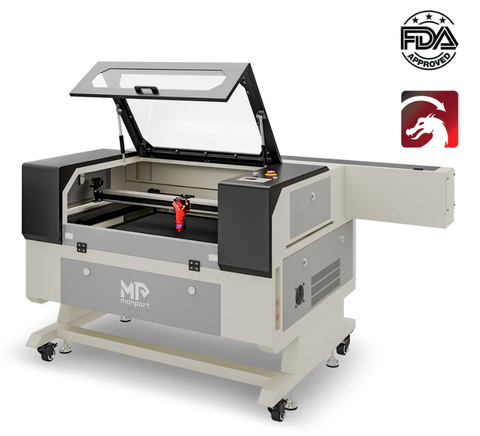

Unlock the precise and versatile world of how to cut acrylic sheet with a Monport CO2 laser engraving machine for sale! Acrylic sheets, known for their clarity, durability, and wide range of applications, are a popular choice for crafting, signage, and various creative projects. However, achieving clean and precise cuts on acrylic can be challenging with traditional tools.

This guide equips you with the knowledge and steps to master how to cut acrylic sheet with a laser cutter for acrylic sheet, specifically focusing on the powerful and user-friendly Monport CO2 laser systems and the use of black laser marking spray for enhanced contrast on certain materials.

Why Choose a Monport CO2 Laser Engraving Machine for Sale for Cutting Acrylic Sheet?

Monport CO2 laser cutter for acrylic sheet offers several advantages on how to cut acrylic sheet:

- Superior Precision: Achieve clean, professional-looking cuts with minimal to no burning edges, thanks to the focused laser beam and Monport's advanced technology.

- Versatility: Cut intricate designs, shapes, and letters with ease, offering endless possibilities for creative projects.

- Faster Cutting Speeds: Compared to traditional methods, laser cutting offers significantly faster turnaround times, boosting your productivity.

- Material Compatibility: Monport CO2 lasers are not limited to acrylic and can handle various materials like wood, leather, and fabric.

- Ease of Use: Monport's user-friendly interface and software make learning how to use a laser cutter for acrylic sheet smooth, allowing you to begin crafting projects quickly.

5 Steps How to Cut Acrylic Sheet with a Monport CO2 Laser:

Step 1: Gentle Reminder: Safety First!

Always prioritize safety when operating a laser engraving machine.

- Wear proper safety gear: This includes safety glasses, gloves, and appropriate clothing to protect yourself from dust and laser light exposure.

- Never leave the laser unattended: While the machine is operating, never leave it unattended and ensure proper ventilation is maintained.

- Follow operating instructions: Carefully read and follow the operating instructions and safety guidelines provided with your Monport CO2 laser engraving machine.

Step 2: Preparation

- Gather your materials: Ensure you have your acrylic sheet, Monport CO2 laser engraving machine, safety glasses, and a dust collection system.

- Design your project: Create your desired design using software compatible with your Monport laser, such as Lightburn or RDWorks.

- Prepare the acrylic sheet: Clean the surface to remove any dust or debris that might affect the cutting process.

Step 3: Machine Setup

- Import your design: Upload your design file to the laser engraving software and connect it to your Monport Laser engraving machine.

- Set cutting parameters: Based on the thickness of your acrylic sheet and desired results, adjust the laser power, cutting speed, and air assist settings. Refer to your Monport user manual or consult their technical support for specific recommendations.

- Place the acrylic sheet: Secure the acrylic sheet onto the laser bed, ensuring it's flat and level for precise cutting.

Step 4: Cutting Process

- Test cut: Before initiating the full cut, perform a test cut on a scrap piece of acrylic to fine-tune your settings and ensure optimal results.

- Start the cutting process: Once you're confident with your settings, initiate the cutting process using the laser engraving software's controls.

- Monitor the process: Observe the cutting process through the safety window, wearing designated safety glasses.

Step 5: Post-Processing

- Allow the acrylic sheet to cool: Once the cutting is complete, leave the acrylic sheet to cool down completely before handling it.

- Remove the cut pieces: Carefully remove the cut pieces from the acrylic sheet.

- Clean and finish (optional): Depending on your project, you might need to polish or sand the cut edges for a smoother finish.

Frequently Asked Question: How to Cut Acrylic Sheet?

Acrylic sheet, while versatile, requires specific cutting techniques to achieve clean and precise results. Laser cutting, especially with a laser cutter for acrylic sheet, remains one of the most efficient and accurate methods, especially for intricate designs and professional results.

For Thin Sheets (under ¼ inch):

- Scoring: This method uses a scoring tool or a sharp knife to create a deep scratch line on the acrylic. Once scored deeply enough, snapping the sheet along the line with gentle pressure will create a clean break.

For All Thicknesses:

-

Rotary Tools: Dremel tools with appropriate cutting bits can be used for straight cuts or intricate curves on thinner sheets. However, thicker sheets might require multiple passes and proper ventilation due to melting.

-

Jigsaws and Coping Saws: These hand-held saws, equipped with fine-tooth blades designed for plastics, can cut straight lines or gentle curves in acrylic sheets. Clamping the sheet securely for stability is crucial.

For Thicker Sheets (over ¼ inch):

-

Table Saws: Powerful table saws with fine-tooth blades specifically designed for acrylic cutting deliver clean and precise straight cuts. Ensure proper blade height adjustment and feed the sheet at a steady pace to avoid melting.

-

Laser Cutters: For intricate designs or mass production, laser cutters offer exceptional precision and minimal material waste. This method is ideal for professional applications or makerspaces with access to such equipment.

General Tips for Cutting Acrylic Sheet:

- Safety First: Wear safety glasses and gloves to protect yourself from flying debris and sharp edges.

- Sharp Blades: Ensure your cutting tools have sharp blades to minimize chipping and melting.

- Clamping: Secure the acrylic sheet firmly using clamps to prevent movement and ensure a clean cut.

- Slow and Steady: Avoid rushing the cutting process. Maintain a slow and controlled feed rate to achieve a clean cut.

- Ventilation: When using rotary tools or saws, ensure proper ventilation to remove dust particles and prevent acrylic from melting.

Remember: Choosing the right cutting method depends on the thickness of the acrylic sheet, the desired cut type (straight or curved), and your budget/equipment availability.

Unleash Your Creativity with a Monport CO2 Laser for Sale!

Monport CO2 laser engraving machine for sale offer a powerful and versatile solution on how to cut acrylic sheet and various other materials. With their user-friendly interface, advanced features, and diverse range of models, they cater to both beginners and experienced makers using tools like black laser marking spray for precise and high-contrast results.

Ready to take your creativity to the next level? Explore the wide range of Monport CO2 laser cutter for acrylic sheet models today and bring your designs to life!

Read More: Vibrant Designs: Laserable Acrylic Sheets and Colored Acrylic Sheets for Cutting