Today, technology empowers woodworkers with innovative tools for wood engraving like lazer wood cutters, expanding the realm of possibility. From intricate furniture embellishments to custom signage, wood's natural beauty serves as a timeless canvas for creative expression.

This comprehensive guide explores the exciting world of wood engraving tools, comparing traditional methods with the cutting-edge capabilities of lazer etching wood cutters, including the Monport 80W CO2 Laser Engraver.

Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus

Traditional Tools for Wood Engraving

Wood engraving has a rich history, and the basic tools for wood engraving remain relatively unchanged. Let's delve into the essentials:

- Gouges: These handheld tools, featuring U-shaped blades, come in various sizes and shapes for precise wood removal. Gouges allow for detailed carving and shaping.

- Chisels: Offering a sharp, straight edge, chisels are ideal for creating crisp lines and removing larger sections of wood.

- Knives: Sharp carving knives provide versatility for detailed cuts and intricate patterns.

- Mallets: Mallets are used to safely strike gouges and chisels, ensuring controlled application of force.

- Sharpening Stones: Maintaining razor-sharp tools is crucial. Sharpening stones ensure clean cuts and prevent wood damage.

While these tools for wood engraving offer a classic approach to wood engraving, they require substantial skill and practice to master. In contrast, lazer etching provides a more efficient and precise alternative, allowing for intricate designs with less manual effort and a quicker learning curve.

The Rise of Laser Wood Cutters: A New Era of Precision

Lazer wood cutters revolutionize tools for wood engraving by utilizing a focused beam of light to vaporize wood particles, creating precise cuts and intricate designs. Here's what sets them apart:

- Unmatched Precision: Lazer wood cutters achieve incredible detail and accuracy, surpassing the capabilities of even the most skilled hand tools.

- Versatility: These machines can engrave and cut a wide range of materials beyond wood, including acrylic, leather, and glass, opening doors to diverse creative projects.

- Scalability: Laser wood cutters handle projects of various sizes, from small keychains to large signage, making them suitable for hobbyists and businesses alike.

- Repeatability: Laser engraving software allows for precise design creation and ensures consistent results on every project.

- Minimal Waste: Laser cutting minimizes material waste compared to traditional methods that involve wood removal.

Introducing the Monport 80W CO2 Laser Engraver: Power and Precision

The Monport 80W CO2 laser etching Engraver exemplifies the latest advancements in laser wood cutting technology. Here are some key features that make it a powerful tool for wood engraving enthusiasts:

- Spacious Work Bed: The 16" x 24" work bed accommodates larger wood projects, while the four-way pass-through allows for engraving on materials that extend beyond the work area.

- Material Compatibility: This laser engraver works seamlessly with various materials, including wood, glass, acrylic, and leather, offering engraving depths of up to 0.59 inches.

- High-Performance Laser Beam: The jointly developed laser beam by Monport & Yongli boasts an impressive lifespan of 12,000 hours and delivers a superior actual RP (Rasterization Parameter) for optimal engraving results.

- Intelligent Control Panel: The intuitive panel provides direct control of auto-focusing, Z-axis movement, and air assist. It also offers a dynamic display of the engraving process, allowing for real-time adjustments and progress tracking.

- Advanced 4-in-1 Laser Head: This innovative head combines laser emission, autofocus, air assist, and red light indication for streamlined operation and enhanced engraving accuracy.

- Comprehensive Safety Features: User safety remains a priority. Features like an emergency stop button, independent laser control, cover protection, and auto-stop mechanisms ensure a safe working environment.

Choosing the Right Tool for Wood Engraving

The choice between traditional wood engraving tools and a lazer wood cutter depends on your specific needs and preferences. Here's a quick comparison:

- Traditional Tools: Ideal for those who enjoy the tactile experience of woodworking and developing their carving skills. However, mastering these tools requires significant practice and dexterity.

- Lazer Wood Cutters: Offer unparalleled precision, speed, and design flexibility, making them perfect for intricate projects, replicating designs, and achieving consistent results. While they require an initial investment, laser wood cutters can significantly enhance your creative workflow.

Mastering the Monport 80W CO2 Laser Engraver: Machine Guide, Settings, and Maintenance

Now that you've explored the world of wood engraving tools and the advantages of laser etching wood cutters, let's delve deeper into the Monport 80W CO2 laser etching Engraver. This section equips you with the knowledge and resources to operate your machine effectively and achieve stunning results on wood projects.

Machine Guide and Settings:

-

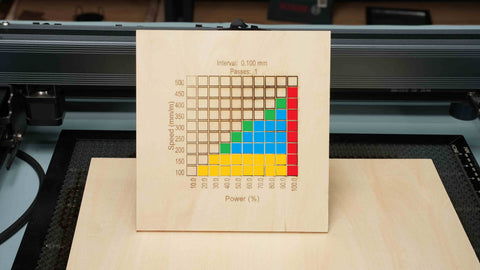

Understanding Laser Power and Speed: Laser power and speed are the two critical parameters that determine the quality of your engraving or cutting results.

- Laser Power: Measured in watts (W), laser power dictates the depth of engraving or the cleanness of cuts. Higher power settings result in deeper cuts but can also cause charring on wood. Conversely, lower power settings produce shallower engravings but minimize burning.

- Speed: Speed, measured in millimeters per second (mm/s) or inches per second (in/s), determines how quickly the laser beam travels across the material. Slower speeds allow for deeper engraving or cleaner cuts, while faster speeds are suitable for shallow engravings or rastering (filling areas with dense engraving patterns).

-

Recommended Settings for Wood Engraving: The optimal settings for wood engraving depend on the specific type of wood, its thickness, and your desired outcome. Here's a general starting point:

- Wood Type: For common woods like pine, birch, or maple, a starting power range of 15% to 30% and a speed range of 300 mm/s to 500 mm/s is recommended for engraving. Adjust these based on the factors mentioned above.

- Cutting Wood: For cutting through wood, increase the power to 60% or higher and adjust the speed based on the wood thickness. Aim for slower speeds for thicker wood to ensure clean cuts.

Tips and Techniques for Wood Engraving:

- Experiment with Different Settings: Always begin with test engravings on scrap wood to determine the ideal settings for your project.

- Utilize LightBurn Software: LightBurn, the included software, offers user-friendly features for design creation, power and speed adjustments, and layer control for complex engravings.

- Control Rasterization and Vector Settings: LightBurn allows you to define areas for raster engraving (filling) and vector cutting (outlines). Adjust raster and vector settings independently to achieve desired results.

- Maintain Proper Ventilation: Wood engraving generates smoke and fumes. Ensure adequate ventilation in your workspace to remove these particles and maintain good air quality.

- Use High-Quality Wood: For optimal results, choose wood that is free of knots, cracks, and moisture content within the recommended range (typically 8% to 15%).

Troubleshooting Common Issues:

- Blurry or Uneven Engravings: This could be caused by improper focusing, unstable material placement, or loose belts on the laser head carriage. Ensure the laser is correctly focused on the wood surface, and check for any mechanical issues with the machine.

- Material Not Cutting Through Completely: Increase the laser power or decrease the cutting speed. Ensure your settings match the material thickness.

- Erratic Laser Beam: Consult the user manual for troubleshooting steps. This could be a sign of a faulty laser tube or a problem with the control board. If unable to resolve, contact Monport customer support.

Maintenance for Optimal Performance:

- Cleaning the Laser Lens: Regularly clean the laser lens with a soft, lint-free cloth to remove dust or debris that can affect engraving quality.

- Mirror Maintenance: The mirrors within the laser path should also be kept clean. Refer to the user manual for proper cleaning procedures.

- Water System Maintenance: If your Monport 80W CO2 Laser Engraver features a water cooling system, ensure the water level remains within the recommended range and replace the water periodically to prevent overheating.

- Software Updates: Check for and install any available software updates from Monport to ensure compatibility and access to the latest features.

The Future of Wood Engraving: A Fusion of Tradition and Technology

The future of wood engraving lies in the synergy between traditional craftsmanship and innovative tools like laser etching wood cutters. While lazer cutters offer unmatched precision and efficiency, traditional techniques add a personal touch and a deeper understanding of the material. By embracing both approaches, woodworkers can unleash their creative potential and bring remarkable visions to life.

Visit the Monport website today to explore the Monport 80W CO2 Laser Engraver and discover a world of creative possibilities for your wood projects. We offer comprehensive resources, including video tutorials and user manuals, to guide you on your laser engraving journey.

Embrace the future of wood engraving with Monport!