Leather laser engraving has revolutionized the art of personalization and customization, and one material that lends itself beautifully to this technique is leather. With its natural texture and rich character, engraving leather can add a touch of elegance to various products, especially when paired with black laser marking spray to enhance the contrast and detail of the designs.However, achieving the desired results requires a deep understanding of the laser CO2 engraving settings specific to different leather types. In this comprehensive blog, we will guide you through the process of determining the laser CO2 laser leather engraving settings for various leather types, to create stunning laser CO2 engraved leather projects.

Read More : Laser Engraving & Cutting Leather

Understanding Laser Leather Engraving

Before diving into the intricacies of laser CO2 engraving settings, it's crucial to understand how lasers interact with leather. When a CO2 laser beam makes contact with leather, it heats and vaporizes the surface, creating permanent marks. Proper settings are essential to control the depth and quality of the engraving. This precision is what makes laser etching on leather such a popular choice for everything from luxury goods to handmade gifts.

Determining Leather Thickness and Type

To get the best results from laser etching on leather, start by accurately measuring the leather's thickness. Leather varies widely—from thin, flexible sheets to thick, rugged hides. Use a caliper or reference the material’s specifications.

Leather types like full-grain, top-grain, genuine leather, and suede each react differently to laser processing. For instance, full-grain leather may need higher power levels, while suede—being more delicate—requires gentler settings. Understanding these differences is key to mastering laser etching on leather.

Testing and Calibration

Never skip test runs before your final project. Cut small leather samples that match the project material and experiment with various power, speed, and frequency settings. This step is critical for fine-tuning your setup for successful laser etching on leather. It helps you avoid mistakes and ensures clean, high-quality results.

Laser Power and Speed

Two critical laser engraving settings to consider are power and speed. Power refers to the energy output of the laser, while speed determines the rate at which the laser moves across the leather surface. Finding the right balance between power and speed is crucial to achieve the desired engraving results.

For lighter, thinner leathers or intricate designs, it's typically recommended to use lower laser power settings to avoid overburning or scorching the material. Higher laser power settings are often necessary for thicker, more durable leathers to ensure a deep and prominent engraving.

Speed settings also play a significant role on leather laser engraving. Faster speeds may result in lighter engraving, while slower speeds allow the laser to spend more time on each area, resulting in deeper engraving. Experimentation and test runs are key to finding the ideal power and speed settings for your specific leather type and design.

DPI (Dots Per Inch)

DPI, or dots per inch, refers to the number of laser points per inch that are used to create the engraving. Higher DPI settings result in greater detail and clarity, while lower DPI settings create a more rough and grainy engraving. When working with leather, a balance must be struck between resolution and engraving time. Higher DPI settings tend to engrave more slowly, so consider the complexity of your design and the time constraints you have.

Focus and Z-Axis Adjustment

Achieving optimal focus is essential for a successful leather engraving. The focal point is determined by adjusting the laser's focal lens, ensuring that the laser beam is concentrated at the right point within the leather's thickness. A well-focused laser beam produces sharp, clean lines, while an improperly focused beam may result in blurry or inconsistent engraving.

Additionally, if your laser engraver has a Z-axis, adjust the position to match the leather surface's distance from the laser source. This adjustment helps maintain consistent engraving depth throughout the entire surface.

Post-Processing Considerations

After laser engraving on leather, it's important to give consideration to post-processing measures. Leather tends to produce a slight burn residue known as "lash." Use a soft brush or compressed air to remove any loose residue from the engraved area. If desired, leather can be treated with leather conditioners or finishes to enhance its appearance or provide additional protection.

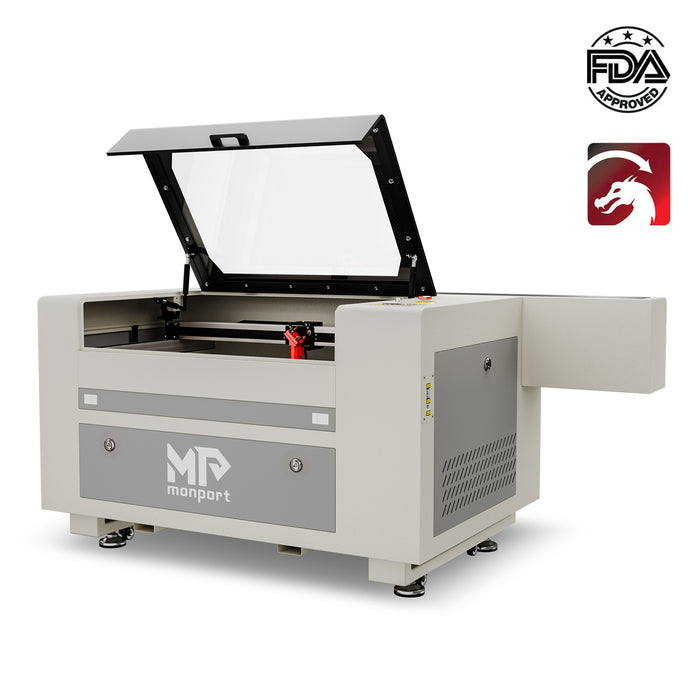

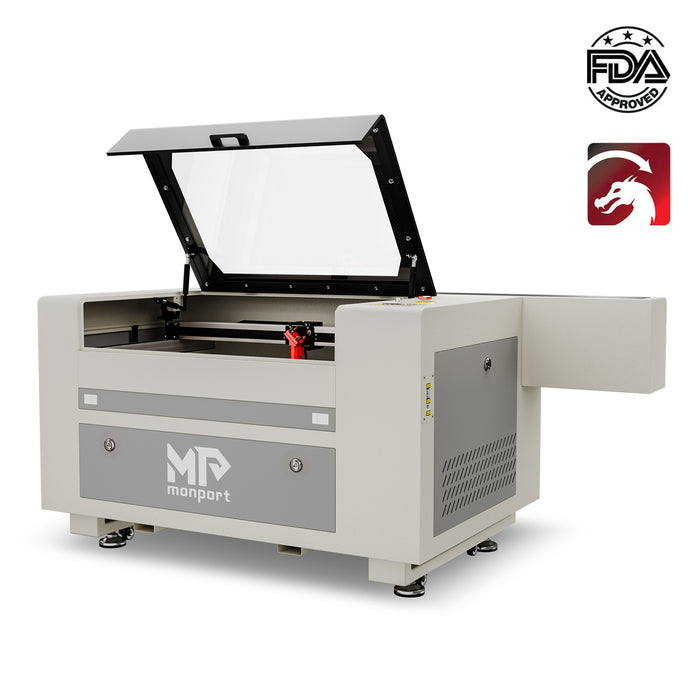

Monport 80W CO2 Laser: Experiencee Laser Engraving Like No Other

In the realm of laser engraving, the Monport 80W CO2 Laser emerges as the ultimate choice for laser engraving enthusiasts. With its exceptional Laser Power and Speed, DPI (Dots Per Inch) capabilities, and precise Focus and Z-Axis Adjustment, the Monport 80W CO2 Laser enables users to achieve outstanding engraving results

Optimized Laser Power and Speed

The Monport 80W CO2 Laser boasts an optimized laser power and speed combination, allowing users to achieve remarkable leather laser engraving results on various materials. The 80W power output provides sufficient energy to cleanly cut through and engrave a wide range of materials, including wood, acrylic, leather, and more. Whether you're tackling intricate designs or large-scale projects, the Monport 80W CO2 Laser delivers both power and speed, ensuring efficiency and precision. The ability to adjust the laser power and speed settings allows users to fine-tune their engraving process to match their desired outcome.

Enhanced DPI (Dots Per Inch) Capabilities

To achieve intricate and detailed engravings, high DPI settings are essential. The Monport 80W CO2 Laser offers enhanced DPI capabilities, providing users with superior engraving depth and clarity. Dots Per Inch refers to the number of laser points used to create each inch of the engraving. Higher DPI settings result in finer details and smoother curves, resulting in stunningly detailed engravings. Whether you're engraving intricate patterns or reproducing fine artwork, the Monport 80W CO2 Laser's high DPI capabilities ensure exceptional quality.

Precise Focus and Z-Axis Adjustment

Achieving precise focus is paramount in laser engraving. The Monport 80W CO2 Laser features a precise focus and Z-Axis adjustment system, enabling users to maintain consistent engraving depth across the entire work surface. The focus adjustment allows for pinpoint accuracy, ensuring sharp and clean lines. Additionally, the Z-Axis adjustment ensures that the laser maintains the correct focal distance regardless of the material's thickness. With these precise adjustments, users can achieve consistent engraving results, regardless of the complexity or thickness of the material.

Versatility and Compatibility

The Monport 80W CO2 Laser is designed to accommodate a wide range of materials, making it a versatile tool for engraving enthusiasts. From wood and acrylic to leather and glass, this laser engraver can handle diverse materials with ease. The machine's compatibility with different materials is further enhanced by its adjustable laser power and speed, allowing users to optimize settings based on the unique properties and thickness of each material. With the Monport 80W CO2 Laser, creative possibilities are virtually limitless.

User-Friendly Interface

Operating the Monport 80W CO2 Laser is a seamless experience, thanks to its user-friendly interface. The engraver is equipped with an intuitive control panel and a high-resolution display, providing users with a clear overview of the engraving parameters, artwork layout, and process status. The user-friendly interface ensures that even novice users can quickly grasp the engraving process and navigate through settings with ease. With its comprehensive software and easy-to-use controls, the Monport 80W CO2 Laser delivers a hassle-free engraving experience.

Conclusion

Laser engraving offers a world of creative possibilities when working with leather. Understanding and fine-tuning laser engraving settings for different leather types is essential for achieving exceptional results. By considering factors such as leather thickness, type, and conducting thorough testing, you can optimize power, speed, DPI, focus, and z-axis adjustments to accomplish precise engraving. The Monport 80W CO2 Laser checks all the boxes with its optimized Laser Power and Speed, enhanced DPI capabilities, precise Focus and Z-Axis Adjustment, and versatility. Whether you're a passionate hobbyist or a professional engraver, the Monport 80W CO2 Laser provides the perfect combination of power, precision, and ease of use. Embrace this exceptional machine and witness your creative visions come to life with remarkable precision and detail, especially when using black laser marking spray for bold, high-contrast designs. Visit the Monport website for more helpful leather laser engraving guides and tips to your laser engraving journey!