Can PU leather be laser engraved?The answer is yes, with some important considerations. The world of laser engraving offers endless possibilities for personalizing and creating unique items, especially when using a leather engraving laser designed for precision and control. Many beginners ask, can you laser engrave leather safely, and the short answer is yes, as long as you understand the material and follow proper safety steps. Additionally, when people wonder is PU leather safe for laser engraving, it can be engraved safely with proper ventilation and caution. This comprehensive guide explores the world of PU laser engraving for leather, covering feasibility, safety precautions, and essential tips to achieve stunning results using a Monport 40W CO2 Desktop Laser Engraver and a reliable leather engraving laser.

Monport 40W Lightburn-ready (12" X 8") CO2 Laser Engraver & Cutter with FDA Approval

Where Can You Get Leather Engraved Today?

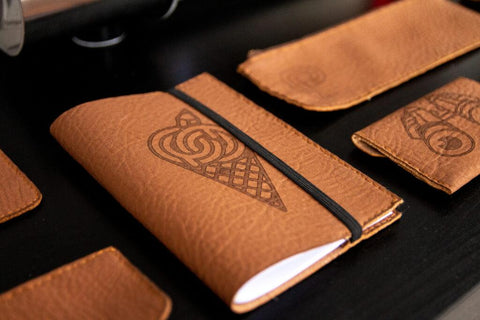

Where can you get leather engraved? Many creators and businesses now rely on personal laser engravers like the Monport 40W to handle laser etching on leather in-house, instead of outsourcing to third-party shops. With the right leather engraving laser, you can customize wallets, bags, keychains, and more whenever inspiration hits.

- Shop now and get 10% OFF with code BESTMP10 at checkout – click here to shop!

- Read More : How to Clean Laser Engraved Leather: Mastering Custom Leather Laser Engraving

Understanding PU Leather for Leather Laser Engraving

PU leather, also known as polyurethane leather, is a synthetic material designed to mimic the look and feel of genuine leather. It's popular for its affordability, durability, and versatility. However, its composition differs from natural leather, which affects how it reacts to laser etching on leather. When using a leather engraving laser, settings must be adjusted carefully to avoid melting or surface damage.

Laser Engraving PU Leather: What to Know

While PU leather can be engraved, many people still ask, can you laser engrave leather if it’s synthetic? Yes, but you must proceed carefully.

-

Fume Emission: During laser engraving, PU leather releases fumes that can be harmful. Proper ventilation is essential, especially when using a leather engraving laser in a small workspace.

-

Material Suitability: Not all PU leather behaves the same. Some types may melt or warp under heat, so testing is crucial before full laser etching on leather projects.

If you are still asking where can you get leather engraved, investing in a personal laser machine may be the most flexible option.

Safety First: Essential Precautions

Safety should always come first when working with PU leather. If you’re wondering is PU leather safe for laser engraving, the answer depends on following these precautions:

-

Ventilation: Always work in a well-ventilated area or use a fume extractor.

-

Respirator: Wear a respirator rated for organic vapors.

-

Eye Protection: Laser safety glasses are a must when operating any leather engraving laser.

For those who don’t own a machine yet and are still thinking about where can you get leather engraved, many makerspaces and libraries now offer public access to laser equipment.

Laser Engraving for Leather Tips for Success

Once safety is covered, here are practical tips to improve results when using a leather engraving laser on PU leather:

-

Lightburn Software: Lightburn works seamlessly with Monport machines, giving precise control for laser etching on leather.

-

Start with Low Power: Always begin at low power to avoid burning or melting.

-

Multiple Passes: Several light passes often produce cleaner results than one heavy pass.

-

Test and Adjust: Scrap testing is essential, especially if you’re new and still learning whether you can laser engrave leather consistently.

-

Cleaning: Wipe the surface gently after engraving to remove residue.

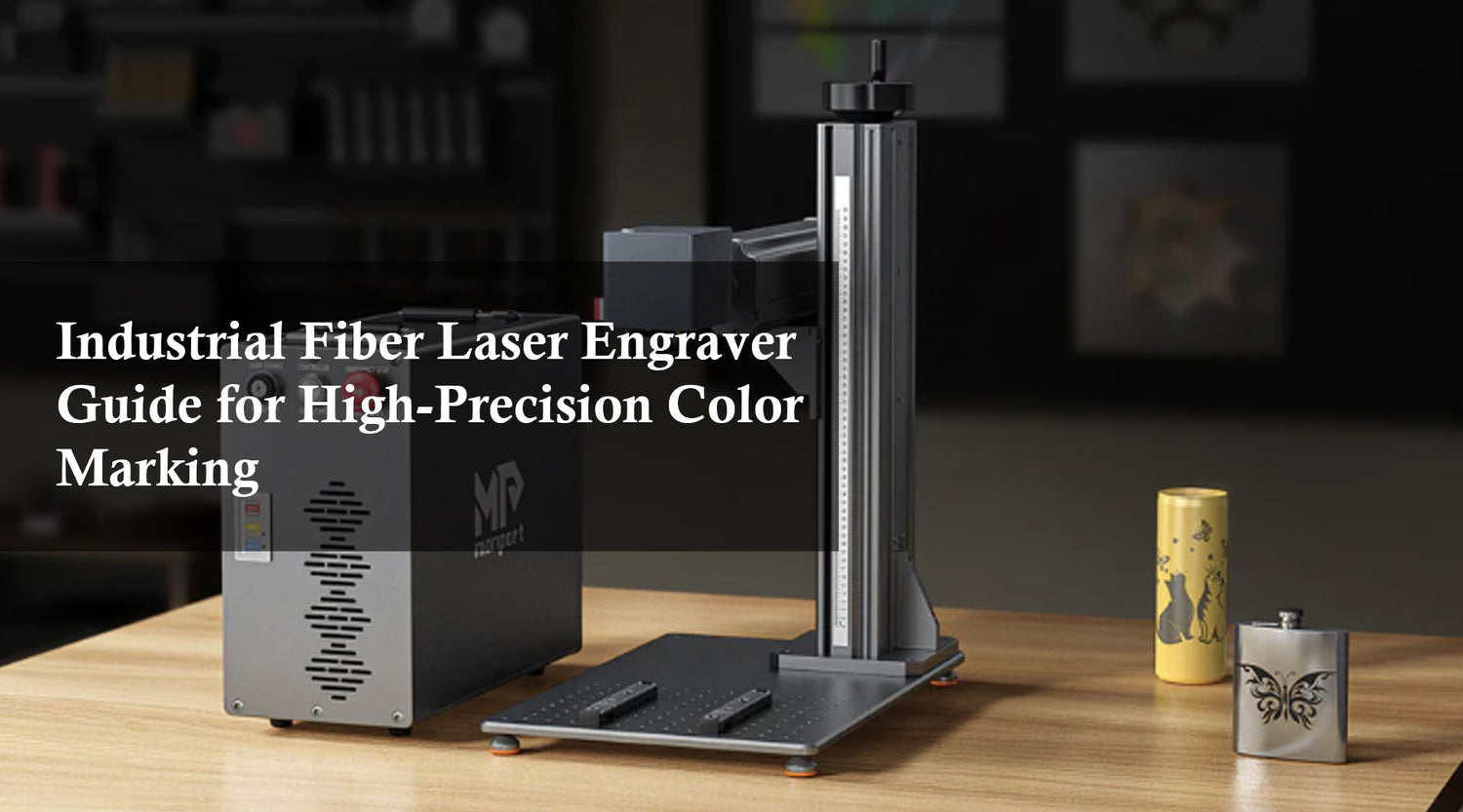

Monport 40W CO2 Laser Engraver: A Reliable Leather Engraving Laser

The Monport 40W CO2 Laser Engraver is a powerful option for both PU and genuine leather engraving.

-

Speed and Precision: Up to 350mm/s engraving speed ensures clean laser etching on leather.

-

Red Dot Guidance: Helps align designs accurately on leather surfaces.

-

Dual Work Table: Ideal for handling both irregular and flat leather pieces.

Troubleshooting Common Leather Engraving Issues

Even experienced users encounter issues when doing laser etching on leather.

-

Uneven Engraving: Ensure the leather lies flat.

-

Blurry Results: Adjust focus and power settings.

-

Burning or Melting: Reduce power or increase speed.

Before searching again for where can you get leather engraved, try adjusting your settings and testing small pieces.

Step-by-Step Guide to Laser Engraving PU Leather

-

Gather supplies, including PU leather, safety gear, and your leather engraving laser.

-

Prepare a ventilated workspace.

-

Import your design into Lightburn.

-

Test settings on scrap leather.

-

Clean and secure the leather.

-

Start the engraving process.

-

Allow the leather to cool.

-

Clean and finish the engraved piece.

This step-by-step process helps answer the common question, can you laser engrave leather successfully at home? Yes, with patience and testing.

Beyond PU Leather: Exploring Laser-Engravable Leather Types

PU leather is only one option. The Monport 40W also works well for laser etching on leather types such as:

-

Vegetable-tanned leather

-

Chrome-tanned leather

-

Suede leather

-

Tooled leather

-

Full-grain leather

Each material responds differently, so settings should always be adjusted. And once again, is PU leather safe for laser engraving? Yes, when proper ventilation is used.

Investing in Your Creative Journey

Laser engraving opens up endless creative opportunities. Instead of asking where can you get leather engraved, owning a leather engraving laser lets you create on your own schedule. Whether you’re engraving PU or genuine leather, understanding safety, testing materials, and refining settings makes all the difference. If you’ve ever wondered can you laser engrave leather reliably, the Monport 40W proves that you can.

Forget outsourcing. With the right setup, laser etching on leather becomes a skill you can master at home or in your workshop.

FAQs

Can you laser engrave leather at home?

Yes, with a desktop CO2 machine and proper ventilation, laser engraving leather at home is possible.

Is PU leather safe for laser engraving?

Is PU leather safe for laser engraving? Yes, but only with good airflow and protective equipment.

Where can you get leather engraved if you don’t own a machine?

Where can you get leather engraved? Makerspaces, libraries, and engraving shops often offer services.

What laser works best for laser etching on leather?

A CO2 leather engraving laser like the Monport 40W is ideal for leather projects.

Can PU be used for custom leather products?

Can PU be engraved and used for custom items? Yes, PU leather works well for decorative and budget-friendly projects when engraved carefully.

A high-quality leather engraving laser like the Monport 40W CO2 allows you to work confidently with PU and natural leather. From answering can you laser engrave leather to deciding where can you get leather engraved, the solution is clear: having the right machine gives you full creative control.

Celebrate Business Week with Monport! Enjoy up to 30% OFF on our premium laser engraving machines and unlock incredible free gifts to elevate your projects. Buy a CO₂ laser and receive a FREE Water Chiller, Rotary Axis, and LightBurn software. Purchase a Fiber Laser and get a FREE Rotary Axis. Plus, score a special $130 OFF on bundle deals and 30% OFF laser engraving materials. Don’t wait — use code BESTMP10 at checkout and click here to shop now!