Laser engraving has revolutionized the jewelry industry, offering precision, customization, and efficiency that traditional methods cannot match. When it comes to laser engraving gold jewelry, jewelry engraving machineOptions, particularly fiber lasers, are the preferred choice due to their ability to produce detailed and permanent markings without damaging the precious metal, especially when combined with black laser marking spray. In this article, we will explore the benefits of fiber laser metal engraving on gold jewelry and why fiber laser technology is the best option for this purpose.

The Appeal of Laser Engraving on Gold Jewelry

Gold jewelry, whether it's a wedding band, a necklace, or a bracelet, often holds significant sentimental and financial value. Adding a personal touch through engraving enhances its uniqueness and value. Here’s why laser engraving with a jewelry engraving machine is an excellent choice for gold jewelry:

1. Precision and Detail

-

Fiber lasers produce a highly focused beam, allowing for intricate designs, fine details, and small text to be engraved with exceptional clarity. This precision is essential for maintaining the elegance of gold jewelry, making the jewelry engraving machine indispensable.

2. Permanent Markings

-

Unlike other methods that may fade or wear off over time, laser engravings created by a jewelry engraving machine are permanent. They withstand daily wear and tear, ensuring that the engravings remain legible and beautiful for the life of the jewelry.

3. Customization

-

Laser engraving allows for endless customization options. From initials, dates, and names to complex designs and logos, customers can personalize their jewelry using a jewelry engraving machine to reflect their individual style or commemorate special occasions.

4. Non-Contact Process

-

The non-contact nature of laser engraving means that there is no physical pressure applied to the jewelry. This is crucial for preserving the integrity and surface finish of delicate gold pieces. A jewelry engraving machine ensures these benefits are consistently achieved.

Why Fiber Lasers are Ideal for Gold Jewelry Engraving

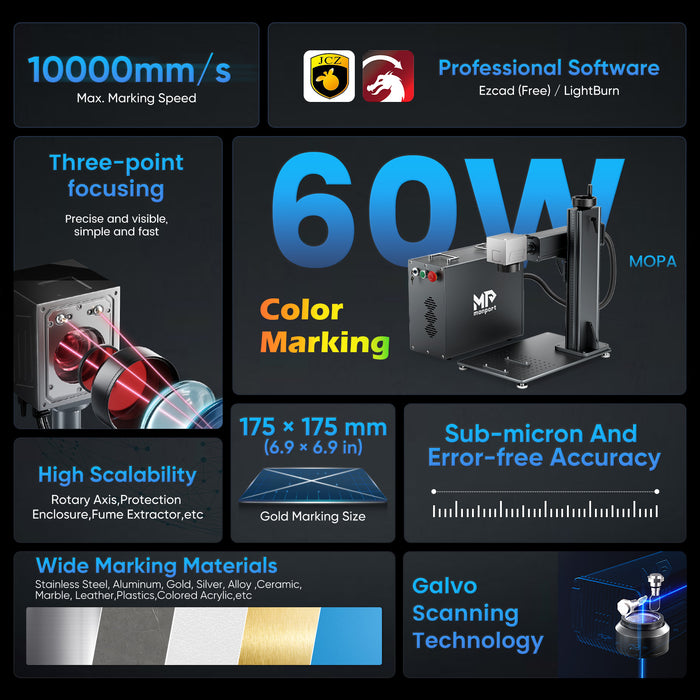

Monport GPro 60W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus - Machine

Fiber lasers are the gold standard for metal engraving due to their unique properties and capabilities. A jewelry engraving machine equipped with fiber laser technology offers the following advantages:

1. High Precision and Speed

- Fiber lasers can achieve extremely high precision, which is vital for detailed jewelry engravings. Additionally, they operate at high speeds, making the engraving process efficient and cost-effective.

2. Versatility

- Fiber lasers can engrave various types of metals, including gold, silver, platinum, and stainless steel. This versatility makes them a valuable tool for jewelers who work with different materials.

3. Durability and Longevity

- Fiber lasers have a long operational life and require minimal maintenance, making them a reliable investment for any jewelry business. Their durability ensures consistent performance over time.

4. Minimal Heat Generation

- Fiber lasers generate minimal heat during the engraving process, which prevents any warping or damage to the delicate gold surfaces. This is particularly important for maintaining the quality of fine jewelry.

5. Fine Beam Quality

- The fine beam quality of fiber lasers allows for high-resolution engravings. This is perfect for creating detailed and intricate designs on small jewelry pieces.

Fiber Laser Engraving Process for Gold Jewelry

The process of laser engraving gold jewelry using a fiber laser involves several steps:

-

Design Preparation

- The desired design or text is created using computer software. This design is then uploaded to the laser engraving machine’s control system.

-

Jewelry Positioning

- The gold jewelry piece is securely positioned on the engraving platform. Precision positioning is crucial to ensure that the engraving is applied accurately.

-

Parameter Settings

- The laser parameters, such as power, speed, and frequency, are adjusted according to the specific requirements of the gold piece. These settings ensure optimal engraving quality.

-

Engraving Process

- The fiber laser engraver starts the process, guided by the pre-loaded design. The laser beam precisely etches the design onto the gold surface, creating a permanent mark.

-

Finishing Touches

- After engraving, the jewelry piece may undergo additional finishing processes, such as polishing or cleaning, to enhance its appearance.

Popular Applications and Ideas

Laser engraving can transform gold jewelry into unique, personalized items. Here are some popular applications and ideas:

- Wedding Bands: Engrave names, dates, or special messages inside or outside the bands.

- Pendants: Personalize pendants with initials, meaningful symbols, or custom designs.

- Bracelets: Add inspirational quotes, dates, or patterns to gold bracelets.

- Rings: Create intricate designs or add personal touches to gold rings.

- Cufflinks: Engrave monograms or logos for a sophisticated and personal accessory.

FAQs About Laser Marking on Gold

Can you laser engrave any type of gold?

Yes. Yellow, white, and rose gold can all be engraved using a fiber laser.

Does laser engraving damage gold jewelry?

No. The process is non-contact and low-heat, making it safe for delicate metals.

How deep can a laser engrave on gold?

Depth depends on laser power and settings, but fiber lasers allow both surface marking and deep engraving.

Is gold laser engraving permanent?

Yes. Laser-engraved marks remain sharp indefinitely with regular wear.

What is the best machine for laser engraving gold jewelry?

A fiber laser engraver for jewelry provides the highest precision and quality.

Conclusion

Fiber laser engraving is a powerful technique for customizing gold jewelry, offering unparalleled precision, durability, and versatility. For jewelers and hobbyists alike, investing in a fiber laser engraving machine can open up a world of creative possibilities and elevate the quality of their work. Whether you’re personalizing a special piece for a customer or creating intricate designs, fiber lasers provide the tools needed to achieve stunning results on gold jewelry.