Jewelry making is an intricate art that demands precision and attention to detail. In recent years, integrated fiber laser cutting machines have emerged as indispensable tools for jewelry designers and manufacturers, offering unparalleled accuracy and versatility. In this article, we'll explore the benefits of investing in a fiber laser cutting machine for jewelry making and provide guidance on purchasing the right jewel laser machine for your needs.

Read More: Laser Etching & Engraving Jewelry

The Advantages of Fiber Laser Cutting Machines

Jewelry making is an intricate art that demands precision and attention to detail. In recent years, integrated fiber laser cutting machines and jewel laser systems have emerged as indispensable tools for jewelry designers and manufacturers, offering unparalleled accuracy and versatility. In this article, we'll explore the benefits of investing in a fiber laser cutting machine for jewelry making and provide guidance on purchasing the right machine for your needs.

- Precision Cutting: Fiber lasers produce fine, precise cuts with minimal heat-affected zones, ensuring clean edges and intricate designs.

- Versatility: These machines can cut through a wide range of thicknesses and materials, making them ideal for creating various jewelry components, from delicate filigree to robust bands.

- Speed and Efficiency: Fiber lasers operate at high speeds, allowing for quick production of jewelry pieces and minimizing production time.

- Minimal Maintenance: Compared to other cutting methods, fiber laser machines require minimal maintenance and offer long-term reliability.

- Cost-Effectiveness: While the initial investment may be higher, fiber laser machines offer lower operating costs and higher efficiency in the long run.

Choosing the Right Fiber Laser Cutting Machine

When purchasing a fiber laser cutting machine for jewelry making, there are several factors to consider to ensure you select the right machine for your needs:

-

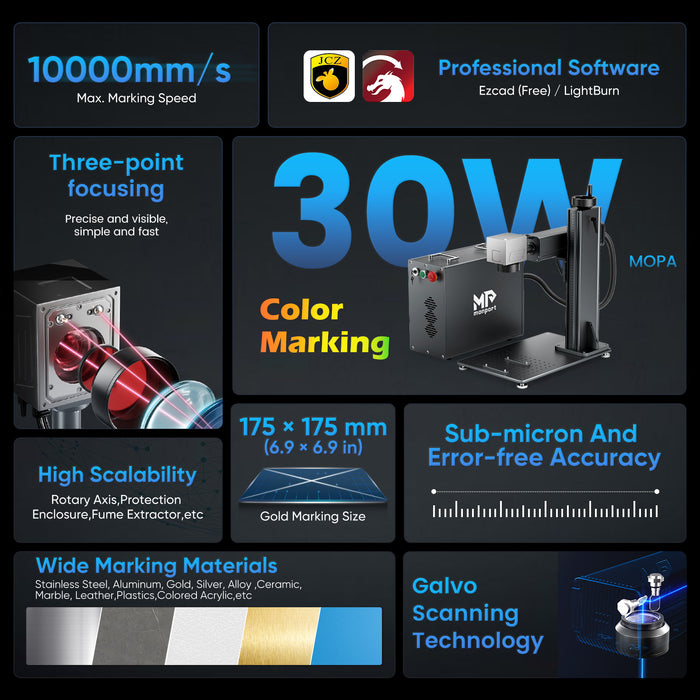

Power and Wattage

Consider the thickness and type of materials you'll be cutting to determine the appropriate laser power and wattage for your machine. The right jewel laser will provide the necessary strength without compromising detail. -

Cutting Area Size

Evaluate the size of your jewelry pieces and the workspace available to determine the optimal cutting area size for your machine. A compact jewel laser could be ideal for smaller studios. -

Precision and Accuracy

Look for machines with advanced features such as autofocus and high-resolution cutting heads to ensure precise and accurate cuts. A jewel laser ensures consistently flawless results. -

Software Compatibility

Ensure that the machine is compatible with industry-standard design software such as CAD/CAM programs for seamless integration into your workflow. Many jewel laser systems offer easy software integration. -

Reputation and Support

Choose a reputable manufacturer known for quality craftsmanship and reliable customer support to ensure a smooth purchasing and installation process. Monport is a leader in jewel laser technology with excellent support.

Conclusion: Elevate Your Jewelry Making with Monport Fiber Laser Cutting Machines

Investing in an integrated fiber laser cutting machine is a game-changer for jewelry designers and manufacturers, offering unmatched precision, versatility, and efficiency. With the right machine, you can take your jewelry production to new heights and create stunning pieces that stand out in the market.

Consider Monport fiber laser cutting machines and jewel laser solutions for your jewelry making needs. With their advanced technology, precise cutting capabilities, and dedicated customer support, Monport machines are the perfect choice for jewelry professionals looking to elevate their craft.

Ready to revolutionize your jewelry making process? Visit the Monport website today to explore their range of fiber laser cutting machines and take the first step towards precision and excellence in jewelry production.