A high-quality trophy engraving equipment is essential for producing professional-grade awards. Traditional engraving methods can be time-consuming, labor-intensive, and prone to errors. Laser engraving, on the other hand, offers a fast, efficient, and precise solution. By investing in advanced trophy engraving machine, you can increase your production capacity, improve accuracy, and expand your design capabilities. Using a desktop CO2 laser can further streamline this process by enhancing precision and reducing production time.

In this blog post, we'll explore the benefits of laser cut trophy and how a high-powered desktop CO2 laser engraver like the Monport 80W CO2 laser engraver and cutting machine can help you achieve exceptional results.

Monport 80W Built-in Chiller CO2 Laser Engraver & Cutter (36" x 24")

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

ReadMore : Creating Stunning Trophies and Awards with Laser Engraving

The Importance of Trophy Engraving Equipment

A reliable and efficient trophy engraving equipment is essential for any business looking to produce high-quality trophies. Laser engraving offers several advantages over traditional methods, including the use of a desktop CO2 laser, which can provide:

- Precision: Laser engraving delivers incredibly detailed and accurate results, ensuring that every trophy looks its best.

- Versatility: From wood, acrylic, metal, and glass to various other materials, laser engraving can be used on a wide range of trophy substrates. With a desktop CO2 laser, this versatility is maximized.

- Speed: Desktop CO2 laser engraving is a fast process, allowing you to produce trophies efficiently and meet tight deadlines.

- Customization: With laser engraving, you can create personalized laser cut trophy with intricate designs and text, making each piece unique.

Laser Cut Trophy: A New Dimension in Design

Laser cutting technology opens up new possibilities for trophy design. By using a desktop CO2 laser cutter, you can create intricate shapes, patterns, and even three-dimensional elements for your trophies. This allows you to offer a wider range of designs to your customers and stand out from the competition.

Combining laser cutting with laser engraving creates truly exceptional trophies. You can laser cut the trophy base or create decorative elements with your desktop CO2 laser, and then add personalized engravings to complete the piece. This approach allows for endless customization options and visually stunning results.

Monport 80w CO2 Laser Engraver: Your Trophy-Making Partner

The Monport 80w desktop CO2 laser engraver is a powerful and versatile trophy engraving equipment ideal for engraving and cutting. Its advanced features and high-quality performance make it an excellent choice for businesses of all sizes.

Key features of the Monport 80w CO2 laser engraver:

- Built-in Smart Water Chiller: Protects the machine and enhances performance.

- Fireproof Viewing Window: Ensures safety during the engraving process.

- Enclosed Aeronautical Aluminum Rail: Provides precision and durability.

- Laser Protective Glasses: Protects your eyes from harmful radiation.

- Ruida Digital Controller: Offers compatibility with popular design software.

- High Speed and Resolution: Delivers detailed and efficient engravings.

- Autofocus: Simplifies the setup process.

- Built-in Air Assist: Improves engraving quality by removing debris.

- 3-ways to Connect with PC End: Provides flexibility for different setups.

- Red Dot Guidance: Assists with accurate placement of designs.

- Automatic Safety Sensor: Ensures safe operation.

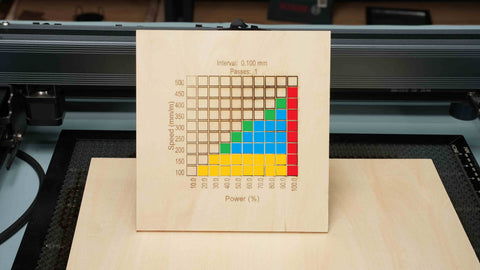

Machine Guide Settings for Wood and Acrylic Laser Cut Trophy

To achieve optimal results with laser cut trophy using wood and acrylic with your Monport 80w trophy engraving equipment understanding and adjusting machine settings is crucial. This section will provide essential guidelines to help you fine-tune your laser engraver for different materials and trophy designs.

Machine Guide Settings for Wood

Wood is a popular material for trophy bases and components. The following settings are a general starting point and may require adjustments based on wood type, thickness, and desired finish:

- Power: 60-80%

- Speed: 10-20 mm/s (for cutting), 30-50 mm/s (for engraving)

- Frequency: 20-30 kHz

- Air Assist: Medium to High

Tips:

- For intricate designs, reduce power and speed to prevent burning.

- Use a higher power and speed for thicker wood pieces.

- Experiment with different focus heights to achieve the desired cut quality.

Machine Guide Settings for Acrylic

Acrylic is another versatile material for trophy components, offering clarity and durability. Consider these settings as a starting point for your acrylic projects:

- Power: 30-50%

- Speed: 15-25 mm/s (for cutting), 30-40 mm/s (for engraving)

- Frequency: 20-30 kHz

- Air Assist: High

Tips:

- To minimize melting and discoloration, use a lower power setting.

- For clean cuts, ensure proper focus and air assist.

- Experiment with different engraving depths to create various effects.

Additional Tips for Trophy Creation

- Material Thickness: Adjust power and speed according to the thickness of the material. Thicker materials require higher power and slower speeds.

- Design Complexity: Intricate designs may require lower power and speed to prevent burning or melting.

- Test Cuts: Always perform test cuts on scrap material to fine-tune settings before working on your final piece.

- Ventilation: Ensure proper ventilation to remove smoke and fumes during the laser cutting process.

- Safety Gear: Wear protective gear, including laser safety glasses, gloves, and a dust mask.

Tips for Creating Exceptional Trophies

To create trophy masterpieces, consider the following tips:

- Choose the right materials: Select materials that complement your trophy design and meet your customers' expectations.

- Design with purpose: Create trophy designs that reflect the occasion or achievement being honored.

- Pay attention to detail: Ensure that all engravings and cuts are clean and precise.

- Experiment with different techniques: Combine laser engraving and cutting for unique effects.

-

Offer customization options: Allow customers to personalize their trophies.

Frequently Asked Questions About Trophy Laser Systems

1. What is the main advantage of using a trophy laser?

A trophy laser delivers precise, repeatable results while reducing production time compared to manual engraving methods.

2. Can one trophy engraving machine handle both trophies and medals?

Yes, a properly configured trophy engraving machine can function as a medals engraving machine for multiple award types.

3. Which materials work best for laser cut trophy projects?

Wood and acrylic are commonly used due to their clean cutting results and consistent engraving performance.

4. Is laser cut awards production suitable for small businesses?

Laser cut awards production scales easily, making it suitable for both small shops and growing operations.

Enhance Your Metal Engraving with Monport Black Laser Marking Spray

Monport black laser marking spray offers a reliable and easy-to-use solution for creating high-contrast, permanent marks on various metals. Compatible with CO2 laser engraving machines, this black laser marking spray provides an excellent finish on materials like aluminum, stainless steel, and brass. With its advanced formula, the spray ensures even coverage and deep penetration into the surface, producing durable marks that are resistant to heat and wear. The black laser marking spray dries quickly, allowing you to complete your projects efficiently. After engraving, simply rinse off the spray to reveal sharp, crisp markings. Monport’s black laser marking spray is the perfect tool for personalizing products, customizing metal items, and creating high-quality industrial markings with ease.

Conclusion

Investing in a high-quality trophy engraving equipment like the Monport 80w CO2 laser engraver and cutting machine can significantly enhance your trophy business. By combining laser engraving and cutting techniques, you can create stunning and customized trophies that will impress your customers. Embrace the power of technology to elevate your business and stand out in the competitive trophy market. A desktop CO2 laser will be a key asset in achieving success.