Engraver on wood, a craft steeped in tradition, has captivated artisans for centuries. From intricate furniture pieces to charming decorative accents, the ability to transform raw wood into functional and beautiful objects has always held a special place in human creativity. While time-honored methods like hand carving and burning tools have long been the cornerstone of this craft, technology is ushering in a new era – laser engrave wood. This innovative approach utilizes a focused beam of light to etch designs onto wood surfaces, offering a plethora of advantages that are fundamentally reshaping the landscape of woodworking. With advancements in technology, the wooden cut machine is becoming an essential tool for modern woodworkers, allowing for seamless precision and enhanced creativity.

Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro

Beyond the Chisel: Exploring Traditional Engraver on Wood Methods

For generations, wood engraving has relied on skilled artisans wielding handheld tools to bring their visions to life. Wood engravers, typically crafted from steel, allow for detailed designs to be pressed into the wood surface. While requiring a steady hand and meticulous attention to detail, this technique produces a unique charm and a distinctive tactile quality. Burning tools, on the other hand, utilize heated tips to create darkened lines and patterns on the wood. This method offers a more rustic aesthetic and can be used for decorative purposes or for creating text.

However, both traditional methods have limitations. Hand engraving, by its very nature, is a time-consuming process, and achieving intricate details can be challenging. Burning tools can also lead to uneven burning or unwanted charring of the wood, making a wooden cut machine a valuable alternative.

A New Dawn: Unveiling the Power of Laser Engraving on Wood

Laser engraving on wood marks a significant leap forward in this age-old craft. This technology harnesses a concentrated beam of light to meticulously remove thin layers of wood, creating permanent and highly detailed designs. Unlike traditional methods, laser engraving offers a multitude of benefits for woodworkers:

Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro

-

Unmatched Precision and Detail: Laser technology delivers pinpoint accuracy, allowing for the creation of incredibly intricate designs, logos, text, and even photographs. This opens doors to a world of possibilities, from personalizing cutting boards and decorative pieces to crafting unique signage and intricate inlays, making it an ideal companion to a wooden cut machine.

-

Speed and Efficiency: Compared to traditional engraving methods, laser engraving boasts exceptional speed. The laser beam can move rapidly across the wood surface, drastically reducing project turnaround times. This efficiency is especially beneficial for large-scale projects or businesses that require high production volumes.

-

Repeatability and Consistency: The digital nature of laser engraving ensures consistent and repeatable results. Every engraving is a perfect replica of the original design, eliminating the potential for human error and guaranteeing identical pieces, even in large quantities when using a wooden cut machine.

-

Clean Cuts and Minimal Burning: Laser engraving produces a clean and precise cut with minimal burning or charring on the wood surface. This eliminates the need for extensive post-processing steps, saving time and effort. Additionally, the clean cuts contribute to a sharper and more professional-looking final product.

-

Versatility Across Wood Types: While some traditional engraving methods might be limited in their application, laser engraving thrives on versatility. This technology can be used on a wide range of wood types, from hardwoods like mahogany and walnut to softer woods like pine and basswood. This allows woodworkers to experiment with different materials and expand their creative possibilities.

Introducing the Monport Desktop CO2 Laser 40W: A User-Friendly Engraving Powerhouse

The Monport Desktop CO2 Laser 40W is a prime example of how laser engraving technology is empowering woodworkers of all skill levels. This user-friendly desktop machine boasts a compact design, making it ideal for workshops of all sizes. Here's how the Monport 40W laser engraver on wood elevates the wood engraving experience, especially when paired with a wooden cut machine:

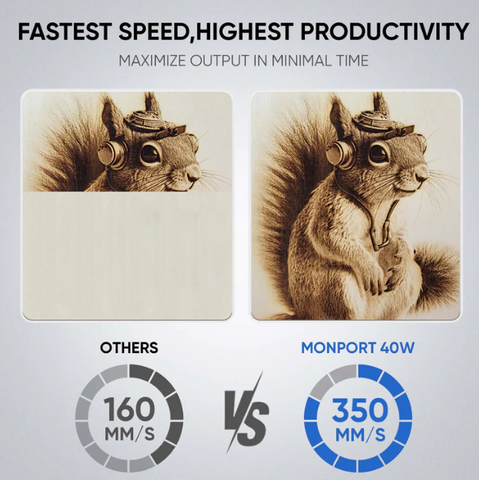

- Exceptional Speed and Precision: With engraving speeds reaching up to 350mm/s and an engraving accuracy of 0.01 inches, the Monport 40W Pro delivers sharp and detailed results in record time.

- Lightburn Compatibility: This Monport laser engraver on wood seamlessly integrates with Lightburn, the industry's leading design software. This opens doors to a vast library of design options and allows for precise control over the engraving process.

- Built-in Air Assist: One of the key highlights of the Monport 40W Pro is its built-in air assist feature. This system helps to reduce wood discoloration during engraving, ensuring clean and pristine results on your wood projects.

- Easy to Use: The Monport 40W is designed with user-friendliness in mind. The intuitive control panel and readily available software support make it easy to learn and operate, even for engraver on wood beginners.

Troubleshooting Tips for Laser Engraver on Wood with Your Monport Desktop CO2 Laser 40W

While laser engrave wood offers a multitude of benefits, there can be occasional hiccups during the process. Here are some troubleshooting tips to help you achieve optimal results with your Monport Desktop CO2 Laser 40W engraver on wood:

Uneven Engraving

- Material Consistency: Ensure your wood surface is smooth and free of knots, cracks, or uneven textures. These inconsistencies can cause the laser to engrave at different depths, resulting in an uneven finish. Consider sanding the wood for a uniform surface.

- Focus Calibration: Verify that your laser focus is properly calibrated. Refer to your Monport user manual for specific calibration instructions. An improperly focused laser beam can lead to uneven engraving depth.

- Artwork Optimization: Double-check your engraving artwork for any inconsistencies or stray lines. Uneven lines in the design will translate to uneven engraving on the wood.

Burning or Charring

- Laser Power Settings: Start with lower laser power settings and gradually increase them as needed. Excessive power can scorch the wood. Consult the recommended power settings for your specific wood type and desired engraving depth in the Monport Laser engraver user manual or online resources.

- Engraving Speed: Engraving speed plays a crucial role. A slower engraving speed allows the laser to remove material more precisely, minimizing burning. Experiment with different speeds to find the optimal setting for your project.

- Air Assist Function: Ensure the built-in air assist function on your Monport 40W is activated. The air flow helps to remove smoke and debris from the engraving area, preventing burning and charring.

Light Burning or Lack of Depth

- Laser Power Settings: If you're experiencing light engraving or a lack of depth, gradually increase the laser power settings while monitoring the results.

- Material Thickness: Consider the thickness of your wood in relation to the desired engraving depth. For deeper engravings on thicker wood, you might need to adjust power settings or perform multiple engraving passes.

- Multiple Passes: You can achieve deeper engravings by performing multiple passes over the same area. However, adjust the laser power slightly between passes to avoid excessive burning.

General Tips

- Software Compatibility: Ensure you're using compatible design software with your Monport laser engraver. The Monport 40W is optimized for Lightburn software, which offers precise control over engraving parameters.

- Material Selection: Different wood types respond differently to laser engraving. Experiment with various woods to find the ones that produce the best results for your desired aesthetic.

- Cleaning and Maintenance: Regularly clean the lens of your laser engraver to maintain optimal beam quality. Refer to your user manual for proper cleaning instructions.

Remember: When troubleshooting, it's always best to start with small adjustments and observe the results before making significant changes. If you encounter any persistent issues beyond these tips, consult the Monport user manual or contact their customer support for further assistance.

While these tips can address most engraving issues, proper mirror alignment is crucial for optimal laser performance. For a more in-depth visual guide on mirror alignment, check out this helpful video:

Mastering this step will ensure your laser beam is precisely focused, delivering clean and crisp engravings on your woodworking projects.

By following these tips and familiarizing yourself with your Monport Desktop CO2 Laser 40W, you can overcome common challenges and achieve stunning results on your wood engraving projects. Happy creating!

Effortless Laser Marking with Monport Black Laser Marking Spray

Looking to elevate your laser engraving projects? Monport Black Laser Marking Spray is the solution you’ve been waiting for. This high-performance aerosol spray is designed for use with CO2 laser engraving machines, ensuring easy and precise results with every application. Whether you're personalizing jewelry, customizing glassware, or serializing tools, this spray provides you with high-contrast, permanent marks that stand out.

The Benefits of Using Black Laser Marking Spray

-

Compatible with CO2 Laser Engraving Machines Designed for use with CO2 laser engraving machines of 25 watts and above, Monport Black Laser Marking Spray is the ideal companion for your engraving needs. It transforms your metal surfaces into highly legible, permanent black marks after laser engraving, making it perfect for a wide range of applications from metalwork to custom art pieces.

-

Permanent, High-Contrast Marks When you apply Monport Black Laser Marking Spray, the result is a high-contrast, dark black mark on your metal surface that is permanent and durable. This spray works on various metals, including aluminum, stainless steel, and brass. The fine-grained formula ensures deep penetration into the metal, producing heat-resistant markings that will last for years, even under challenging conditions.

-

Even and Powerful Application With the advanced spray technology in Monport Black Laser Marking Spray, you can achieve a smooth, even application every time. The 14 oz can features an anti-clog nozzle that guarantees no blockages, making the spray process both easy and efficient. The nanoparticle formula delivers more coverage with a thinner coating, which results in a professional-quality finish for all your metal marking projects.

-

Easy to Use and Quick Drying Using Monport Black Laser Marking Spray couldn’t be simpler. Just shake the can for 2 minutes, spray from a distance of 6 to 8 inches, and let the surface dry for 5 minutes. Once it’s dry, you’re ready to engrave, saving you valuable time. After engraving, rinse and wipe away the residue to reveal your crisp, dark black markings without any fuss.

-

Effortless Cleanup and Maintenance After marking your metal pieces, simply rinse and wipe the surface to reveal your high-contrast engraving. The black laser marking spray ensures there is no residue left behind, so your workpieces remain clean and ready for immediate use. The easy cleanup means that you can maintain a smooth and efficient workflow, whether you’re working on a small DIY project or a larger-scale production.

Why Choose Monport Black Laser Marking Spray?

Monport’s Black Laser Marking Spray is a game-changer for anyone looking to create durable, precise, and high-quality laser marks on metal surfaces. Its compatibility with CO2 lasers, combined with its easy application and cleanup, makes it an indispensable tool for professionals and hobbyists alike. With Monport Black Laser Marking Spray, you can be confident that your metal engraving projects will have permanent, high-contrast results every time.

Add this versatile spray to your toolkit today and experience effortless laser marking like never before!

Conclusion: Unleash Your Laser Engrave Wood Creativity with Confidence

Laser engrave wood opens a world of possibilities for woodworkers of all skill levels. With its exceptional precision, speed, and versatility, this innovative technology allows you to create unique and stunning pieces that will impress. The Monport Desktop CO2 Laser 40W, along with a wooden cut machine, is a user-friendly and powerful tool that empowers you to bring your engraver on wood creative visions to life.

Ready to embark on your laser engraving journey? Visit our website today to learn more about the Monport Desktop CO2 Laser 40W and explore the countless possibilities it offers. We're confident that with this remarkable laser engraver at your disposal, you'll be able to elevate your woodworking projects to a whole new level. Let your creativity take flight and discover the magic of laser engrave wood and the power of a wooden cut machine!