Have you ever dreamt of adorning metal with a kaleidoscope of colors? Color laser etching, also known as laser engraving color, laser color engraving, and colored laser engraving, makes this dream a reality. This innovative technology transcends the limitations of traditional metal engraving, unlocking a world of vibrant and unique designs on laser etched metal surfaces.

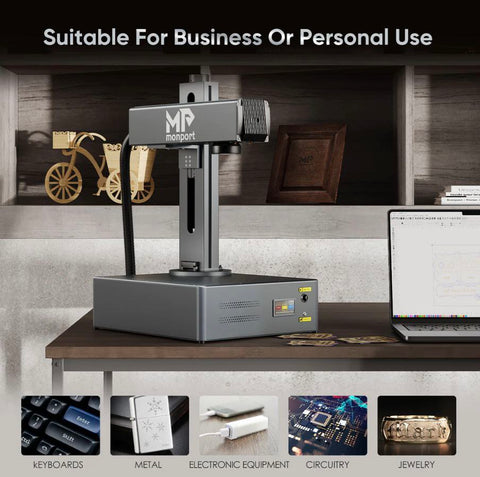

Monport Laser, a leader in the field of laser etcher technology, offers the state-of-the-art Monport GA Upgraded 30W Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus (30M7), perfectly suited for color laser etching, color laser marking on metal, and advanced laser coloring effects on laser etched metal. Whether you’re working on jewelry, industrial tags, or laser engraving steel projects like color-etched stainless steel plaques, this machine provides unmatched results for professional color engraving on metal.

What is Color Laser Etching?

Color laser etching metal, also known as colour laser engraving, laser engraving color, or laser color engraving, uses a high-powered laser to create permanent markings on laser etched metal. This method is commonly used for laser etching steel, stainless steel, titanium, and aluminum. For example, laser engraving steel with controlled laser parameters produces stable and vivid colored laser engraving results ideal for decorative and industrial use.

Unlike traditional engraving that removes material, color laser etching relies on surface interaction through:

-

Oxidation

The laser heats the laser etched metal, forming oxide layers that reflect light differently. Adjusting frequency and power allows precise laser coloring and controlled laser engraving color. -

Diffraction Grating

The laser forms microscopic patterns on the metal surface, bending light and creating multi-color effects. This is widely used in laser color engraving and artistic color engraving on metal.

This means you can laser etch metal not only with shapes or text but also with long-lasting colored laser engraving effects.

The Advantages of Color Laser Etching over Traditional Methods

Compared to sandblasting, paint filling, or acid etching, color laser etching and laser etching steel offer clear advantages:

-

Unmatched Vibrancy

Achieve consistent laser engraving color directly on laser etched metal without inks or coatings. -

Intricate Detail

Fine lines and micro-details are easy with laser etch metal systems, even on laser engraving steel. -

Durability

Color laser marking on metal is resistant to wear, heat, and chemicals. -

Versatility

Works on stainless steel, aluminum, titanium, and other metals suitable for laser coloring. -

Eco-Friendly

No chemicals, making color laser etching a cleaner solution.

Applications of Color Laser Etching Metal

Laser etched metal with colored laser engraving is used across many industries.

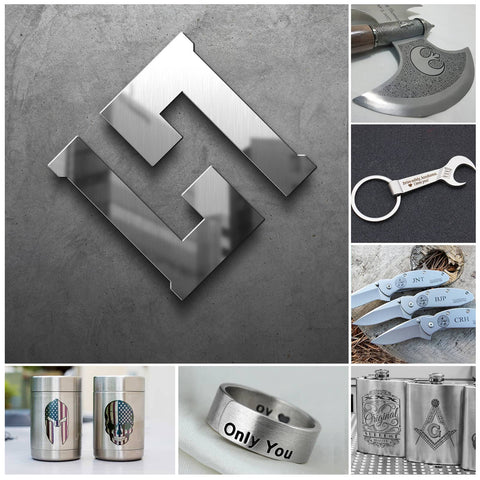

Personalized Jewelry and Accessories

Add branding and detail using laser engraving color and color engraving on metal for rings, pendants, and keychains.

Eye-Catching Signage and Plaques

Laser engraving steel combined with color laser marking on metal produces readable, long-lasting signage.

Artistic Expression

Artists rely on laser color engraving and laser coloring to transform flat sheets into vibrant works of art.

Industrial Applications

Serial numbers, QR codes, and labels benefit from laser etching steel and durable colored laser engraving.

A Laser Engraver's Guide to Color Laser Etching on Metal: Step-by-step process

The world of metalworking expands with laser etched metal and color laser etching. Below is the proven workflow.

1. Design Preparation

-

Use vector files for clean laser etch metal

-

Adjust line weight for accurate laser engraving color

-

Test settings to dial in laser coloring

2. Material Selection and Prep

Stainless steel is ideal for laser engraving steel and laser etching steel. Always clean surfaces before color laser etching to avoid uneven results.

3. Laser Setup and Calibration

MOPA lasers allow precise pulse control, which is critical for laser color engraving, laser coloring, and stable colored laser engraving.

4. The Etching Process

-

Monitor each pass carefully

-

Multiple passes can enhance color engraving on metal without damaging the surface

5. Post-Processing and Finishing

Clean residue gently and apply sealant if the laser etched metal will be exposed to harsh conditions.

The Monport GA Upgraded 30W Integrated MOPA Fiber Laser: Your Gateway to Color Laser Etching

The Monport GA 30M7 is engineered for advanced laser etched metal, laser engraving steel, and professional color laser etching workflows.

Key advantages include:

-

Auto-focus precision for consistent laser etching steel

-

Adjustable pulse width for advanced laser coloring

-

LightBurn compatibility for efficient laser engraving color

-

Stable output for repeatable colored laser engraving

This machine supports everything from small-scale laser color engraving to industrial color laser marking on metal.

FAQ: Color Laser Etching vs. Colored Fillings for Metal

1. Can I perform color laser etching on any metal?

Not all metals respond equally. Stainless steel and titanium are best for laser etching steel and laser engraving steel.

2. What’s the difference between color laser etching and colored resin fillings?

Color laser etching alters the laser etched metal itself, while resin fills can wear out over time.

3. Is this the same as anodizing metal?

No. Anodizing is chemical-based. Laser color engraving relies on laser interaction and laser coloring effects.

4. How do I get different colors with a MOPA laser engraver?

Color depends on pulse width, frequency, and speed. Testing is essential for consistent laser engraving color.

5. Do I need special software to design for color laser engraving?

LightBurn works well for laser etch metal, color engraving on metal, and laser engraving steel projects.

Conclusion

Color laser etching is more than engraving—it’s a powerful way to enhance laser etched metal with precision and creativity. From jewelry to industrial parts, colored laser engraving, laser coloring, and laser engraving steel elevate both appearance and durability.

If you're ready to expand your capabilities with reliable color laser marking on metal, Monport Laser provides the tools to do it right.

Don’t wait to elevate your metal engraving game. Use code BESTMP10 at checkout – click here to order your Monport GA 30W MOPA Fiber Laser Engraver today!