Laser Engraving & Cutting Materials

Black Leather Laser Engraving: Your Guide to Exquisite Creations

Seeking the "best leather laser engraver"? Discover the magic of black leather engraving! Create personalized wallets, bags, phone cases & more with Monport Laser's exquisite designs & expert guidance for best settings engraving black leather fiber. Turn ordinary into extraordinary!

Read moreLaser Engraving & Cutting Materials

Raise Your Glass: Best 100W CO2 Laser for Glass Laser Engraving in Breweries & Businesses

Unlock your creativity & personalize glassware like a pro! The Monport 100W CO2 laser, perfect for breweries & businesses, boasts a spacious workbed, high-performance laser & advanced features. Create unique gifts, awards, promos & more! Boost your brand, impress customers. Visit our website & learn more!

Pawsome Pet Gear: Wood Engraving with Monport 100W Laser

Spoil your pet with pawsome accessories! Treat your furry best friend to unique, personalized wood engraving pet gear crafted with love using the Monport 100W laser engraving machine. From engraved collars & tags to cozy beds & treat jars, unleash your creativity & show your love with one-of-a-kind gifts.

Top 5 Ways of Wood Engraving with Monport's 100W Laser Machine

Explore the top 5 ways to do wood engraving, from traditional hand carving to the high-tech power of a 100W laser engraving machine. Discover the magic of Monport's 100W laser for unparalleled precision, versatility, and ease of use. Craft personalized masterpieces on wood, glass, acrylic, and more! Unleash your creativity - start laser wood engraving today!

Glass Laser Engraving & Etching FAQs: Master the Craft with Monport's 100W Laser

Unlock the magic of glass laser engraving! This comprehensive guide answers all your questions, from technique & design tips to using Monport's best 100W CO2 laser. Create personalized gifts, stunning home decor & more - the possibilities are endless! Start your glass laser engraving journey today.

Glass Laser Engraving: Etch Timeless Designs with Monport's Best 80w CO2 Laser

Master glass engraving with Monport's Best 80w CO2 Laser! Uncover features like auto-focus, air assist & safety sensors. Explore engraving gifts, home decor & art possibilities. Unleash your creativity & elevate your craft today!

Wood Engraving: Tips & Tricks with Your 80W Laser Engraving Machine

With these tips and tricks, you're well on your way to mastering the art of wood engraving with your 80w laser engraving machine. Remember, practice makes perfect, so experiment, explore, and don't be afraid to unleash your creativity. As your skills develop, you'll be amazed at the stunning and personalized wooden masterpieces you can create.

Monport's 80w CO2 Laser: The Ultimate Guide to Glass Engraving Excellence

Seeking to transform ordinary glass into breathtaking masterpieces? Monport's best 80w CO2 laser makes it a reality! This versatile machine unlocks the full potential of glass laser engraving, empowering you to etch intricate designs, personalized messages, and stunning artwork with unmatched precision and detail. Whether you're a seasoned artist or a curious beginner, Monport's 80w CO2 laser is your gateway to unleashing your creativity and exploring the endless possibilities of glass engraving.

Wood Engraving: Projects Made Possible with Monport 80w Laser Engraving Machine

Dive into the world of wood engraving with Monport's 80w laser powerhouse! Explore endless project ideas, from personalized gifts to stunning home decor & intricate crafts. Discover the power, precision & ease of use that sets Monport apart. Start creating & elevate your woodworking today!

Luxury on Demand: Laser Leather Engraving for Businesses & Makers

Elevate your brand & craft with laser-engraved leather! From wallets to home décor, Monport's fireproof laser engraver unlocks exquisite possibilities. Craft personalized leather gifts, elevate your brand, & explore endless designs with confidence. Safety, precision & artistry - all in one! Craft luxury on demand!

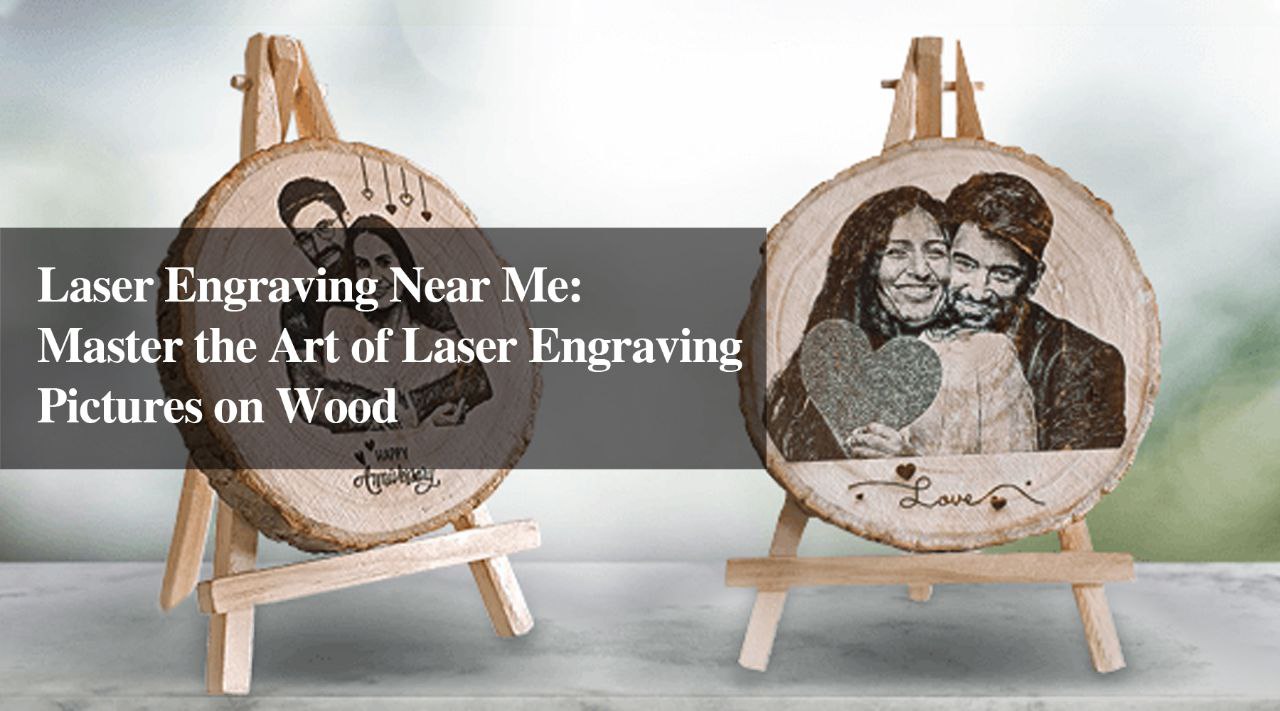

Laser Engraving Near Me: Master the Art of Laser Engraving Pictures on Wood

More than just a picture, it's a story in wood. Capture precious moments with laser engraving on wood by Monport Laser. Personalized gifts, home decor & awards that leave a lasting impression. Explore, design & bring your memories to life!

Pictorial Precision: Mastering Photo Laser Engraving with Monport's Best Laser Engraving Machine

Discover the art of photo laser engraving with the Monport 150W Built-in Chiller CO2 Laser Engraver & Cutter. This guide covers everything from selecting the right materials—like wood, metal, and glass—to step-by-step instructions for achieving stunning results. Learn how to prepare your photo, set up the machine, and create personalized keepsakes that stand the test of time.

Engraving Wood Near Me: Your Guide to Beautiful Personalized Creations with Laser Technology

Searching for "wood engraving near me"? Look no further! Discover the magic of laser engraving & cutting for personalized gifts, home decor & more. Find expert tips & partner with Monport Laser to create lasting memories!