Your Monport Mega 70W CO2 Laser is more than just a desktop engraving machine—it's the heart of your creative and professional engraving workflow. To keep this powerhouse running at peak performance, regular maintenance is key, and that starts with one crucial task: laser lens cleaning.

Whether you're a hobbyist or running a full-scale business, understanding the best practices for Monport Mega maintenance ensures your work remains crisp, precise, and consistent. In this laser lens cleaning guide, we’ll walk you through everything you need to know to protect your investment and get the most out of your desktop laser engraving machine.

Haven’t upgraded to the Monport Mega yet? Now is the perfect time to invest in the world’s premier 70W intelligent desktop laser engraving machine, designed for speed, power, and long-lasting precision.

Click here to order your Monport Mega now →

Let’s dive into the essentials of keeping your laser lens spotless and your machine running like new.

Why Laser Lens Cleaning Matters for Your Desktop Laser Engraving Machine

The laser lens is the heart of your engraving machine’s precision. It focuses the beam that engraves your design onto materials. Over time, residue, dust, smoke, and micro-debris can accumulate on the lens, especially when engraving wood, acrylic, or leather.

Neglecting to clean your lens can result in:

-

Reduced engraving accuracy

-

Burn marks or haze on your material

-

Overheating or even laser failure

-

Costly replacements

To avoid performance issues and extend the life of your Monport Mega, consistent laser lens cleaning is crucial.

Recommended Cleaning Schedule

Monport suggests the following Monport Mega maintenance intervals based on machine usage:

-

After 24 hours of engraving: Perform a complete component cleaning.

-

After 4 hours of cutting: Clean the laser head and lens thoroughly.

Always ensure the machine is powered off and unplugged before beginning any maintenance.

Step-by-Step Laser Lens Cleaning Guide

Here is a detailed cleaning protocol to maintain your desktop laser engraving machine and protect its most vital component:

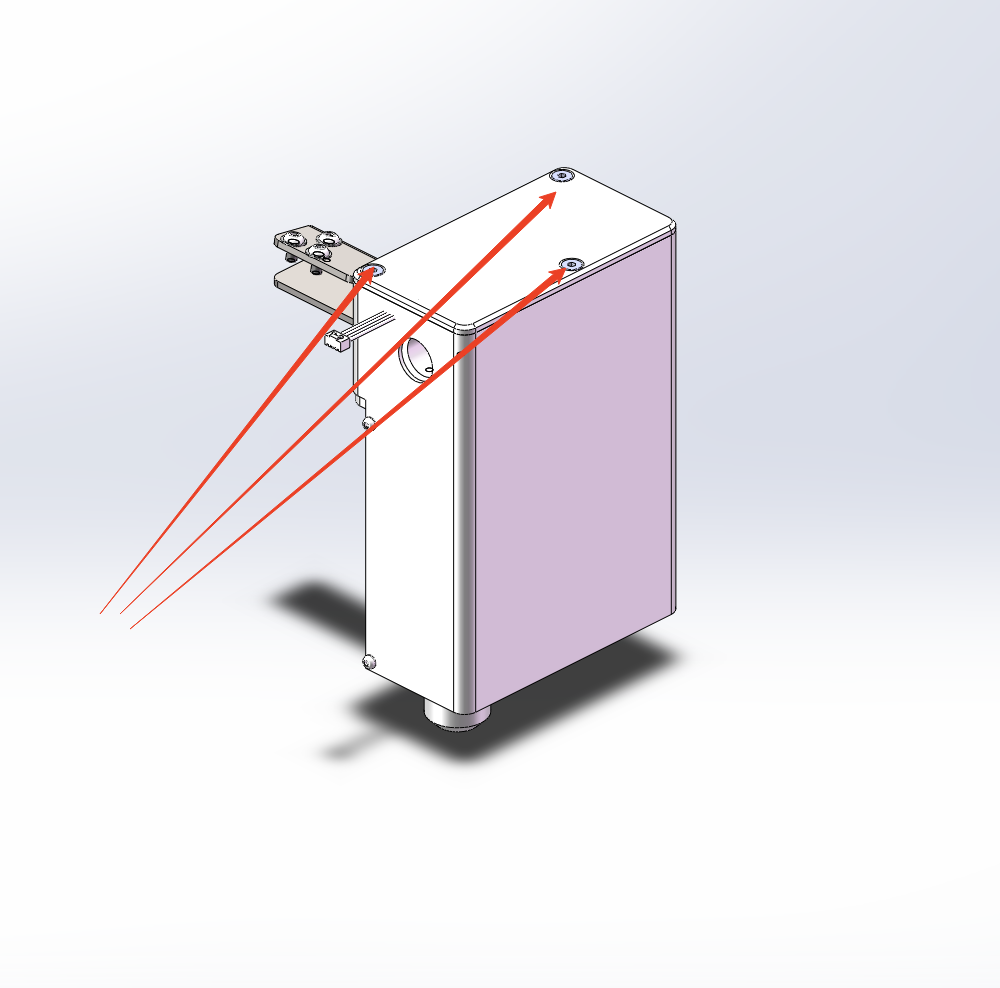

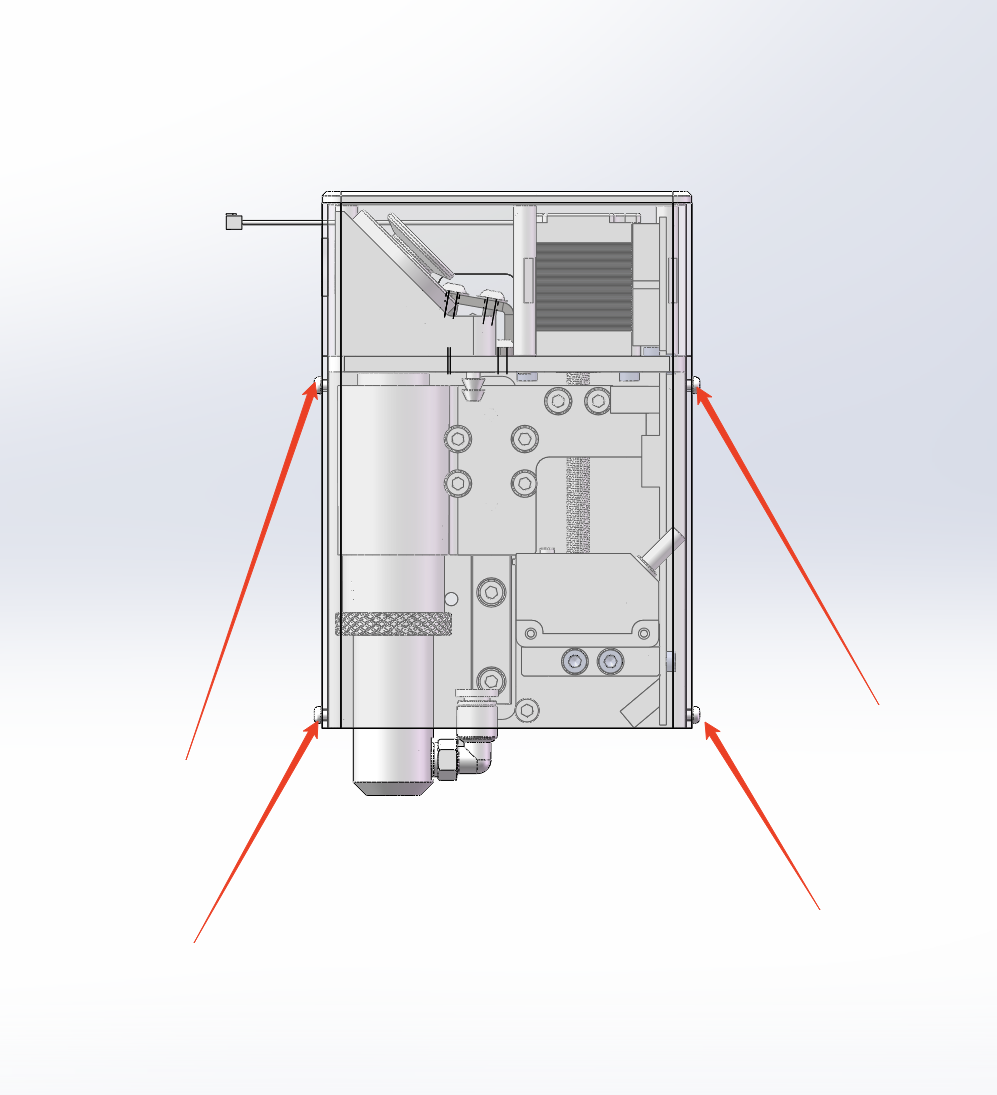

1. Disassembly of laser head housing

1) Remove the screws on the top cover and take off the top cover

2) Remove the screws on the side of the cover and slide it upwards to remove it.

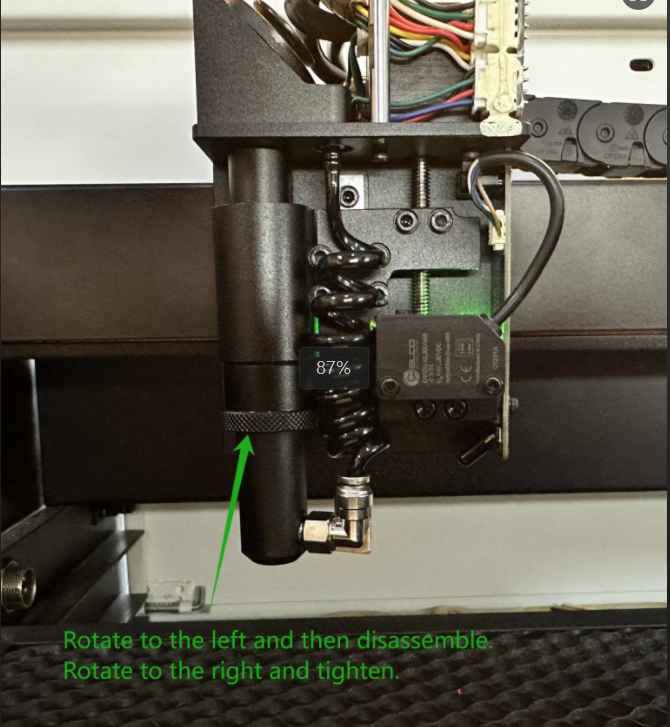

2. Disassembly of Laser Head Components

1) Remove the air nozzle component of the laser head and place it properly on a static-dissipative and clean work surface.

2) Remove the focusing lens mounting base and clean the base with alcohol and a dust-free cloth.

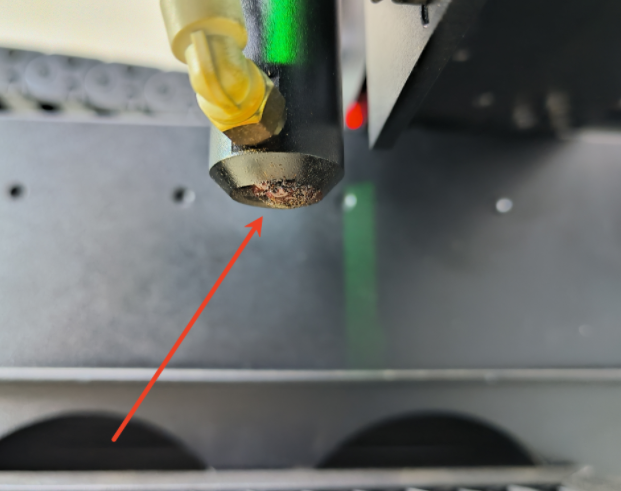

Clean the stains on the laser head. (It is necessary to clean it daily to prevent blockage caused by prolonged use.)

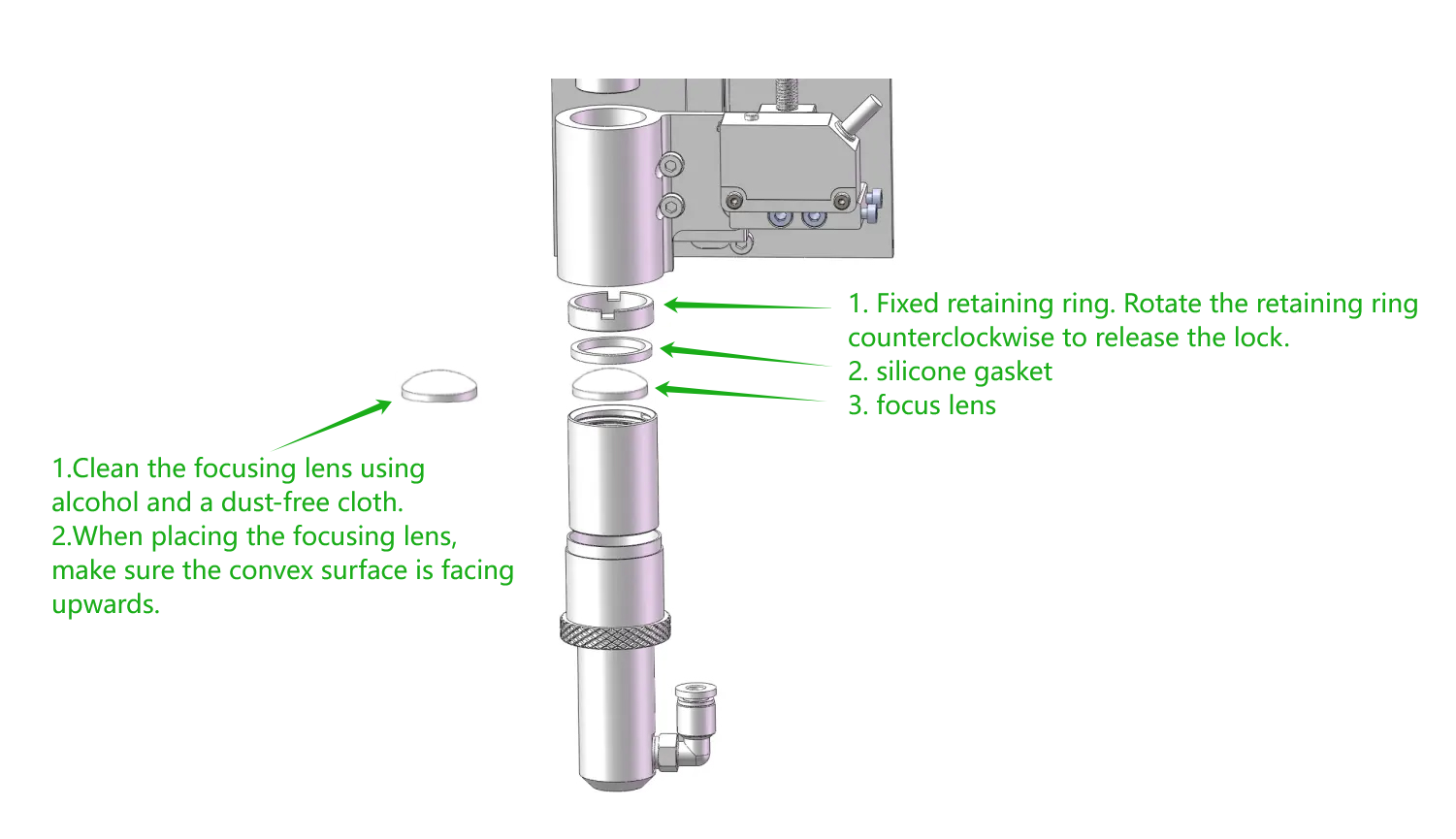

3. Lens disassembly

1) Remove the silicone sealing gasket and the focusing lens assembly one by one. Pay attention to recording the disassembly sequence of each component.

4. Cleaning Operations

1) Clean the focusing lens using alcohol and a dust-free cloth.

2) Wipe the lens radially in a single direction (do not rotate while wiping).

3) Check the integrity of the lens surface and confirm there are no scratches or burn marks.

5. Assembly and Reset

1) Ensure that the convex surface of the focusing lens is facing upwards.

2) Install the sealing components in reverse order according to the original disassembly sequence.

Notes:

● Avoid touching the focusing mirror surface with bare hands.

● The working environment should be kept clean.

Key Features That Enhance Monport Mega CO2 Laser

The Monport Mega is more than just a desktop laser engraving machine—it’s an intelligent system built with self-maintenance in mind:

-

Enclosed Track Design prevents dust from reaching critical internal components.

-

Auto-Focus System reduces the need for frequent manual adjustments.

-

Exceptional Air Duct System ensures clean operation by efficiently removing smoke and debris.

-

5-Minute Alignment System with visible low-power lasers simplifies the optical path calibration process.

All these innovations make the Monport Mega maintenance process easier, faster, and safer—especially when paired with a proper cleaning routine.

When to Replace Your Laser Lens

While routine laser lens cleaning helps extend the lens's lifespan, there are some signs that replacement may be necessary:

-

Persistent burn marks that won’t clean off

-

Noticeable engraving quality degradation

-

Visible cracks or pitting on the lens surface

If you observe these issues even after cleaning, consider ordering a replacement part to maintain your Monport Mega’s top-tier performance.

Final Thoughts: Keep Your Monport Mega Engraving Machine in Top Shape

Regular laser lens cleaning is a small but essential task that yields major long-term benefits for your desktop laser engraving machine. Whether you're running professional engraving operations or crafting personal projects, maintaining the lens ensures that your Monport Mega 70W CO2 Laser continues delivering clean, precise, and efficient results.

Don’t wait until performance drops—establish a cleaning routine and keep your Monport Mega maintenance top of mind.

Still Don’t Own the Monport Mega? Upgrade Today!

If you’re serious about precision, power, and professional results, the Monport Mega is the desktop laser engraving machine you’ve been waiting for. With 70W of intelligent engraving power, ultra-fast 600mm/s speed, autofocus, and an enclosed design built for safety and longevity, it's engineered to elevate your craft and your business.

Don’t miss out—order your Monport Mega now and experience the ultimate in laser engraving performance.

Monport Mega: The World's Premier 70W Intelligent Desktop Engraving Machine

Monport Mega: The World's Premier 70W Intelligent Desktop Engraving Machine