Ⅰ. Safety importance awareness

Since 1965, laser engraving has been used in many industries to engrave/cut materials, from diamonds to wood. As the application continues to be used for many industrial purposes, it is becoming more and more popular among schools, small businesses and even hobbyists.

However, operating the laser engraving and cutting system beyond the supplier's recommendations may cause serious injury and property damage to the operator. This blog lists some safety guidelines that must be strictly followed when using the laser engraving and cutting system.

What are the risks of using a CO2 laser engraver?

-

Beam exposure

Class 4 laser-the highest and most dangerous laser class. All devices with an output power of more than 0.5 watts fall into this category. This type of laser can burn the skin and cause permanent damage to the eyes due to direct or indirect (reflected) irradiation. High output power can easily ignite flammable materials, so they also pose a fire risk. Class 4 lasers are considered dangerous when not properly closed because they can cause damage to the skin, especially the eyes. As long as the laser beam is completely closed during operation, it will not hurt you. The transparent acrylic / polycarbonate window on the top of the laser will absorb any reflected laser beam because the infrared beam generated by the laser cutter (at this wavelength) is basically heat. In other words, you should still not stare at the cutting point for too long, because some materials will reflect part of the beam in the form of visible light. Many machines are equipped with aluminum cutting machines, which are highly reflective, so make sure to close the machine door when the laser is emitted and wear safety glasses when not closed (e.g. when aiming at the beam).

Lasers in cutting and engraving machines produce near-infrared and far-infrared spectra invisible to the naked eye. Because you can't see the laser beams, it's easy to forget where they are and try to do something you wouldn't have done, such as staring at a mirror or pulling out pieces of material while the machine is running. Even if you are very careful to avoid the beam, the laser head will often jump unexpectedly and move the beam in your direction.

-

Air Contaminants

Laser engraving&cutting machines produce smoke, steam, particles and metal fumes from highly toxic materials (plastics and other combustible materials). All laser cutting machine systems must be equipped with fume exhaust systems and filtering systems that meet the manufacturer's specifications. These fumes or air pollutants can damage the machine and harm your health. If the air filter or exhaust system is malfunctioning, immediately stop operating the laser cutting machine and notify your supervisor.

The filter must be replaced regularly according to the frequency of use or the manufacturer's regulations.

-

Material hazards

Due to the flexibility of modern laser engraving and cutting machines, it is easy to forget that not everything can be processed safely. For example, when PVC burns, it produces hydrochloric acid, carbon monoxide, dioxins and chlorinated furans, which can severely damage the machine, but even more serious is a major health risk to anyone near the machine.

If you have any questions, be sure to discuss your requirements with the material manufacturer before starting work and obtain copies of their appropriate health and safety documents.

-

Fire

Laser cutting machine uses concentrated heat to burn some materials, so it will bring real fire safety problems. The danger comes not from the laser itself, but from the material being cut. Some materials (such as acrylic) are more flammable than others and may explode into open fire. Small flame combined with smoke exhaust fan will suck a large amount of fresh air into the machine. If it is not handled immediately, it will soon become a comprehensive fire. I just need a few minutes.

The most important thing is not to leave the machine unattended when it is running, no matter how tedious the cutting or engraving process is. A properly functioning compressor provides a sufficient air supply for the machine nozzles, which can remove smoke, debris and smoke, and minimize the risk of flame ignition during processing. Therefore, the effectiveness of the air-assisted compressor should be checked regularly.

Monport Laser has strict policies on machine safety training. Each of our machines has warning labels, warnings and notices in the operating manual. When we provide new machines, machine supervision is a very clear element of our training program. As part of our standard training program, every customer will fully understand the risks of unattended machines.

Cleanliness is a very important factor in reducing the risk of fire. When cutting certain materials such as wood and plastic, potentially flammable deposits may accumulate on the machine tool. If allowed to accumulate, they will increase the risk of fire. Solving this risk is simple: just clean the deposits in the bed regularly.

Always place an easily accessible fire extinguisher next to the machine. Since electricity is involved and you may need to deal with the fire while the machine is still plugged in, we recommend using CO2 or other electrically compatible fire extinguishers. Monport Laser recommends that appropriate personnel be trained in the use of fire extinguishers. The keys to operate the machine can only be used by qualified personnel with appropriate training.

Basic machine management is always recommended as a good practice. Keep your cabinet clean, free of dust and material scraps. Incorporate regular cleaning and maintenance policies as part of your operating system. No matter what brand your laser machine is, do not leave it unattended or operated by unauthorized personnel.

Ⅱ. How to keep safe?

The CO2 laser engraving and cutting machine with a laser wavelength of 10.64μm is harmful to human skin when working, so operators should pay attention to safety during use. When the laser engraving and cutting machine is working, it is very dangerous if it breaks down. Novices must be trained by professionals before they can operate independently. Based on our experience, we have summarized 13 details of the safe operation of the laser cutting machine, hoping to help friends who are using the laser equipment. The operation details are as follows:

- Observe the safety operation procedures of general laser equipment. Start the laser in strict accordance with the laser starting procedure.

- Operators must be trained, familiar with equipment structure and performance, and master relevant knowledge of operating system.

- Wear labor protection articles as required, and wear qualified protective glasses near the laser beam.

- Do not process a material before it is clear whether it can be irradiated or heated by laser, so as to avoid the potential danger of smoke and vapor.

- When the equipment is started, the operator shall not leave the post or entrust someone to be in charge without authorization. If it is really necessary to leave, stop the machine or cut off the power switch.

- Put the fire extinguisher in an accessible place; Turn off the laser or shutter when not processing; Do not place paper, cloth or other inflammables near unprotected laser beams.

- In case of any abnormality during processing, stop the machine immediately, eliminate the fault in time or report to the supervisor.

- Keep the laser, bed and surrounding site clean, orderly and free of oil stain, and stack workpieces, plates and wastes according to regulations.

- High voltage safety regulations shall be observed during maintenance. Maintenance shall be carried out every 40 hours of operation or weekly maintenance, every 1000 hours of operation or every six months in accordance with regulations and procedures.

- After startup, manually start the machine tool at low speed in X and Y directions to check whether there are abnormalities.

- After inputting the new workpiece program, it shall be commissioned first and its operation shall be checked.

- During operation, pay attention to the operation of the machine tool to avoid accidents caused by the cutting machine out of the effective travel range or the collision between the two machines.

- During the operation of the laser cutting and engraving machine, the protective cover on the laser machine must be lowered to prevent the laser beam from injuring people.

Routine and preventive maintenance optimize the safety and performance of your laser machine. It requires just a few minutes of regular maintenance to prolong the service life of your machine.

Ⅲ. What protective devices does a Monport laser engraving machine have?

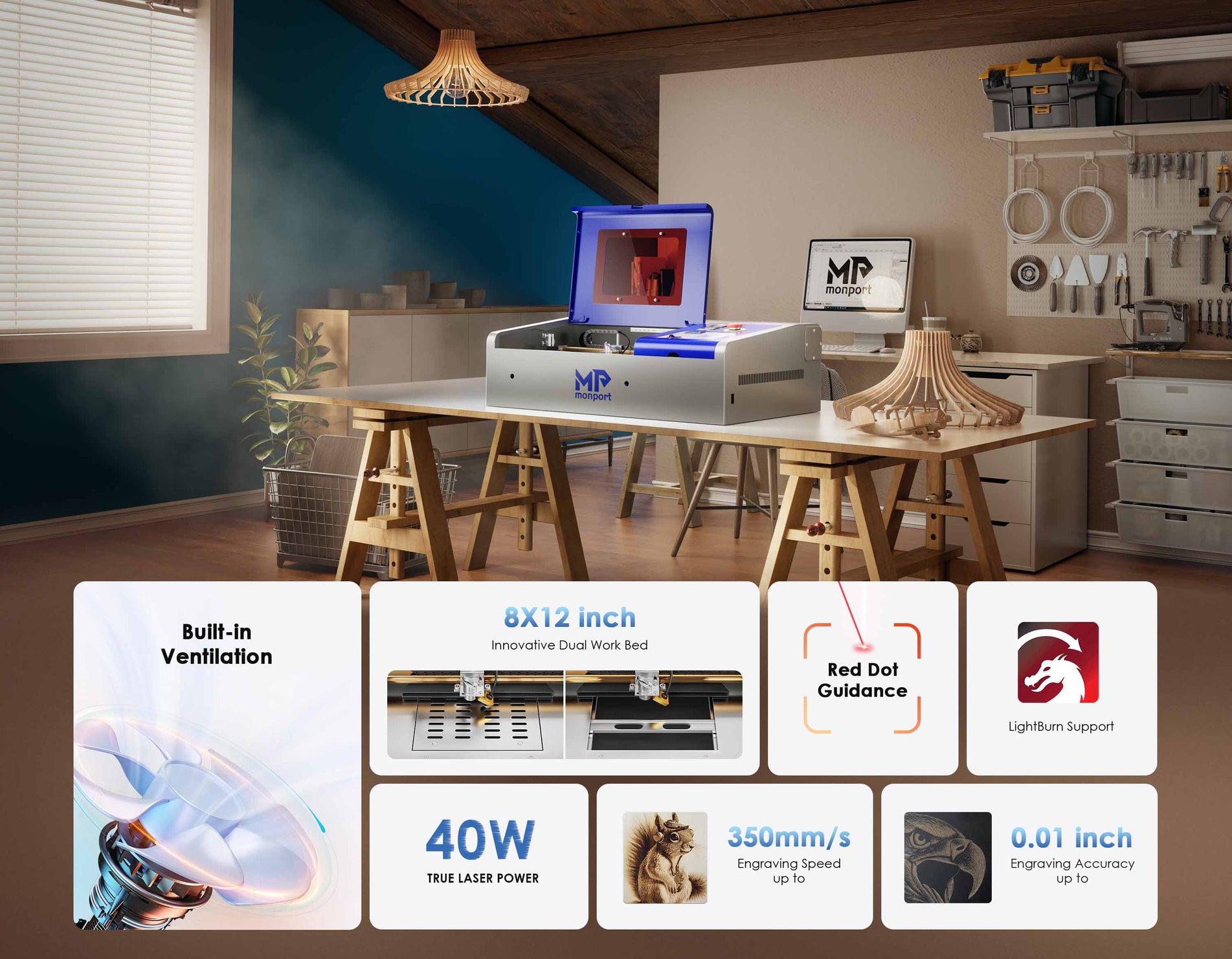

All Monport laser machines comply with CE standards. Here you can find an overview of machine specific safety and protection devices that Monport machines have:

Smart Safety Sensor

The safety shutdown sensor helps stop the machine when opening the transparent window cover. Once closed, press the “Enter” button to continue operation.

Protective cover

For all closed laser systems, e.g.: Monport 55w Co2 Laser Engraving & Cutting Machine, the acrylic cover provides extensive protection from the laser light. Due to the brunet acrylic plate, the laser light is completely absorbed. Therefore, user’s eyes are protected from laser irradiation.

Safety switch for immediate interruption of the power source

In a dangerous situation, the power source can be interrupted by various safety switches and buttons. The laser process is stopped immediately.

- Key switch: Laser supply and electronics are de-energized. When you take down the key, you can prevent children from opening the machine unattended. For children, this key switch is safer than a simple button.

-

Emergency stop button: Electric circuit is interrupted, all actions are stopped. At present, the emergency stop button of the existing laser engraving machine can not turn off the laser beam. However, we will make an improvement that once you press the emergency button, the motor and laser power supply also can be stopped in the future.

When installing your Monport laser engraving and cutting machine, you will receive integrated instructions regarding safe handling of the laser. If you have any questions about laser engraving and cutting operation safety that are not mentioned here, please feel free to contact us via live chat, by phone at 1-800-829-493, or support@monportlaser.com.