Introduction

Laser engraving aluminum is a versatile and precise technique that allows you to create intricate designs, markings, and patterns on aluminum surfaces. Whether you’re a hobbyist, small business owner, or industrial manufacturer, understanding how to use a laser engraver aluminum machine is key to achieving high-quality results. This guide covers everything from preparation to machine settings for flawless aluminum engraving.

Introduction to Laser Engraving Aluminum

Laser engraving uses a focused laser beam to remove or alter material on the surface of an object, leaving a permanent mark. Aluminum is an ideal material for laser engraving because of its:

-

Durability and corrosion resistance

-

Lightweight properties

-

Widespread industrial and creative applications

While traditional engraving removes material, aluminum laser etching modifies the surface through oxidation, producing high-contrast, detailed results. For deeper and long-lasting marks, a fiber-based laser engraver aluminum machine delivers the best precision and durability.

Preparing Aluminum for Laser Engraving

Proper preparation ensures optimal results:

-

Surface Cleaning: Remove dust, oil, and debris

-

Surface Coating: Apply laser marking spray or masking tape for higher contrast

-

Test Samples: Conduct small trial engravings to fine-tune settings

These steps enhance the clarity of laser etched aluminum and improve the overall quality of your engravings.

Choosing the Right Laser Engraving Machine

The right equipment is essential for successful aluminum engraving:

-

Laser Type: Fiber lasers are ideal for direct aluminum engraving; CO₂ lasers work for coated surfaces

-

Power & Wattage: Higher wattage enables faster, deeper engravings

-

Precision: Look for machines with high-resolution output for intricate designs

Monport GI60 Fiber Laser Engaver for Optimal Aluminum Engraving

The Monport GI60 60W Integrated MOPA Fiber Laser Engraver excels in both aluminum engraving and laser etching. Its MOPA technology delivers sharp contrast and clean results for aluminum surfaces.

Read More : The Ultimate Guide to Laser Engraving Aluminum with a Metal Laser Engraver Machine

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

Precision Engineering for Superior Results

At the heart of the Monport GI60 lies a state-of-the-art fiber laser system meticulously engineered for precision and performance. Here's a closer look at what sets the GI60 apart:

-

Fiber Laser Technology: Equipped with a high-powered fiber laser source, the GI60 delivers exceptional beam quality and stability, ensuring crisp, clear, and precise engravings on aluminum surfaces.

-

High-Speed Engraving: With rapid scanning and engraving speeds, the GI60 accelerates production workflows, enabling users to achieve faster turnaround times without compromising on quality.

-

Dynamic Focusing System: Automatically adjusts in real-time, ensuring uniform engraving aluminium results across varying material thicknesses.

Unrivaled Versatility and Flexibility

From intricate designs to industrial-grade markings, the Monport GI60 offers unparalleled versatility and flexibility in aluminum engraving applications:

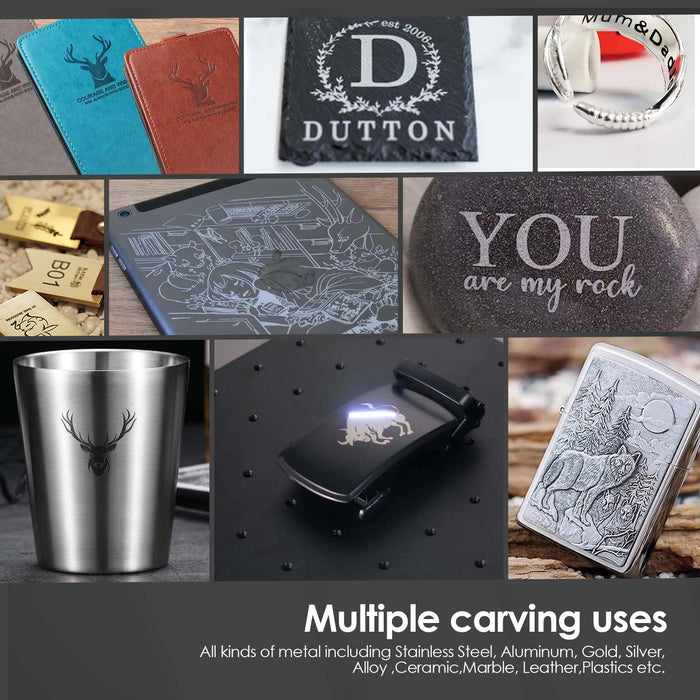

- Wide Range of Materials: In addition to aluminum, the GI60 can engrave a variety of other metals, including stainless steel, brass, copper, and more, making it suitable for a diverse range of projects and applications.

- Variable Marking Depths: With customizable laser settings, users have full control over the depth and intensity of the engraving, allowing for precise adjustment based on material type, thickness, and desired outcome.

- Advanced Software Integration: The GI60 seamlessly integrates with industry-leading engraving software, providing intuitive control over engraving parameters, design workflows, and automation capabilities, streamlining the engraving process from start to finish.

Enhanced Productivity and Efficiency

In today's fast-paced manufacturing environment, efficiency is key. The Monport GI60 Laser Metal Engraver is designed to maximize productivity and minimize downtime, empowering users to optimize their workflows and achieve peak efficiency.

- Batch Processing: With advanced batch processing features, users can engrave multiple aluminum parts simultaneously, reducing overall production time and increasing throughput.

- Remote Monitoring and Control: The GI60 offers remote monitoring and control capabilities, allowing users to oversee the engraving process from anywhere, anytime, via a user-friendly interface accessible from desktop computers, laptops, or mobile devices.

- Predictive Maintenance: Leveraging predictive maintenance algorithms, the GI60 proactively identifies and addresses potential issues before they escalate, minimizing unplanned downtime and maximizing uptime for uninterrupted production.

Seamless Integration into Existing Workflows

Whether you're a seasoned engraving professional or a newcomer to the world of laser engraving, the Monport GI60 seamlessly integrates into existing workflows, offering a user-friendly experience from setup to operation:

- Plug-and-Play Installation: The GI60 features a plug-and-play design, making setup quick and hassle-free, with minimal technical expertise required.

- Intuitive User Interface: Equipped with an intuitive touchscreen interface, the GI60 provides easy access to essential engraving functions, settings, and controls, ensuring a seamless user experience for operators of all skill levels.

- Comprehensive Training and Support: Monport offers comprehensive training and support resources, including user manuals, tutorials, and technical assistance, empowering users to harness the full potential of the GI60 and achieve optimal results in aluminum engraving.

Watch this video to learn more about the Monport GI60 Fiber Laser

Overall, the Monport GI60 Fiber Laser Metal Engraver represents the pinnacle of precision, versatility, and efficiency in aluminum engraving. Engineered with state-of-the-art technology and user-centric design principles, the GI60 empowers users to unlock new levels of creativity, productivity, and profitability in their engraving endeavors.

Optimizing Laser Engraving Settings

Fine-tuning the laser engraving settings is essential for achieving desired results:

- Speed and Power: Experiment with different speed and power settings to find the optimal balance between engraving depth and speed. Lower power settings are suitable for shallow engravings, while higher power settings are ideal for deeper marks.

- Frequency and Pulse Rate: Adjust the laser frequency and pulse rate to control the intensity and density of the engraved marks. Higher frequencies and pulse rates result in smoother engraving lines and finer details.

- Dithering and Halftoning: Utilize dithering and halftoning techniques to simulate grayscale images and achieve varying shades of gray on the aluminum surface. This is particularly useful for creating photorealistic engravings and intricate designs.

Safety Precautions

Laser engraving aluminum involves potential hazards, so it's essential to prioritize safety:

- Protective Gear: Wear appropriate safety goggles to shield your eyes from the laser beam and prevent potential injuries.

- Ventilation: Ensure proper ventilation in the workspace to dissipate fumes and smoke generated during the engraving process.

- Fire Safety: Keep a fire extinguisher nearby and be vigilant of any flammable materials that may ignite during the engraving process.

Post-Processing and Finishing

Once the engraving is complete, consider the following post-processing steps to enhance the final appearance:

- Cleaning: Remove any residue or debris from the engraved surface using a soft brush or compressed air. For stubborn stains, gently wipe the surface with a damp cloth.

- Surface Treatment: Apply a protective coating or clear lacquer to the engraved aluminum surface to prevent oxidation and preserve the design for long-term durability.

- Polishing: If desired, polish the engraved aluminum surface to achieve a glossy finish and enhance the visibility of the design.

Applications of Aluminum Laser Engraving

Aluminum laser engraving is widely used across industries:

-

Product identification and aluminum engraving plates

-

Laser engraving aluminum control panels

-

Decorative aluminum engraving signage

-

Laser aluminum engraving for electronics housings

Laser etching on aluminum ensures long-term readability even in harsh environments.

Unlock Flawless Metal Marking with Monport Black Laser Marking Spray

When it comes to creating professional-grade metal engravings, Monport black laser marking spray is a must-have for makers, hobbyists, and professionals alike. This powerful aerosol spray is specially formulated to work with CO2 laser machines of 25 watts and above, producing permanent black markings with exceptional contrast. Whether you're working on stainless steel, brass, or aluminum, the black laser marking spray bonds effortlessly to the surface, allowing for detailed and precise designs. Its fine-particle formula and anti-clog nozzle ensure smooth, even coverage every time. Drying in just five minutes, the black laser marking spray is easy to use and leaves no sticky residue after rinsing. From customizing jewelry to labeling tools or decorating metalware, the black laser marking spray from Monport delivers clean, bold results that last.

FAQs About Laser Engraving Aluminum

Can you laser engrave aluminum directly?

Yes, laser engrave aluminum directly using a fiber-based aluminum laser engraver.

What is the difference between laser etching and engraving on aluminum?

Laser etching on aluminum alters the surface, while aluminum laser engraving removes material.

Is aluminum laser engraving permanent?

Yes, aluminum engraving and aluminum laser etching are permanent.

What aluminum works best for laser marking?

Anodized aluminum produces the highest contrast laser marking aluminum results.

Conclusion

Laser engraving aluminum delivers precision, durability, and flexibility for industrial and creative needs. By choosing the right aluminum laser engraver, preparing materials properly, and optimizing laser etching aluminium settings, aluminum laser engraving projects can achieve consistent, professional outcomes.

Discover the limitless possibilities of laser etched aluminum with Monport Laser. Whether you're a seasoned professional or an aspiring enthusiast, our website offers a wealth of resources, insights, and cutting-edge technology to elevate your craft. Explore our range of fiber laser engravers, including the industry-leading GI60, engineered for precision, versatility, and efficiency. Dive into our comprehensive guides, tutorials, and case studies to unlock new techniques and applications in aluminum engraving. Connect with our team of experts for personalized guidance and support on your engraving journey. Visit the Monport Laser website today and unleash your creativity with the power of laser technology.