Have you ever been in the middle of an intricate engraving project and suddenly faced an unexpected halt due to a black laser marking spray "Water Error" code on your laser engraving machine? This issue can often be resolved by checking your laser engraver parts or replacing faulty laser replacement parts. This frustrating scenario is all too common and often stems from issues with the water flow sensor. In this article, we will explore the causes of these water flow sensor problems and provide effective solutions to get your machine back up and running smoothly with lbest laser marking.

Issue 1: Water leakage from the laser engraving machine

Solution: Locate the source of the leak. Seal it by reinstalling washers or using waterproof tape (e.g., plumber's tape) to secure the leaking hose. Ensuring the water system is intact is crucial, especially when using advanced systems like lbest laser marking machines.

Issue 2: Control Panel Displays "Water Error" Code

Step 1 . Check System Configuration:

These error codes relate to the water cooling system. Verify the setup and flow direction of the water cooling system. Inspect pipes and connections for leaks. Make sure the water outlet of the water pump/cooler is connected to the water inlet at the rear of the machine. This is essential for lbest laser marking to function properly.

Step 2 . Inspect Water Flow:

Check the water cooling system for adequate water flow. Disconnect the water pump/cooler outlet and check for proper water flow. Check the water hose for kinks. Correct any water flow problems or replace the laser engraver parts such as the water pump/cooler if necessary. Ensuring a steady flow is key for the best laser marking precision.

Step 3 . Sensor Installation:

Confirm the four bolts securing the flow sensors for water are facing upwards. Adjust the installation angle if needed. Proper sensor setup is especially important when using systems like lbest laser marking to avoid disruptions in the engraving process.

Step 4 . Sensor Testing:

Short-circuit the water flow sensor interface on the mainboard. If the error code disappears, the sensor may need replacement. If the water/cooler error persists, try the method for issue 3 following and contact Monport's support. Checking the sensor regularly is crucial for machines with laser engraver parts and laser replacement parts to ensure optimal black laser marking spray capabilities.

Issue 3: Persistence of Water/Cooler Error Despite Previous Steps

If you complete all four steps above and the water/cooler error code persists, the water flow sensor will need to be replaced. Please contact Monport for a replacement. In the meantime, you can bypass the water flow sensor using the laser software settings. Systems with laser engraver parts and laser replacement parts can be affected by this if not properly addressed.

Bypassing Water Flow Sensor in Software

For LIGHTBURN:

- Open LightBurn, click "Edit", "Machine Settings", double-click "Vendor Settings".

- Scroll down to "Enable Water Protection" under "Laser 1" and switch this setting to FALSE.

- Click "Save" to save changes. Test the laser to ensure it operates correctly.

For RDWORKS:

- Open RDWorks, click "File", "Vendor Settings", enter password RD8888.

- Navigate to the laser tab, find the waterproof protection option, and uncheck the corresponding box.

- Click "Save" to save changes. Test the laser to ensure it operates correctly.

-

Note:

- After disabling the flow sensors for water, if the water/cooler error code stops. It means that the water flow sensor needs to be replaced.

- If the water/cooler error persists after disabling the water flow sensor in your laser software.Your laser software may not be able to change the settings. Check your water settings again in LightBurn or RDWorks. If the error still displays, contact us for more information.

FAQs

1. What types of laser machines does Monport offer?

Monport provides a diverse range of laser machines, including:

-

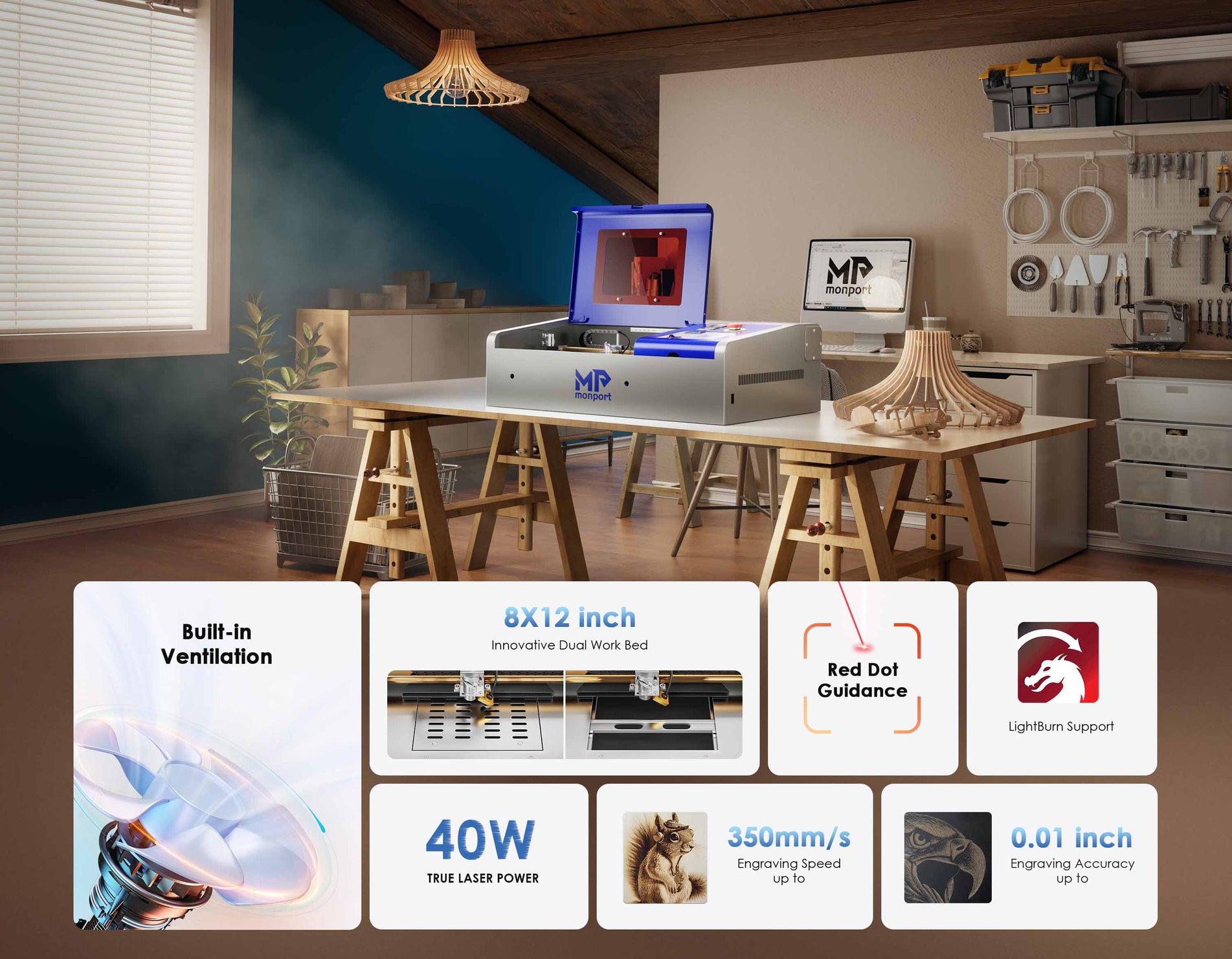

CO₂ Laser Engravers: Available in various power levels (e.g., 40W, 60W, 80W, 100W, 130W), suitable for materials like wood, acrylic, leather, and glass.

-

Fiber Laser Engravers: Designed for metal marking and engraving, ideal for industrial applications.

-

Desktop Models: Compact and beginner-friendly options like the 40W and 55W models, perfect for hobbyists and small businesses.

Each machine series caters to different user needs, from entry-level to professional-grade applications.

2. What materials can I engrave or cut with a Monport laser machine?

Monport laser machines are versatile and can work with a wide array of materials:

-

CO₂ Lasers: Suitable for cutting and engraving wood, acrylic, leather, fabric, glass, and certain plastics.

-

Fiber Lasers: Ideal for marking and engraving metals such as stainless steel, aluminum, brass, and copper.

The specific capabilities depend on the machine's power and type.

3. How do I choose between a 60W and an 80W CO₂ laser cutter?

The choice between a 60W and an 80W CO₂ laser cutter depends on your specific needs: (60w vs 80w Laser Cutter: The Ultimate FAQ Guide by Monport Laser)

-

60W Laser: Suitable for thinner materials and detailed engraving tasks.

-

80W Laser: Offers deeper cuts and faster processing speeds, making it better for thicker materials and higher-volume projects.

Consider the materials you plan to work with and the desired production speed when choosing between the two.

4. What software is compatible with Monport laser machines?

Monport laser machines are compatible with several popular design and control software options:

-

LightBurn: A widely used software for designing and controlling laser cutters and engravers.

-

RDWorks: Often used with CO₂ laser machines for creating and managing cutting paths.

These software options allow users to create intricate designs and control the laser's operations effectively.

5. Does Monport offer customer support and training resources?

Yes, Monport provides comprehensive customer support and resources:

-

Technical Support: Available to assist with machine setup, troubleshooting, and maintenance.

-

User Manuals and Guides: Detailed documentation to help users understand and operate their machines.

-

Tutorials and Blogs: Educational content covering various topics, from beginner guides to advanced techniques.

Conclusion

By following these steps, you can effectively troubleshoot and resolve water flow sensor issues in your laser engraving machine. For any unresolved problems or replacement needs involving laser engraver parts or laser replacement parts, do not hesitate to reach out to our support team for prompt black laser marking spray assistance.

Make your move today, visit Monport, and don’t forget to use BESTMP10 at checkout to claim your special offer. Your next best-selling product line could be just one laser cut away. Click here!