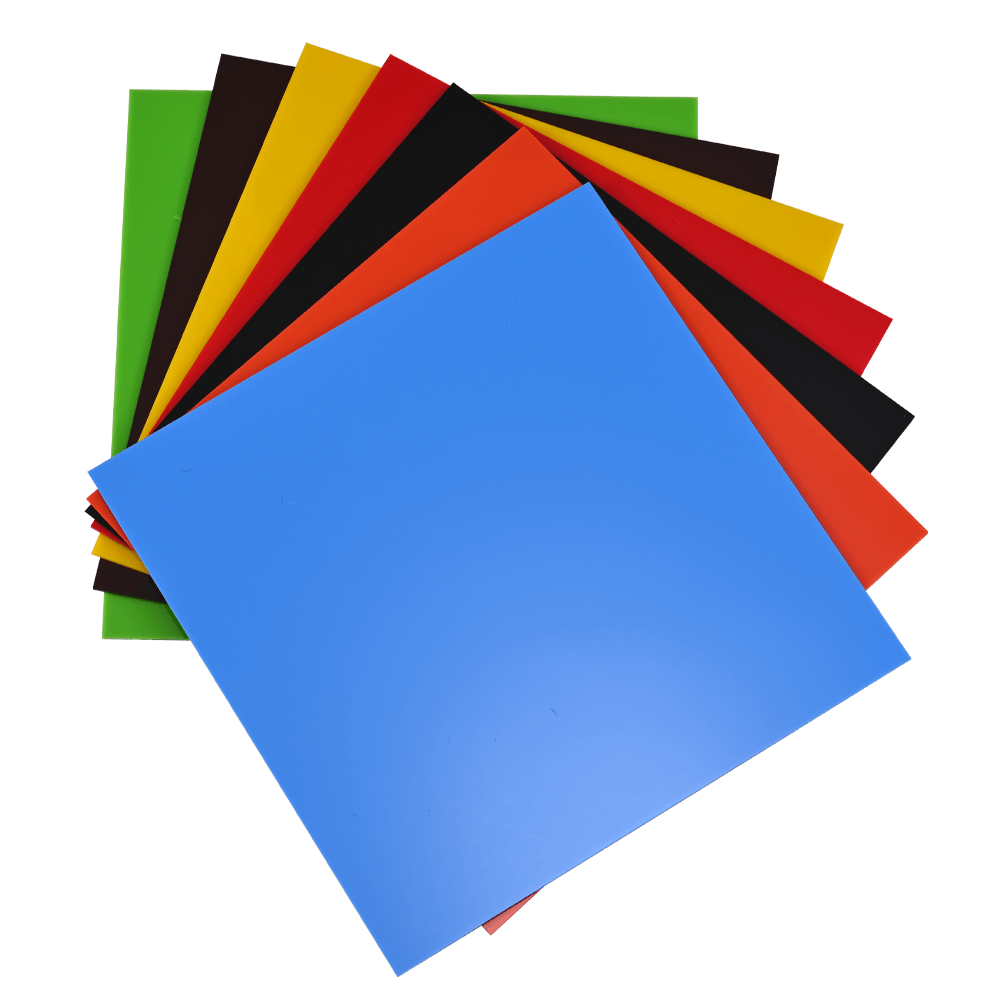

Mastering Laser Engraving: Monport's Best Machine for Acrylic

Introduction In the world of laser engraving, precision and quality matter. Monport stands out as a leader in the industry, offering the best laser engraving machine for working with laser engraving acrylic. This article explores the importance of choosing the...