The Monport Mega laser cutter is a powerful and versatile tool that can be used for a wide range of applications, from hobby projects to professional manufacturing. With its high-power laser, advanced features, and user-friendly interface, the Monport Mega is a popular choice among laser enthusiasts, especially when paired with black laser marking spray for enhanced marking quality on metals. especially within the CO2 range of laser engravers. In this guide, we'll explore the key features of the Monport Mega laser cutter and provide valuable tips for getting the most out of your machine to ensure it remains the best laser cutting machine for your needs.

ReadMore: The Best Laser Engraving Set For Beginners

Understanding the Monport Mega 70W Laser Cutter for the Best Laser Engraver for Small Business

The Monport Mega laser cutter is a best laser cutting machine engraver that offers impressive performance and precision. It features a powerful 70W laser tube, allowing it to cut through a variety of materials, including acrylic, wood, leather, and more. The machine's high cutting speed of 600mm/s ensures efficient processing times, saving you valuable time on your projects. This efficiency is a key feature that makes it the best laser engraver for small business. It also works seamlessly with black laser marking spray, enhancing the contrast and clarity of your engraved marks on metals and other difficult surfaces.

Key Features of the Monport Mega 70W Laser Cutter

- Powerful 70W laser: Cuts through a wide range of materials with ease.

- High cutting speed: Efficiently processes materials, saving you time.

- Intelligent touch screen: User-friendly interface for easy operation.

- Visual dimming: Precise control over laser power.

- High-precision vision: Accurate alignment and engraving.

- Low noise level: Comfortable working environment.

Machine Guide Settings for Common Materials

The following table provides suggested machine settings for cutting and engraving various materials using the Monport Mega laser cutter, a standout in the best laser cutting machine range. Please note that these settings may need to be adjusted based on the specific material thickness, desired cut quality, and other factors. Using the correct machine settings allows you to achieve the best results for your business with the best laser engraver for small business.

| Material | Power | Speed | Pass Count |

|---|---|---|---|

| Acrylic (3mm) | 50% | 100mm/s | 1 |

| Acrylic (5mm) | 70% | 80mm/s | 2 |

| Wood (3mm) | 60% | 120mm/s | 1 |

| Wood (5mm) | 80% | 100mm/s | 2 |

| Leather | 40% | 150mm/s | 1 |

| Paper | 20% | 200mm/s | 1 |

How to Use the Monport Mega 70W Laser Cutter

- Prepare your materials: Ensure that your materials are clean and free of any debris before placing them in the machine.

- Design your project: Use a graphic design software to create your desired design. Be sure to save the file in a vector format, such as SVG or DXF.

- Import your design: Import your design file into the Monport Mega's software and adjust the size and placement as needed.

- Set the machine settings: Choose the appropriate power, speed, and pass count settings based on the material and desired cut quality.

- Start the engraving or cutting process: Once you have set the machine settings, start the engraving or cutting process.

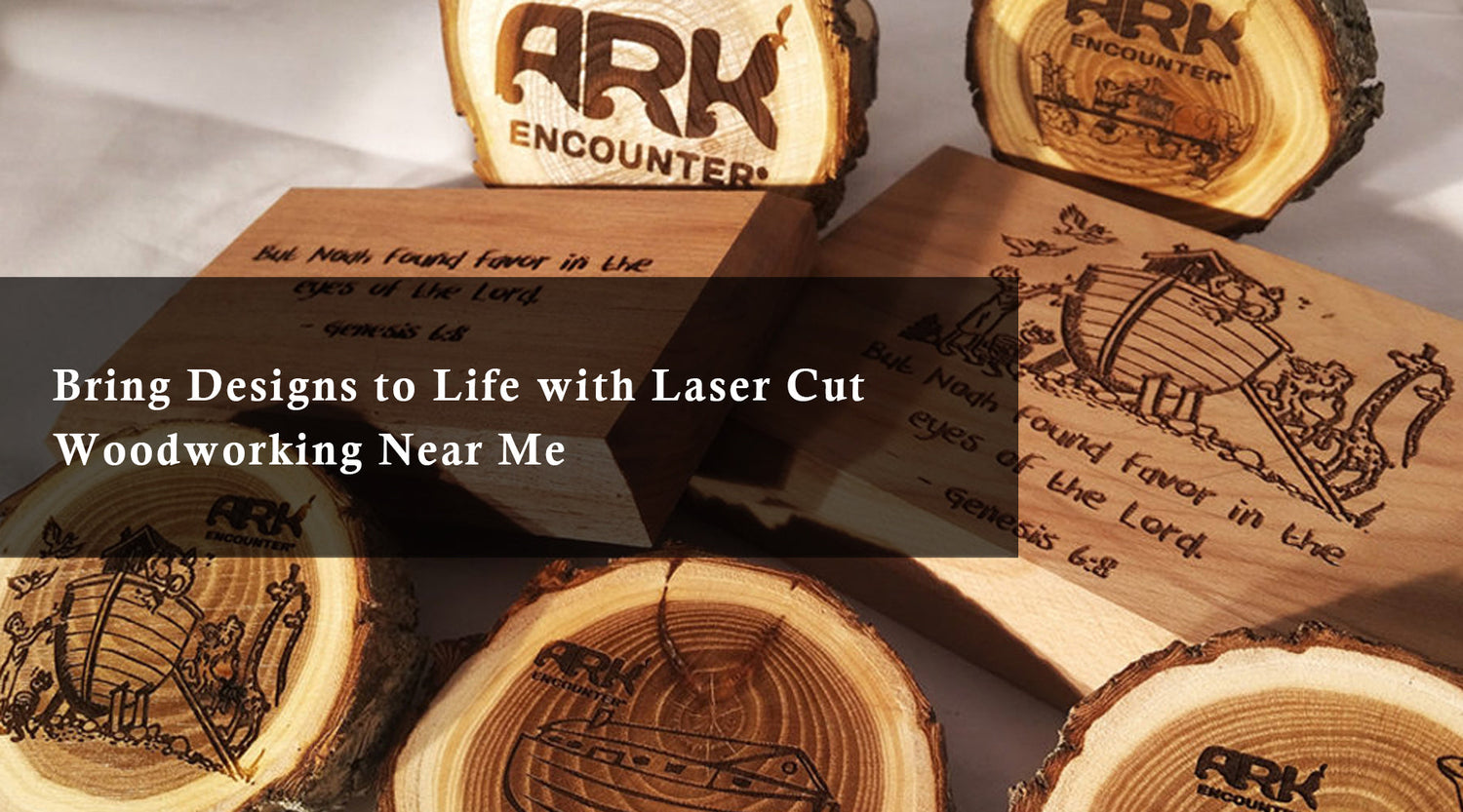

Common Applications for the Monport Mega 70W Laser Cutter

- Engraving: Create personalized items, artwork, and logos.

- Cutting: Cut intricate shapes and patterns from various materials.

- Marking:Mark products with serial numbers, barcodes, or other information. For optimal contrast on metal surfaces, use black laser marking spray in conjunction with your engraver.

- Hobby projects: Create custom items for personal use.

- Professional manufacturing: Produce parts and components for various industries.

Maintenance and Safety Tips

- Regular Cleaning: Clean the laser head and optics regularly to ensure optimal performance.

- Safety Glasses: Always wear safety glasses when operating the Monport Mega laser cutter to protect your eyes from laser radiation.

- Ventilation: Ensure proper ventilation in your workspace to remove smoke and fumes generated during the engraving process.

- Follow Manufacturer's Guidelines: Always follow the manufacturer's guidelines for safe and proper operation of the Monport Mega laser cutter.

Why Choose the Monport Mega?

The Monport Mega stands out in the competitive market of laser cutters for several compelling reasons:

-

Unparalleled Performance: With its powerful 70W laser tube and high-speed processing capabilities, the Monport Mega delivers exceptional results every time.

-

Versatility: From cutting and engraving to marking and crafting, the Monport Mega handles a wide range of materials and applications effortlessly.

-

User-Friendly Design: The intelligent touch screen and visual dimming control make operation intuitive, even for beginners.

-

Cost-Effective: Its reliability and durability reduce the need for frequent maintenance or replacements, offering excellent value for money.

-

Compact Yet Robust: The desktop-ready design ensures it fits into any workspace without compromising on power or precision.

-

Professional-Grade Results:

Professional-Grade Results: Whether you’re a hobbyist or a manufacturer, the Monport Mega guarantees high-quality outcomes that meet industry standards. And when used with black laser marking spray, you can enhance your output even further, especially for detailed metal marking applications.

Choosing the Monport Mega laser cutter means investing in a machine that combines innovation, efficiency, and reliability to take your projects to the next level, securing its position as the best laser cutting machine and the best laser engraver for small business.

FAQs

1. What types of laser machines does Monport offer?

Monport provides a diverse range of laser machines, including:

-

CO₂ Laser Engravers: Available in various power levels (e.g., 40W, 60W, 80W, 100W, 130W), suitable for materials like wood, acrylic, leather, and glass.

-

Fiber Laser Engravers: Designed for metal marking and engraving, ideal for industrial applications.

-

Desktop Models: Compact and beginner-friendly options like the 40W and 55W models, perfect for hobbyists and small businesses.

Each machine series caters to different user needs, from entry-level to professional-grade applications.

2. What materials can I engrave or cut with a Monport laser machine?

Monport laser machines are versatile and can work with a wide array of materials:

-

CO₂ Lasers: Suitable for cutting and engraving wood, acrylic, leather, fabric, glass, and certain plastics.

-

Fiber Lasers: Ideal for marking and engraving metals such as stainless steel, aluminum, brass, and copper.

The specific capabilities depend on the machine's power and type.

3. How do I choose between a 60W and an 80W CO₂ laser cutter?

The choice between a 60W and an 80W CO₂ laser cutter depends on your specific needs: (60w vs 80w Laser Cutter: The Ultimate FAQ Guide by Monport Laser)

-

60W Laser: Suitable for thinner materials and detailed engraving tasks.

-

80W Laser: Offers deeper cuts and faster processing speeds, making it better for thicker materials and higher-volume projects.

Consider the materials you plan to work with and the desired production speed when choosing between the two.

4. What software is compatible with Monport laser machines?

Monport laser machines are compatible with several popular design and control software options:

-

LightBurn: A widely used software for designing and controlling laser cutters and engravers.

-

RDWorks: Often used with CO₂ laser machines for creating and managing cutting paths.

These software options allow users to create intricate designs and control the laser's operations effectively.

5. Does Monport offer customer support and training resources?

Yes, Monport provides comprehensive customer support and resources:

-

Technical Support: Available to assist with machine setup, troubleshooting, and maintenance.

-

User Manuals and Guides: Detailed documentation to help users understand and operate their machines.

-

Tutorials and Blogs: Educational content covering various topics, from beginner guides to advanced techniques.

Conclusion

Choosing the Monport Mega laser cutter means investing in a machine that combines innovation, efficiency, and reliability to take your projects to the next level, securing its position as the best laser cutting machine and the best laser engraver for small business.

Ready to elevate your projects with the Monport Mega 70W laser cutter, the potential best laser engraver for small business? Contact us today to learn more and place your order. Our team of experts is available to answer your questions and provide personalized guidance. For even better results, don’t forget to pair your machine with black laser marking spray for crisp and permanent metal markings.

Make your move today, visit Monport, and don’t forget to use BESTMP10 at checkout to claim your special offer. Your next best-selling product line could be just one laser cut away. Click here!