As a common engraving material, stainless steel marking can be found in a variety of industries including home furnishings, jewelry, and many others. A stainless steel engraver marking machine can be used to engrave or mark stainless steel for different applications.If you own a small metal laser engraving business, this article will provide you with more engraving and marking technology as well as how to engrave stainless steel. Learn the best method for laser engraving stainless steel with Monport GA MOPA fiber laser engraver.

Monport GA 60W Upgraded Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus

Read More : Master Metal Engraving with the Best Budget Laser Engravers

Choose the Best Laser Engraving Machine

Without a doubt, the fiber laser engraving machine, which is more effective than CO₂ lasers, is the best option for how to engrave stainless steel. This is now widely accepted as the top method for achieving durable and detailed metal marking. The Monport fiber laser uses doped fiber to produce a wavelength of around 1.06 microns, ideal for marking metals like stainless steel, aluminum, and brass with deep, crisp detail.

While CO₂ lasers typically cater to nonmetals, you can still engrave stainless steel by using a laser engraving stainless steel spray, such as CerMark or LaserBond. These sprays pre-treat the surface, allowing CO₂ lasers to mark stainless steel effectively. However, for professional use and deeper marks, fiber stainless steel engravers remain the top choice.

How to Engrave Stainless Steel

Stainless steel is a popular material for laser marking due to its durability and resistance to corrosion. However, laser engraving can be challenging because of its reflective surface, which can damage the laser. Here are proven techniques, including the use of laser engraving stainless steel spray, to achieve clean, professional results:

Use vector images

Vector images are made up of mathematical equations and can be scaled to any size without losing quality. This makes them ideal for cutting or etching lines into stainless steel. It's best to use vector images in formats like .AI, .EPS, .SVG.

Choose the right font

Because stainless steel is a hard, durable material, it's important to choose a font that has thick lines and a bold appearance. This will make the engraving more visible and easier to read.

The best font for engraving for laser engraved stainless steel using a fiber laser engraver is a sans-serif font with clean lines, such as Arial or Helvetica, because they provide clear and legible text that is easily readable. Other good options include Calibri and Verdana.

When selecting a font, it's important to consider factors such as the size and thickness of the letters, as well as the overall contrast between the font and the background material.

Masking

This process is applied when you don't want the laser beam to touch certain areas of the stainless steel. A special tape or coating is applied to the area that needs to be masked, and this will protect them from the laser beam during the engraving process, ensuring precise and controlled laser engraved stainless steel results.

There is no need for pretreatment on laser engraved stainless steel. You can make visible marks on the surface, but you'll need to use a special compound to make deeper marks. It is commonly referred to as metal marking spray. Spray a thin, even layer of paint on the metal. The laser beam then reacts with this compound, leaving a more visible dark mark, which enhances the stainless steel marking process.

Use high contrast colors

Stainless steel is a shiny and reflective surface, so it's important to use high contrast colors to make the engraving stand out. Avoid using colors that are similar to the color of the laser engraved stainless steel, as they will not be visible.

Clean the surface

It is important to clean the stainless steel surface before engraving to remove any dirt, oil, or other contaminants that may affect the engraving quality.

Anodized Coating

Applying an anodized coating to the stainless steel before engraving will also help to reduce reflectivity and increase the contrast of the engraved design. Anodizing is a process where a thin oxide layer is formed on the surface of the stainless steel; this helps to protect the steel and also makes it more receptive to the laser beam, improving the stainless steel marking process for clearer, more vibrant laser engraved stainless steel results.

Using the right laser wavelength

Generally, a 20W fiber laser can easily finish the marking of stainless steel at one time. Some laser wavelength are better absorbed by stainless steel than others. Using a wavelength that is absorbed more readily by the steel can increase the efficiency of the engraving process.

Applications

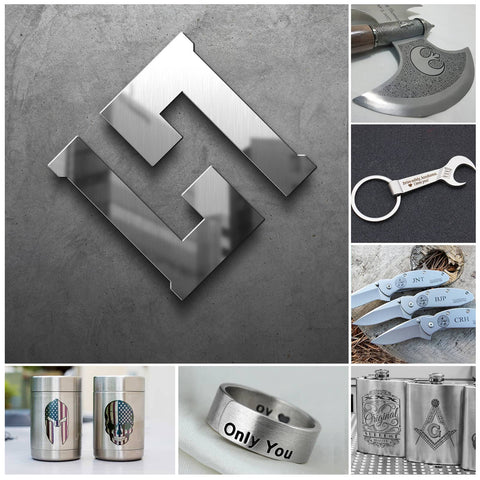

Stainless steel is widely used and can be used in many applications. When used with a laser marking machine for marking and engraving stainless steel, you can significantly expand your product line and processing capacity. Some common applications of laser engraving and marking stainless steel and other metals include:

- Personalized jewelry, such as pendants, bracelets, and rings.

- Memorial plaques, such as for dedications or memorials.

- Custom signage, such as for business logos or directional signs.

- Gift items, such as photo frames, keychains, and money clips.

- Housewares, such as coasters, wine stoppers, and picture frames.

- Corporate gifts, such as pens, lighters, and desk accessories.

FAQs About Laser Engraving Stainless Steel

Can you laser engrave stainless steel permanently?

Yes, laser engraving on stainless steel produces permanent marks that resist fading, corrosion, and abrasion.

Is fiber laser required for laser engraving stainless steel?

Fiber systems are the most efficient option for laser engraving stainless steel, especially for deep or high-volume engraving.

What thickness works best for laser engraving stainless steel?

Laser engraving stainless steel works on thin and thick materials, but settings should be adjusted based on material thickness.

Does surface finish affect laser engraving results?

Yes, polished surfaces reflect more light, while matte finishes often produce better contrast when laser engraving on stainless steel.

Final Thoughts

Laser engraving on stainless steel is a reliable solution for creating precise, long-lasting markings across commercial and creative applications. By using the right machine, preparing materials properly, and optimizing engraving settings, laser engraving stainless steel can deliver consistent, professional results for any production scale.

Celebrate Business Week with Monport! Enjoy up to 30% OFF on our premium laser engraving machines and unlock incredible free gifts to elevate your projects. Buy a CO₂ laser and receive a FREE Water Chiller, Rotary Axis, and LightBurn software. Purchase a Fiber Laser and get a FREE Rotary Axis. Plus, score a special $130 OFF on bundle deals and 30% OFF laser engraving materials. Don’t wait — use code BESTMP10 at checkout and click here to shop now!