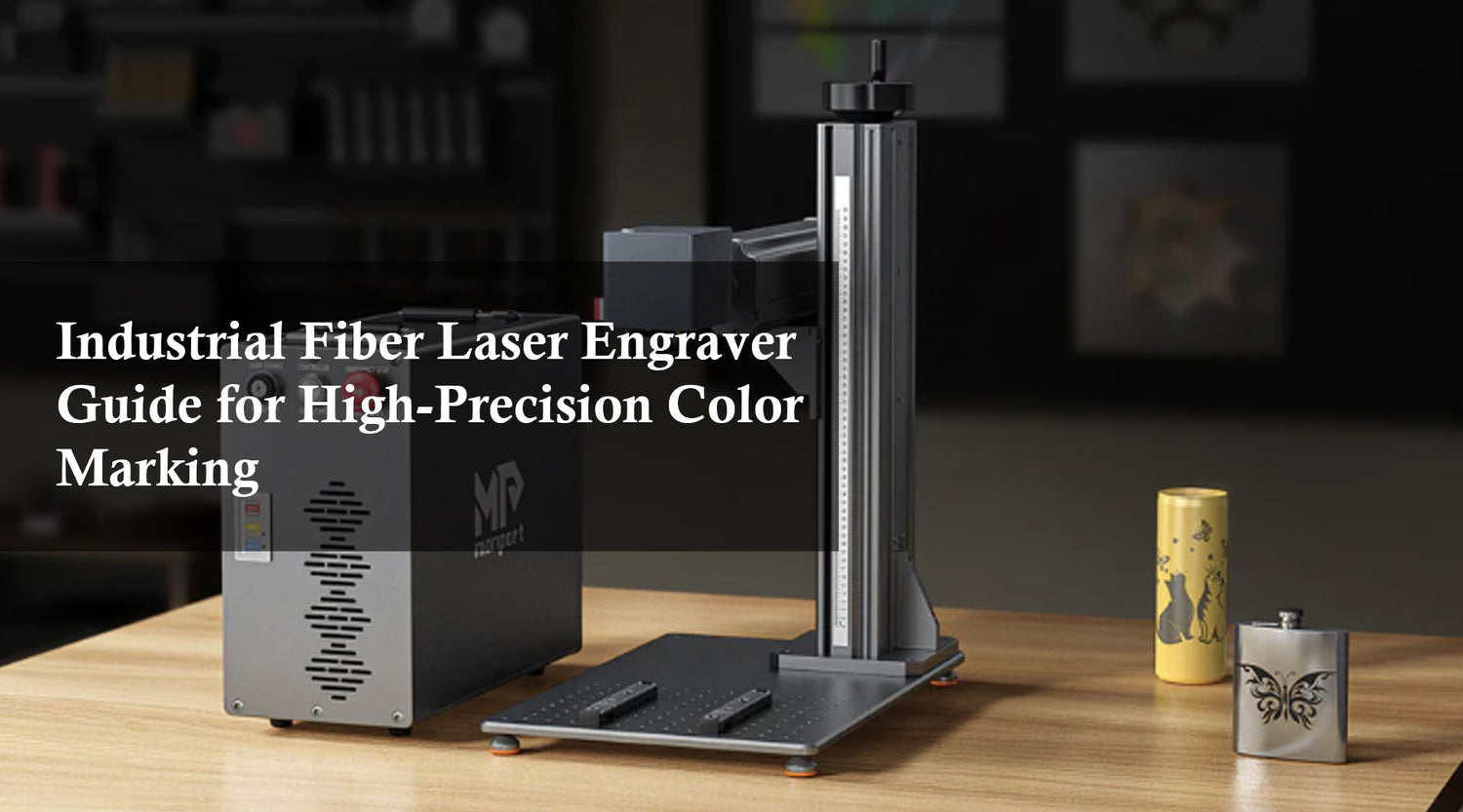

In the realm of precision engineering and craftsmanship, where every millimeter counts, the 50W fiber laser cutting technology stands as a beacon of innovation. At the forefront of this evolution is the Monport GQ 50W Fiber Laser Engraver & Marking Machine, a cutting-edge tool designed to redefine the standards of accuracy and efficiency. In this article, we delve into the intricacies of fiber laser cutting equipment, exploring its capabilities, applications, and the transformative impact it brings to various industries.

Unraveling the Technology: How 50W Fiber Laser Cutting Works

At the heart of fiber laser cutting lies advanced laser technology, where a high-powered laser beam is directed through fiber-optic cables onto the material surface, delivering unparalleled precision and speed. The Monport GQ 50W Fiber Laser Engraver & Marking Machine exemplifies this technology, boasting a power output of 50 watts, ideal for a diverse range of materials including metals, plastics, and composites. Below is a breakdown of its key specifications:

| Specification | Details |

|---|---|

| Laser Power | 50 Watts |

| Engraving Area | 7.9" x 7.9" |

| Approval | FDA Approved |

| Application | Engraving, Marking, Cutting |

FAQs: Navigating the Intricacies of Fiber Laser Cutting Equipment

1. What makes the Monport GQ 50W Fiber Laser Engraver stand out in the market?

The Monport GQ 50W Fiber Laser Engraver stands out due to its FDA approval, 7.9" x 7.9" engraving area, and robust 50W power output. It combines precision, speed, and versatility, making it suitable for industries like automotive, jewelry, and electronics manufacturing.

2. Can the 50W fiber laser cutting machine handle both delicate and heavy-duty projects?

Yes, the 50W fiber laser cutting machine is highly adaptable. It can manage delicate engravings on jewelry as well as heavy-duty tasks such as cutting and marking metals like stainless steel, brass, and aluminum.

3. How does fiber laser technology ensure precision and efficiency?

Fiber laser technology uses a concentrated laser beam transmitted through fiber-optic cables. This allows for minimal energy loss, faster processing speeds, and ultra-fine detailing, ensuring both precision and efficiency in every project.

4. Is the Monport GQ 50W suitable for small businesses and workshops?

Absolutely. Its user-friendly interface, compact design, and wide material compatibility make it perfect not only for large industrial facilities but also for small businesses and creative workshops.

5. What industries benefit the most from using a 50W fiber laser cutting machine?

Industries such as automotive, jewelry design, and electronics manufacturing benefit greatly. The machine’s ability to engrave, mark, and cut with extreme accuracy helps streamline production, maintain quality control, and foster innovation.

Exploring Applications: Where Precision Meets Versatility

The versatility of fiber laser cutting equipment knows no bounds, with applications spanning across a myriad of industries:

-

Automotive Industry: From precision cutting of automotive components to intricate engraving of serial numbers and logos, fiber laser cutting machines play a pivotal role in enhancing efficiency and quality control in automotive manufacturing processes.

-

Jewelry Design: Crafting intricate designs on precious metals requires the utmost precision, a feat easily achieved with a 50W fiber laser cutting machine. Jewelers can unleash their creativity, engraving intricate patterns, and customizing pieces with unparalleled accuracy.

-

Electronics Manufacturing: The demand for miniaturized electronic components necessitates cutting-edge technology. Fiber laser cutting equipment enables precise fabrication of circuit boards, ensuring optimal performance and reliability in electronic devices.

Important Details: Advantages of 50W Fiber Laser Cutting

-

High Precision: With a focused laser beam, the Monport GQ 50W Fiber Laser Engraver & Marking Machine delivers precise cuts and intricate engravings with minimal material wastage.

-

Speed and Efficiency: Equipped with advanced automation features and high-speed scanning systems, fiber laser cutting machines offer rapid processing, optimizing production workflows and reducing lead times.

-

Versatility: From thin foils to thick metals, fiber laser cutting equipment accommodates a wide range of materials, making it a versatile solution for diverse manufacturing needs.

Key Takeaways: Harnessing the Power of Fiber Laser Cutting

-

Enhanced Precision: Fiber laser cutting technology offers unparalleled accuracy, making it indispensable in industries where precision is paramount.

-

Streamlined Operations: By automating repetitive tasks and reducing setup times, fiber laser cutting machines streamline manufacturing processes, boosting productivity and efficiency.

-

Versatility and Adaptability: From small-scale workshops to large industrial facilities, the versatility of fiber laser cutting equipment makes it adaptable to a wide range of applications and industries.

Conclusion: Shaping the Future with Fiber Laser Cutting

In the ever-evolving landscape of manufacturing and design, fiber laser cutting equipment stands as a testament to innovation and precision engineering. The Monport GQ 50W Fiber Laser Engraver & Marking Machine exemplifies the transformative power of this technology, empowering industries to push the boundaries of creativity and efficiency. As we journey towards a future defined by precision and excellence, fiber laser cutting remains at the forefront, shaping the way we craft, design, and engineer the world around us.

Read More: Crafting Memorable Gifts with Your 50W Mini Laser Engraving Machine