Leather cutting is an intricate craft that requires precision, skill, and the right tools. In recent years, laser engraver cutter technology has emerged as a game-changer in the world of leather crafting, offering unmatched accuracy and efficiency. Whether you're a seasoned artisan or a beginner enthusiast, mastering the art of laser cut leather with laser engraving equipment opens up a world of creative possibilities. In this guide, we'll walk you through the process step by step, helping you unlock the full potential of your laser cutter for cutting leather with laser cutter projects.

Step 1: Preparation

Before diving into the cutting process, it's essential to properly prepare your leather and laser engraver cutter equipment. Start by selecting high-quality leather suitable for laser cutting. Ensure that the surface is clean and free from any debris or imperfections that could affect the cutting process.

Calibrate your laser engraving equipment based on your leather's thickness and texture. Adjust the laser power, speed, and frequency to achieve your desired cutting depth and edge smoothness. Always perform test cuts on scrap leather before starting your main project to fine-tune your settings for the best results in cutting leather with laser cutter machines.

Step 2: Design and Layout

Once your equipment is calibrated, it's time to create or import your design into the laser engraver cutter software. Whether you're cutting intricate patterns, precise shapes, or custom designs, the software allows you to visualize and adjust your layout with precision.

Consider the thickness and grain direction of your leather. Arrange your design on the software’s workbed to minimize waste and ensure optimal alignment for cutting leather with laser cutter setups.

Step 3: Cutting Process

With your design finalized and the laser engraving equipment ready to go, it's time to initiate the cutting process. Place your prepared leather material onto the workbed of the laser cutter, ensuring it is securely positioned and flat to avoid any movement during cutting.

The laser beam will trace your design with pinpoint precision. Thanks to modern cutting leather with laser cutter technology, you’ll achieve clean edges and consistent results, whether you're working on simple shapes or complex filigree.

Step 4: Post-Cutting Finishing

With your design finalized and the laser engraver cutter equipment ready to go, it's time to initiate the cutting process. Place your prepared leather material onto the workbed of the laser cutter, ensuring it is securely positioned and flat to avoid any movement during cutting.

Activate the laser engraver cutter and monitor the process closely. The laser beam will follow the contours of your design with pinpoint accuracy, resulting in clean, precise cuts. Depending on the complexity of your design and the thickness of the leather, cutting leather with laser cutter machines may take varying amounts of time.

Step 5: Clean-Up and Maintenance

After completing your leather cutting project, it's essential to clean and maintain your laser engraving equipment for optimal performance and longevity. Remove any debris or residue from the workbed and laser components using a soft brush or compressed air.

Routine maintenance of your laser engraver cutter not only ensures consistent results but also helps extend the machine’s lifespan—an important consideration when working frequently on cutting leather with laser cutter systems.

Unleash Your Creativity: The Monport 80W CO2 Laser Engraver

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

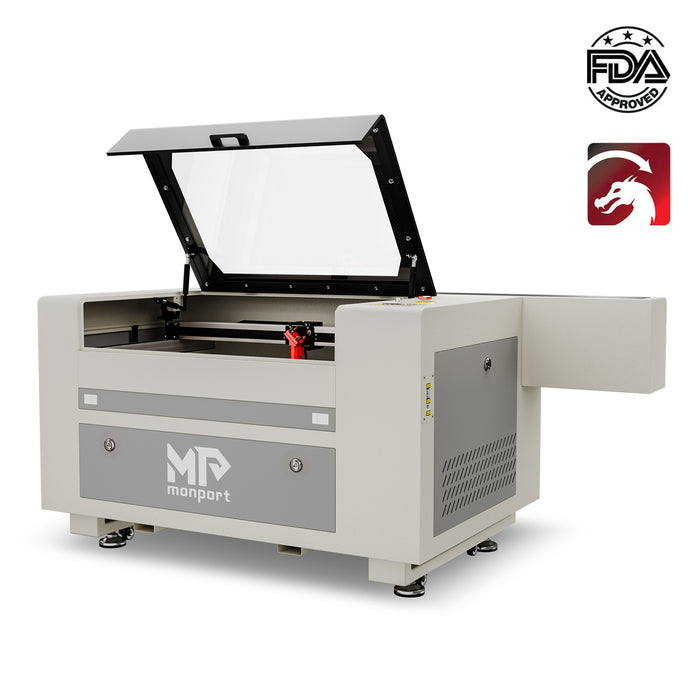

Leather crafting is an art form that demands precision and finesse. From intricate designs to bespoke patterns, every detail matters. To elevate your leather projects to new heights, you need a laser engraving equipment that combines power, precision, and versatility. Introducing the Monport 80W CO2 Laser Engraver – your ultimate companion for laser-cut leather creations.

Designed for Larger Engraving Projects

Craftsmanship knows no bounds, and neither should your equipment. The Monport 80W CO2 Laser Engraver features a spacious 16*24’’ work bed, providing ample space for large-scale projects. Its four-way pass-through capability allows for seamless engraving of items extending beyond the workbed, ensuring no project is too grand. With a high-quality metal honeycomb board and aluminum panel, this engraving tool offers double protection, keeping your work pieces secure and stable. Plus, its movable design accommodates thicker materials, guaranteeing versatility without compromise.

Great Compatibility, Endless Possibilities

Versatility is the hallmark of excellence, and the Monport 80W CO2 Laser Engraver delivers. Compatible with both Windows and Mac operating systems and supporting RDWorks and LightBurn software, this machine empowers users with precise control over a myriad of nonmetallic surfaces. From wood to glass, acrylic to leather, unleash your creativity with depths of up to 0.59'' and speeds of up to 800mm/s. Whether for DIY enthusiasts or commercial artisans, the possibilities are limitless.

High-Performance Laser Beam

At the heart of the Monport 80W CO2 Laser Engraver lies a high-performance laser beam, the result of joint research and development between Monport and Yongli. With up to 12,000 hours of operation, this laser cutter delivers an outstanding 6.5% higher actual RP compared to competitors with identical laser tube specifications. Experience unparalleled precision and efficiency with every engraving.

Intelligent Control Panel

Simplicity meets sophistication with the Monport 80W CO2 Laser Engraver's intelligent control panel. Driven by the Ruisin KT332N motherboard, this machine offers direct control over auto-focusing, Z-axis movement, and air assistance. Dynamic display of processing trajectory and progress enables users to modify layer parameters with ease, while power-off resume and accurate work time preview streamline the engraving process to perfection.

Advanced 4-in-1 Laser Head

Innovation takes center stage with the Monport 80W CO2 Laser Engraver's advanced 4-in-1 laser head. Combining laser emission, autofocus, air assist, and red light indication into a single unit, this machine redefines efficiency. With high-specification focusing lenses from wavelength optoelectronics, enjoy an unprecedented carving and cutting experience, revolutionizing your leather crafting endeavors.

Comprehensive Safety Features

Your safety is our priority. The Monport 80W CO2 Laser Engraver boasts comprehensive safety features, including an emergency stop button for rapid power shutdown, independent laser control with a dedicated key, and cover protection to halt operation when opened. Additionally, auto-stop functionality ensures peace of mind in the face of low water or high temperature conditions. With a fireproof window for observation and built-in ventilation for instant smoke removal, focus on your craft with confidence.

FAQs

Can you cut leather with a laser cutter?

Yes, laser cutting leather is effective for natural leather, producing clean edges with minimal finishing.

What leather works best for a laser cutter on leather?

Natural leather responds best when cutting leather with a laser, offering consistent and controlled results.

Is cutting leather with a laser safe?

Cutting leather with a laser is safe when proper ventilation and machine safety features are used.

Can a laser cutter leather machine engrave and cut?

Yes, a laser leather cutter can engrave details and cut shapes in one workflow.

Enhance Your Metal Engraving with Monport Black Laser Marking Spray

Monport black laser marking spray offers a reliable and easy-to-use solution for creating high-contrast, permanent marks on various metals. Compatible with CO2 laser engraving machines, this black laser marking spray provides an excellent finish on materials like aluminum, stainless steel, and brass. With its advanced formula, the spray ensures even coverage and deep penetration into the surface, producing durable marks that are resistant to heat and wear. The black laser marking spray dries quickly, allowing you to complete your projects efficiently. After engraving, simply rinse off the spray to reveal sharp, crisp markings. Monport’s black laser marking spray is the perfect tool for personalizing products, customizing metal items, and creating high-quality industrial markings with ease.

Read More : How to Clean Laser Engraved Leather: Mastering Custom Leather Laser Engraving

Conclusion

Laser cutting leather combines precision, efficiency, and creative freedom. By learning how to cut leather with a laser and maintaining a proper workflow, makers can achieve consistent, professional results. Whether producing detailed designs or large batches, a laser cutter on leather empowers artisans to elevate their craft with accuracy and control.

Cutting leather with laser engraving equipment opens up endless possibilities for creativity and craftsmanship. By following these steps and mastering the art of laser cutting, you can create stunning leather creations with unparalleled precision and efficiency. Whether you're crafting intricate designs, precise shapes, or custom projects, laser cutting technology empowers you to bring your visions to life with precision and finesse.