In the realm of metal engraving, a new era of creativity has dawned with the advent of color laser engraving technology. Gone are the days of monochromatic designs etched onto metal surfaces; instead, vibrant hues and intricate details now grace the very fabric of metal, thanks to the remarkable capabilities of color laser engraving on metal. With each pulse of light from a fiber laser engraver for metal, a world of possibilities unfolds, inviting us to explore the boundless potential of color engraving metal.

Laser etching on metal is now more advanced than ever, offering durable, precise, and colorful finishes. Join us on a journey as we delve into the mesmerizing realm of color, light, and innovation in metal engraving with MOPA fiber laser technology.

Learn about color laser engraving technology

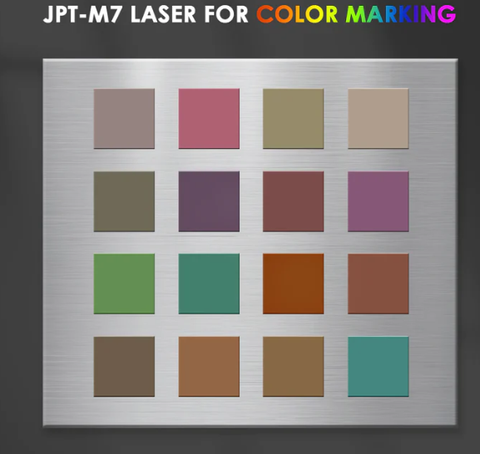

Color enbgraving technology utilizes high-powered lasers, such as MOPA fiber lasers, to etch intricate designs and patterns onto metal surfaces. Unlike traditional color engraving methods, this innovative approach offers the ability to create vibrant and multi-colored designs with extreme precision and accuracy. This is achieved by modulating the laser pulses to control depth, spacing, and intensity—resulting in stunning visual effects on stainless steel and other compatible metals. Laser etching on metal enhances these results by combining durability with artistry.

Choose the right full-color marking machine

When selecting a full-color marking machine for metal engraving, it's crucial to understand how laser engraving color works. Machines like the Monport 60W MOPA fiber laser offer adjustable pulse frequency and width, which are essential for vivid and customizable color marking on stainless steel. For artists and businesses alike, this unlocks endless creative potential for laser engraving color patterns, logos, barcodes, and artwork with high contrast and permanence. These benefits make laser etching on metal a top choice for both professionals and hobbyists.

Monport GI60 Integrated MOPA Fiber Laser Engraver & Marking Machine with Electric Lifting

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

Unique features of MOPA 60W fiber laser:

Full-color marking: Monport’s 60W JPT MOPA fiber laser engraving machine achieves bright and colorful full-color marking on stainless steel with its adjustable pulse frequency and width. In addition, it boasts over 100,000 hours of MTTF, with an accuracy of 0.05 mm per cut and an accuracy of up to ±0.1 micron.

New integrated innovative design: The machine has been enhanced with light weight, small footprint, stylish design and user experience while maintaining the same performance.

Electric Lifting Focus: Monport integrates a hidden electric lifting motor to ensure precise focusing, smooth operation, and significantly improve the marking effect. Designed specifically for beginners, this feature makes precision engraving a breeze.

Fully Compatible with LightBurn: Monport’s fiber metallic laser engraving machines come with free EZCad 2.0 software and are fully compatible with LightBurn software, providing a seamless marking experience, user-friendly controls and extensive customization options.

Industry-leading cooling technology: The machine has a built-in air cooling system and unique side panel perforations to ensure better heat dissipation and maintain the best performance of the machine.

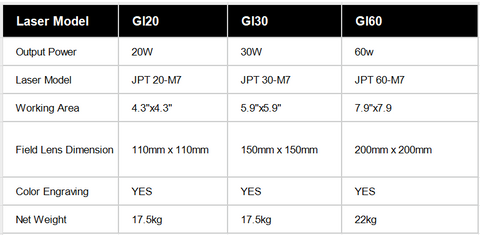

In addition to the 60W MOPA color engraving machine, Monport also offers 20W and 30W models. You can learn the difference between them in the following table:

FAQs

1. What is color laser engraving on metal?

Color laser engraving on metal is a process that uses advanced MOPA fiber laser technology to create vibrant, multi-colored designs on metal surfaces. By adjusting laser pulse frequency, width, and other parameters, you can achieve precise and vivid color effects, especially on stainless steel and other compatible metals.

2. Which metals are best for color laser engraving?

Stainless steel is the most popular choice for color laser engraving because it produces vivid and durable color results. Other suitable materials include titanium, aluminum alloys, and certain coated metals. The results may vary depending on the metal’s composition and surface finish.

3. What makes the Monport 60W MOPA fiber laser ideal for color engraving?

The Monport 60W MOPA fiber laser offers adjustable pulse frequency and width, allowing for bright and customizable full-color marking. It also features an integrated electric lifting system for easy focusing, compatibility with LightBurn software, and industry-leading cooling technology for consistent performance.

4. Do I need special software for color laser engraving?

Most MOPA fiber laser machines, including Monport models, come with EZCad 2.0 software and are compatible with LightBurn for more advanced design work. These programs allow you to create, edit, and adjust your designs to achieve the best possible engraving results.

5. Are there safety precautions I should take during color laser engraving?

Yes. Always wear safety goggles to protect your eyes from laser exposure, use gloves when handling metal pieces, ensure your workspace is well-ventilated, and follow the manufacturer’s operating instructions. Testing your settings before engraving the final piece is also highly recommended. Proper safety ensures high-quality laser etching on metal without risks.

Important Details to Consider When color laser engraving on metal

Material Selection: Choose metal materials suitable for color engraving, such as stainless steel, aluminum alloys, etc.

Surface Preparation: Ensure the metal surface is smooth and clean to achieve optimal engraving results.

Engraving Parameter Settings: Adjust the parameters of the metallic laser engraving machine, including power, speed, frequency, etc., according to the specific metal material and desired engraving effect.

Design Preparation: Prepare the design patterns to be engraved and make necessary adjustments and optimizations using engraving software.

Safety Precautions: Wear appropriate personal protective equipment, such as safety goggles and gloves, to ensure safe operation.

Testing and Adjustment: Conduct test engravings to confirm the accuracy of parameter settings before proceeding with the actual engraving, and make adjustments as needed.

Environmental Control: Ensure good ventilation in the working environment during color laser engraving to avoid dust and foreign particles in the engraving area.

Post-Processing: After completing the engraving, perform proper post-processing such as cleaning and polishing to enhance the quality and appearance of the engraving.

As you embrace the power of MOPA fiber laser technology, remember that laser engraving color opens a whole new dimension of personalization and professional-grade metal artistry. From industrial barcodes to luxurious full-color branding, the possibilities are endless. Laser etching on metal remains one of the most reliable and versatile applications of this technology.

So, embrace the future of metal engraving with color laser technology and MOPA fiber laser, and let your imagination soar as you embark on a journey of creativity, innovation, and boundless possibilities. Unlock the brilliance of color laser engraving on metal with Monport, and redefine what's possible in the world of metallic laser decoration and customization.

Read More: Beginners Guide To The K40 Laser Engraver - Monport