will form a fairly clear engraving pattern. In conclusion: The extruded plate uses granular raw materials, which are extruded after being dissolved at high temperature, while the cast plate is directly cast with MMA monomer (liquid). Although the extruded plate is relatively flat and smooth in appearance, it is because it is formed when the granular raw material is formed. To complete the polymerization. When processed into plates, its structure and performance are weak, and it is not suitable as a material for outdoor marking products. It is only suitable for indoor products such as crystal letters or product brackets. In addition, since most of the extruded panels do not have the function of UV protection, their outdoor use life is not the same as that of the cast panels. The color will gradually fade and it is easy to become brittle until it breaks. The casting plate is to complete the structural polymerization during the processing of the plate, during which the ultraviolet absorber is added, which has extremely high strength and UV function, and the outdoor service life is more than 5 years or even 10 years. During the use, the color is always bright as new. Ⅱ. How to engrave acrylic(suitable settings)? Compared with the usual cut plywood, the cutting of acrylic does not seem to be as simple as imagined. For the best results, it is not necessary to follow the cutting parameters of the wood. In order to cut the acrylic to be flat and smooth, the edges are not white and the honeycomb panel is not reflective, we have carried out a simple analysis on the test of this acrylic cutting as follows: MACHINE: One MONPORT 80W Co2 Laser Engraving & Cutting Machine MATERIAL: 6mm thick acrylic PARAMETER SETTINGS: Cutting speed: 8mm/s Cutting power: 65%—70% Cutting focal length: 5mm The power is set to 65%-70% Set the minimum power and maximum power because the speed when cutting a straight line is faster than the speed at the corner. We said that the faster the speed, the shallower the cutting. Therefore, in order to be able to cut through the sample, we usually set the minimum power and maximum power. The speed is set to 8mm/s We all know that the faster the speed, the higher the processing efficiency, so we will increase the power as much as possible to increase the speed when cutting general materials, but the acrylic is different, too fast speed will make the cutting surface not smooth and appear uneven Sense, so in order to cut a smooth effect. We need to keep in mind when setting the parameters: increase the power and reduce the speed. Do not blow when cutting Many people have the problem of whitening the cut surface when cutting acrylic. This is because he uses air blowing when cutting, so if you want to cut a smooth effect, please turn off the air blowing. At the same time, please remind everyone. When cutting acrylic without blowing air, please be guarded by the side. Because there is no flame retardant of strong blowing, the material is easy to catch fire during the cutting process. If you find a fire, please turn off the machine in time. Overhead cutting When cutting acrylic, if we want to avoid the problem of edge melting caused by the reflection of the honeycomb panel, we can solve it by overhead cutting. In summary, we know that when cutting 6mm acrylic, we might as well set the power to 65%—70% and the speed to 8mm/s. At the same time, choose not to blow during the cutting process, and you can use it when appropriate The overhead cutting method is used to solve the reflection problem of the honeycomb panel; of course, but we want to cut the frosted effect, we only need a simple step, that is, turn on the air blow, so that the cut acrylic will have a kind of frosted It worked. Ⅲ. Applications of Laser Cutting & Engraving Acrylic. Awards: Awards are the main application of acrylic. As mentioned, there are many options to choose from. One of the most popular acrylic award applications is the trophy. Manufacturers can also add color to the transparent acrylic trophy in a variety of ways. The back of the awards can be painted, screen printed or digitally printed in color, marble, geometric or other interesting patterns, and then reverse engraved to create amazing awards. These unique award decorating options are a cost effective way to customize your trophy and enhance your brand. Ideal solutions for tight timelines wanting custom awards and large organizations or awards ceremonies. Display Fixtures: For many reasons, acrylic is an excellent material choice for display devices. Its optical clarity can easily transmit light, so that the objects placed behind or wrapped in it are very clearly visible. Acrylic also tends to highlight the product, rather than the case or the display stand itself, it provides a professional and elegant display. Desk accessories: Desktop accessories can be used as gifts as well as rewards. There is no shortage of products provided by suppliers or products you can make yourself. In addition to clipboards, letter openers, coaster sets, and rulers, you can also consider acrylic nameplates, table poles, pen holders, and paperweights of almost any shape. The durability of acrylic is an attractive feature of such items, as they often wear out a lot. Frame: People's fascination with photos continues to grow, and people often use photo frames to display photos of family, friends, and colleagues at home and in the office. Acrylic is an excellent material for making photo frames, because it can be made into any shape and style, from easel-style frames to four-sided cube frames, to frames that fit photos between two pieces of acrylic. Business card: The business card is also a popular application made of acrylic. This beautiful acrylic material is 3mm thick, can accommodate double-sided laser engraving, and provides a variety of color options to meet the needs of your company. There are colorless crystal, transparent acrylic, translucent black, blue, fluorescent green and fluorescent orange. Acrylic cards can be double-sided laser engraved.. The above is the content and steps of our acrylic engraving. Is it very simple? Next, let us start your acrylic engraving journey with Monport!

Laser Cutting & Engraving Wood

Unleash your creativity with wood laser engraving! Learn how to choose the right wood, optimize laser settings, and create beautiful projects. Explore the possibilities with Monport laser engravers.

Laser Engraving & Cutting Paper

Laser engraving and cutting paper opens up endless creative possibilities, transforming ordinary materials into stunning works of art. With the right tools and techniques, you can create intricate designs, personalized cards, decorations, and more. In this guide, we explore the best practices, paper types, machine settings, and creative project ideas for laser engraving and cutting paper using a Monport 80W CO2 laser. Ⅰ. Why Paper is One of the Most Versatile Materials Paper is a surprisingly versatile material for laser engraving and cutting. Despite being thin and flammable, it can produce clean, precise, and detailed results when used with the proper settings. Advantages of using paper: Easily obtainable and affordable Available in various colors, textures, and thicknesses Works well for both practice and professional projects With the Monport 80W CO2 laser, you can cut or engrave paper without burning, making it ideal for artistic and practical projects. Ⅱ. Types of Paper for Laser Engraving and Cutting Choosing the right type of paper is crucial for optimal results. Here’s a breakdown of commonly used types: Recommended Paper Types Copy Paper Medium-weight, usually white Affordable and easy to use for practice Works well for simple designs when paired with cardstock support Coated Paper Glossy or enamel paper with mixed polymers Can be laser cut cleanly with correct settings Construction Paper Slightly thicker craft paper Ideal for school projects and decorative designs Cardstock Thicker and harder than standard paper Perfect for greeting cards, 3D paper crafts, and personalized gifts High ignition point prevents burning during cutting Paper Not Recommended Toilet Paper: Too thin and flammable; not suitable for laser cutting Ⅲ. Tips for Laser Engraving and Cutting Paper To ensure clean results: Reduce power for engraving: Paper is fragile, so lower power prevents tearing or burning. Use air assist carefully: Prevents smoke buildup but avoid blowing paper away. Prevent shifting: Secure lightweight sheets with small weights or tape. Layer thin paper: Place cardstock under copy paper for stability. Recommended Machine Settings (Monport 80W CO2 Laser) Engraving Cardstock: Speed: 800 mm/s Power: 10–15% Cutting Cardstock: Speed: 100 mm/s Power: 15–25% Following these settings ensures clean cuts, smooth edges, and fast results. Ⅳ. Creative Projects Using Laser-Cut Paper Laser engraving and cutting paper allows you to create unique, high-quality designs for any occasion. Here are some ideas: Wedding Invitations: Elegant, precise designs with custom fonts Birthday Cards: Personalized messages and intricate cut-outs Cut-Paper Art: Decorative scenes or miniature 3D art Decoupage Projects: Layered paper art for home decor Holiday Decorations: Christmas reindeer scenes, ornaments, or wall hangings Personalized Gift Cards: Add names, designs, or images with detailed laser cuts With paper cutting machine laser, your projects are fast, precise, and professional-looking. Ⅴ. Safety Considerations Paper is highly flammable and lightweight. Keep these safety tips in mind: Always monitor the laser while cutting or engraving Use proper ventilation to prevent smoke accumulation Wear laser protective glasses if needed Use weights or tape to prevent paper from moving Ⅵ. Enhance Your Projects with Monport Black Laser Marking Spray For laser engraving on metal or hybrid projects, the Monport black laser marking spray ensures high-contrast, permanent marks. It works seamlessly with CO2 laser engraving machines for professional results. How to use: Clean the surface with alcohol Shake the can for 2 minutes Spray 6–8 inches away Let dry for 5 minutes Engrave and rinse Ideal for metal, glass, or mixed-material projects to complement your paper designs. FAQs About Laser Engraving and Cutting Paper What paper is best for laser engraving and cutting? Cardstock is ideal due to its thickness, hardness, and high ignition point. Can I use copy paper? Yes, but place a cardstock layer underneath to prevent damage. How do I prevent paper from moving? Secure edges with tape or small weights; avoid obstructing the cut area. What are optimal settings for cardstock? Engraving: 800 mm/s, 10–15% power Cutting: 100 mm/s, 15–25% power What projects can I create with laser-cut paper? Wedding invitations, birthday cards, decoupage, cut-paper art, and personalized gift cards Conclusion: Unleash Creativity with Laser-Cut Paper With the Monport 80W CO2 laser and proper techniques, even ordinary paper can become extraordinary. By selecting the right paper, adjusting your settings, and exploring creative projects, you can achieve precise, clean, and stunning results every time. Key Takeaway: Paper is versatile, accessible, and perfect for laser engraving. Combine it with a high-quality laser cutter like Monport 80W CO2 and your imagination to create unique, professional projects. Shop Now & Save: Enter code BESTMP10 at checkout to elevate your paper engraving projects with Monport!

Laser Marking & Engraving Metal

Ⅰ.Metal-with high thermal conductivity and conductivity Metal is an important material, used everywhere in our lives. Not only for space shuttles and space stations, but also in widely used products like Apple phones, metal studs on girls’ ears, and boys’ metal belt logos. Metal has penetrated into our food, clothing, housing, and transportation, and metal products occupy a very important position. Trademarks, barcodes, and numbers on metal products are generally used for identification marks, usually directly machined on the surface, such as stamping, laser engrave, punching, etc., to form marks, or they are generated by external processing methods such as printing and sticking labels. Metal materials are usually divided into ferrous metals, non-ferrous metals and special metal materials. Ferrous metals, also known as iron and steel materials, include industrial pure iron with total impurity content less than 0.2% and carbon content no more than 0.0218%, steel with carbon content of 0.0218% ~ 2.11%, and cast iron with carbon content greater than 2.11%. Ferrous metals in a broad sense also include chromium, manganese and their alloys. Nonferrous Metals refer to all metals and their alloys except iron, chromium and manganese. They are usually divided into light metals, heavy metals, precious metals, semi metals, rare metals and rare earth metals. Nonferrous alloys generally have higher strength and hardness than pure metals, high resistance and low resistance temperature coefficient. Special metal materials include structural metal materials and functional metal materials for different purposes. There are amorphous metal materials obtained by rapid condensation process, quasicrystal, microcrystalline and nanocrystalline metal materials, etc; There are also special functional alloys such as stealth, hydrogen resistance, superconductivity, shape memory, wear resistance, vibration damping and metal matrix composites. Knowing suitable metals is essential for you to understand how to laser engrave metal. Engraver machine with fiber lasers are most suitable for marking all types of brass, copper, aluminum, stainless steel, and nickel-plated metals, as well as engineering plastics such as polycarbonate. Aluminum is one of the best and most common metals used in engraver machine, and brass and copper are also ideal because both metals have good heat transfer capabilities. Tungsten and cemented carbide are the hardest metals on earth, so engraving or etching is generally not recommended. Here are some metals that you can engrave with a high-efficiency fiber engraver machine. Suitable metals for laser marking and engraving: Stainless Steel Aluminum Anodized aluminum Hardened metals Alloyed steels High-speed steels Titanium, titanium alloys Brass Copper Precious metals (e.g. silver, gold) Coated metals Ⅱ. How to engrave/mark metal ? Black marking is a marking process that produces high contrast, all-black marks. The surface of this structure reduces the amount of reflected light and presents dark, matte blackening marks, which remain consistent from any point of view. This makes the mark non-abrasive. All-black marking is an ideal choice for laser engrave on materials such as stainless steel, titanium, copper, and brass, creating durable and visually striking identification or decorative marks using an engraver machine. Now many optical fiber laser marking machines need to present black when marking metal, so how can we use an engraver machine to print black on metal? How should parameters be set? Let me give you a brief explanation. Parameter setting takes the stainless steel marked by Monport laser 20W fiber laser marking machine as an example: MACHINE: MONPORT 20W FIBER OPTIC SPLIT MARKING MACHINE MATERIAL: One piece of the stainless steel PARAMETER SETTINGS(Marking): Marking speed: 100-200mm/s Marking power: 50%—70% After importing the vector map, select fill in the blanks The focus deviation method is adopted for print black, which is generally ± 1-2mm away from the focus In the actual marking process, because the specific optical fiber laser marking machine used is different, the specific setting of parameters is different, so we should master the principle of setting parameters in this way. Why set parameters like this? Because the smaller the filling, the darker it will be, the lower the speed, the darker it will be, the greater the power, the darker it will be, the more accurate the focal length, and the darker it will be, but it is not that the slower the speed or the greater the power, the better, because too much energy consumption will affect the service life of the laser. This is the basic parameter and principle of fiber laser marking machine when marking black metal. You can try and adjust it according to your actual situation. Ⅲ. Applications for engraving / marking metal Laser marking is widely used for graphics and text marking in many fields such as integrated circuit chips, computer accessories, industrial bearings, clocks and watches, electronic and communication products, aerospace devices, various auto parts, household appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military affairs, as well as mass production line operation. Automobile industry The automotive industry has become one of the largest users of this technology. It is estimated that a car is composed of approximately 30,000 parts, which are made of steel, aluminum, copper, special fibers or plastics, and vary in shape and size. For example, mark the seat belt components with information such as country of origin, serial number, and bar code. You will also find fiber laser markings on engine blocks, car sensors, chassis VIN numbers, and motorcycle parts. All these applications are achieved by using a fiber laser marker in the automotive industry; One of the industry's biggest concerns about marking is readability and traceability. Parts should be traced back to their country of origin, and the markings should be machine-readable. It is for this reason that the use of fiber lasers has increased recently. Electronics Industry In such a fast-growing industry, it is vital to put efficiency first and meet ever-increasing demand. This demand also expects quality and safety too. TVs, Laptops and smartphones are all made up of tiny and small substances. Fiber laser marking is the most effective marking method in this industry because it can handle tiny elements without damaging surrounding materials. Medical industry Health institutions and medical equipment manufacturers have very strict standards in the location, size and content of the marks, so there is no room for error. And markings must be resistant to withstand acid cleaning, corrosion and sterilization, and high temperatures. Medical tools are becoming smaller and process more efficient. But high quality and safety are still the top priorities of the industry. Therefore, considering quality, cost-effectiveness, speed, reliability and adaptability, fiber lasers have become a popular choice for marking in this industry. The following are some of the most common reasons why fiber laser marking is used in the medical industry: Traceability of medical equipment: Internal medical staff of health institutions need to be able to track and locate medical equipment in their hospitals. They should also be able to clearly read and identify each instrument during the sterilization process. Recognition of medical prostheses: Medical prostheses need to have a medical number or logo based on an alphanumeric series retrieved from a dedicated database. Here are some specific applications: Bar codes QR codes Branding Logos Identification Traceability Serial numbers/codes Two-dimensional matrix code Product information/product name Graphics and designs UDI Medical Marking Personalized customization Well, after reading this article, do you know more about laser marking metals? Is it very simple? Come on! Let’s try the Monport laser marking machine to start your journey of metal marking!

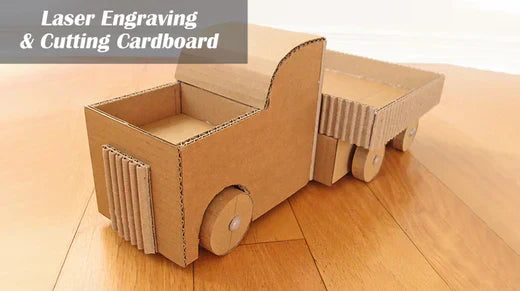

Laser Engraving & Cutting Cardboard

Cardboard is one of the most cost-effective and versatile materials for laser cutting. Its lightweight, affordability, and ease of transport make it ideal for projects like packaging, crafts, and custom designs. With the Monport 80W CO2 Laser Engraver, you can create intricate cuts and engravings effortlessly!

Laser Engraving & Marking Ceramic

Ⅰ. Excellent durable & refractory material-Ceramic What is ceramic? Ceramics are any of a variety of hard, brittle, heat-resistant, and corrosion-resistant materials, which are formed by molding inorganic non-metallic materials (such as clay) and then firing them at high temperatures, often enhanced by techniques like black laser marking spray to achieve detailed engravings on ceramic surfaces. Common examples are pottery, porcelain, and bricks. When it comes to engraving ceramics, laser engraver software allows for precise customization, enabling the addition of intricate designs and personal touches to these materials. Whether you're engraving a tile for home decor or creating a unique gift, laser engraving ceramic provides the tools to translate your creativity into stunning designs. Ceramic is the collective term for pottery and porcelain. Traditional ceramics, also known as ordinary ceramics, are products made from clay and other natural silicates as the main raw materials. Modern ceramics are also known as new ceramics, fine ceramics, or special ceramics. Commonly used non-silicate chemical raw materials or synthetic raw materials, such as oxide (alumina, zirconia, titanium oxide, etc.) and non-oxide (silicon nitride, boron carbide, etc.) manufacturing. Ceramics have many advantages such as excellent insulation, corrosion resistance, high-temperature resistance, high hardness, low density, and radiation resistance, and have been widely used in various fields of the national economy. With the use of laser engraving ceramic, products can be precisely engraved for a variety of applications, including industrial art ceramics and personalized decorative items. The rise of high-tech industries and the integration of laser engraving ceramic has enabled ceramics to become even more versatile, allowing for intricate designs and detailed markings that were previously difficult to achieve, especially with the addition of black laser marking spray for enhanced contrast and precision. They now have higher temperature resistance, mechanical properties, special electrical properties, and excellent chemical resistance than traditional ceramics. There are three basic types of ceramic, earthenware, porcelain and stoneware. These three differ depending on the clay used to make them and the heat required to fire them. Earthenware Earthenware is considered to be the oldest form of pottery, dating back to the Stone Age. Even though the composition of this pottery may be very different, the usual composition is 25% ball clay, 32% quartz, 28% kaolin and 15% feldspar. Pottery is considered the softest pottery, fired at the lowest temperature. It absorbs water, is porous and scratches easily. The classification of this type of earthenware takes into account all ancient pottery, terracotta warriors, Chinese and Japanese pottery from the 16th century and later, and pottery from Europe to the 17th century. In particular, it considers Delft or faience in tin-glazed pottery. The best example of fine art pottery is the Chinese clay warriors, also known as terracotta warriors. To make it waterproof, they wrapped it in a glassy liquid called vitreous and then re-fired in a kiln. Clay contains iron and can be used to make pottery. Depending on the amount available during the firing process and the oxygen content in the kiln, it can provide shades ranging from light yellow to cream, deep red, black or gray. This type of pottery can be as thin as porcelain, not as tough and strong, but more porous than stoneware. Generally speaking, this type of pottery is fired at a high temperature of 1000 to 1200 degrees Celsius. Stoneware This kind of pottery has a dense texture and has stone-like properties when heated; this is why it is called stoneware. This kind of pottery is impervious or waterproof, and is usually opaque. Under natural conditions, it is gray; however, it will turn brown due to the firing process, and then a different color may be used in the glaze type. Generally speaking, this type of pottery is fired at a high temperature of 1000 to 1300 degrees Celsius. This is used to make commercial goods. On the other hand, it is also favored by famous artists in making art pottery. The first stone tools were made during the Shang Dynasty in China. First, it appeared in Germany in the fifteenth century. Later, in the 17th century, an English potter first began to make salt-glazed stoneware. This development occurred in the 18th century, when a man named Josiah Wedgwood made black stoneware or basalt and jasper or white stoneware. Porcelain The difference between stoneware and porcelain is blurred. Ceramic artists from China define porcelain as a kind of pottery, which will sound a bell once it is struck. On the other hand, in the West, porcelain is distinguished from stoneware due to its translucent characteristics. Stoneware is different from porcelain because it is opaque and is usually only partially vitrified. It is fired at high temperature. China is the main producer of porcelain. It appeared in the Han Dynasty, or possibly in the late Tang Dynasty, using white china clay or kaolin and feldspar rock or ground dwarf stone. On the contrary, development took place in Song Dynasty, Yuan Dynasty and Ming Dynasty. Potters in the 16th century tried to reshape the extraordinary translucency of glass by putting it in clay, thereby creating a form called soft porcelain. However, the hard and true forms of Chinese porcelain were not discovered until Germany, especially in Dresden and Meissen in the 1700s, when the famous potter Ehrenfeld Walter Von and the alchemist Johann Friedrich Shey Boteger started to use feldspar rock instead of glass. The evolution of porcelain and its potential for intricate designs also benefits from modern advancements, such as black laser marking spray, which enhances contrast for delicate engraving on porcelain surfaces. Ⅱ. How to engrave ceramic? Choosing the material is the first step in making ceramics or pottery. According to needs, beginners can start with a ceramic tile. As usual, our Monport laser takes a piece of 8mm blue ceramic tile for a experiment for laser engraving ceramic: Applicable parameter settings for ceramic: MACHINE: MONPORT 80W CO2 Laser Engraving & Cutting Machine MATERIAL: One piece of 8mm blue ceramic tile PARAMETER SETTINGS(ENGRAVING): Engraving speed: 20 mm/s Engraving power: 85%-100% Other Methods: Spray black paint on the white tiles, and then use a laser to burn off the paint, exposing the tiles below. This produces a rich black image, and you can even use another color underneath (for example, apply a layer of red paint, let it dry, and then cover it with black spray paint). Norton method: The obvious advantage of this method is that it is permanently etched on the tile glaze and cannot be scraped off. The disadvantage is that the black is not very deep, it is more like a dark gray. Unless you want a more uniform gloss (and slightly enhance the black), no surface treatment is required. The method involves applying a thin layer of white spray paint on the tiles, then etching the image and then using acetone to remove all the white paint. Ⅲ. Applications As mentioned above, ceramics are everywhere and play an important role in people's daily lives. Ceramics can be used in various utensils, such as utensils. Marble memorial plate slab Marble slabs are cut and polished to fix the angel statue. The marble slab is laser engraved to create grooves with letters. Then fill the letter passages with black fonts, which contrasts sharply with the white Carrara marble. The laser engraving on the marble is finished by CO2 and fiber laser machine and manual rotary finishing. If the size of the slate is larger, you can also choose to sandblast the marble. Ceramic Cups with logo A custom ceramic cup filled with coffee, tea, or cocoa will make your company logo shine. There are many choices of personalized ceramic coffee cups, in various colors and styles. Promotional mugs with imprints are cheap and durable, allowing your brand to remain in front of them for many years. The customized coffee cup can also be used to serve tea and cocoa, and it is a good corporate promotion idea to match with a beverage bag! With laser engraving ceramic, along with black laser marking spray, you can achieve intricate, permanent designs on the ceramic surface, ensuring your logo stands out even more. Customized flowerpot laser marking on ceramics The ceramic flowerpots made in Germany are of high quality, so their coating will turn dark gray when laser engraved, which has a good decorative effect. The laser-engraved logo or text will be permanent and will not be removed by any chemicals or storage conditions. The laser-engraved artwork has also become part of the material it is engraving (in this case, the ceramic jar) for the Brooklyn marketing agency, and will be used as film and commercial props. Personalized Memorial Stone Personalized gifts are always remembered. You can add and engrave any information on any surface, whether it is stone, metal, glass or plastic, we can always do the job. With the right laser engraver software, you can easily create detailed and customized designs for ceramic items. One of the countless ways to customize and personalize a tile is to engrave it. You can engrave any image or text on the tile, install it in your home as part of the decoration, or give it as a gift. Engraved tiles can stand on their own or become part of a larger design installation. Now, find a suitable material to start your first attempt at laser engraving ceramic, and with your laser engraver software, you can create your masterpiece! For enhanced results, consider using black laser marking spray to create sharp and permanent engravings, making your designs even more vibrant and lasting. FAQs What materials can Monport laser machines process?Monport laser systems can handle a wide range of materials, including wood, acrylic, metal, leather, and glass, making them perfect for versatile engraving and cutting projects. What are the key advantages of Monport CO₂ laser engravers?Monport CO₂ lasers deliver outstanding precision, spacious work areas, and strong cutting power—ideal for makers, crafters, and small businesses. Why should I consider a Monport fiber laser?Monport fiber lasers are designed for exceptional speed and precision, making them the go-to choice for metal engraving and industrial-grade applications. Are Monport machines suitable for beginners?Absolutely. Many Monport models arrive fully or partially assembled and feature user-friendly controls and step-by-step tutorials for a smooth setup experience. What sets Monport apart from other brands?Monport stands out with its competitive pricing, robust construction, and excellent software compatibility—making it a smart choice for both beginners and professional. Celebrate Business Week with Monport! Enjoy up to 30% OFF on our premium laser engraving machines and unlock incredible free gifts to elevate your projects. Buy a CO₂ laser and receive a FREE Water Chiller, Rotary Axis, and LightBurn software. Purchase a Fiber Laser and get a FREE Rotary Axis. Plus, score a special $130 OFF on bundle deals and 30% OFF laser engraving materials. Don’t wait — use code BESTMP10 at checkout and click here to shop now! Read More: How to Master Ceramic Laser Engraving: A Hobby Guide