Metal laser marking spray has revolutionized the way we personalize and identify products. By combining the precision of laser technology with the versatility of metal laser engraving spray, you can achieve stunning and durable results. This guide will delve into the intricacies of this process and explore how a 60 watt fiber laser, such as the Monport GI60, can elevate your marking capabilities.

Monport GI 60W Integrated MOPA Fiber Laser Engraver & Marking Machine with Electric Lifting

Understanding Metal Laser Engraving Spray

Metal laser marking spray is a specialized coating designed to enhance the visibility and contrast of laser-engraved markings on metal surfaces. Laser marking spray typically contains pigments or other additives that react with the laser beam to create a distinct mark. This spray can be applied to the metal before or after the engraving process, depending on the desired effect.

Key benefits of using metal laser marking spray:

- Enhanced visibility: Improves the contrast and legibility of the engraved markings.

- Durability: Provides a protective layer that helps prevent wear and corrosion.

- Customization: Laser marking spray offers a wide range of colors and finishes to match your branding or design requirements.

The Role of a 60 Watt Fiber Laser in Metal Marking

A 60-watt fiber laser, like the Monport GI60, is the ideal tool for precise and efficient metal marking. Its high power output and advanced features enable you to create intricate designs and durable markings with ease.

Key features of the Monport GI60 Fiber Laser for metal marking:

- Full Color Marking: Produces vibrant and detailed markings on various metals.

- Integrated Innovative Design: Offers a compact and user-friendly experience.

- Electric Lifting Focus: Ensures accurate focus for consistent results.

- LightBurn Compatibility: Seamless integration with popular design software.

- Industry-leading Heat Dissipation: Maintains optimal performance during extended use.

Machine Guide: Optimizing Laser Parameters for Metal Marking

To achieve optimal results when using metal laser marking spray, it's essential to configure the laser machine with the correct parameters. Here are some general guidelines:

- Power: Adjust the laser power based on the thickness of the metal and the desired marking depth.

- Speed: Experiment with different speeds to find the optimal balance between marking quality and efficiency.

- Frequency: For color marking, adjust the laser frequency to achieve the desired color variations.

- Focus: Ensure the laser beam is focused precisely on the metal surface for accurate markings.

Combining Metal Marking Spray with Laser Engraving

To achieve the best possible results, consider the following steps:

- Clean the metal surface: Prepare the metal surface by removing any dirt, grease, or contaminants.

- Apply metal marking spray: Evenly coat the metal surface with the chosen spray. Allow it to dry completely.

- Laser engraving: Use the laser machine to create your desired markings on the sprayed surface.

- Post-treatment: Depending on the laser marking spray and application, you may need to apply a protective coating or clear coat.

By combining metal marking spray with laser engraving, you can create high-contrast, durable, and visually appealing markings on a variety of metal surfaces. Experiment with different spray types, laser parameters, and design elements to achieve your desired results.

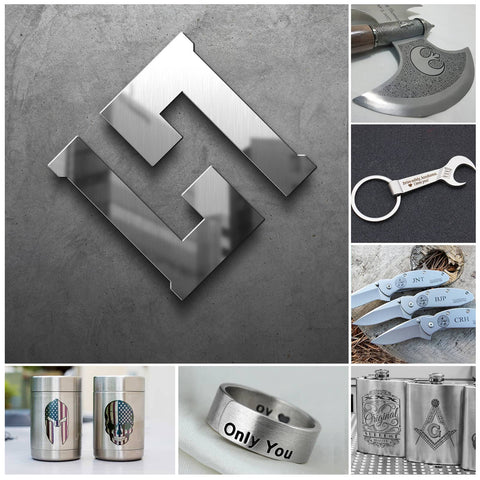

Ideas for Metal Laser Marking

Metal laser marking offers a vast array of creative possibilities. Here are some ideas to inspire your projects:

- Product identification: Engrave serial numbers, barcodes, or QR codes for tracking and inventory management.

- Branding: Create customized logos and designs to enhance product identity.

- Decorative elements: Add intricate patterns and designs to metal surfaces for aesthetic appeal.

- Personalization: Engrave names, initials, or special messages for a unique touch.

- Industrial applications: Mark metal components for assembly and maintenance purposes.

By combining the precision of laser engraving with the versatility of metal laser marking spray, you can create a wide range of applications.

Conclusion

By combining the power of a 60-watt fiber laser with the versatility of metal laser marking spray, you can achieve exceptional results in metal marking. The Monport GI60 Fiber Laser, with its advanced features, is a valuable tool for businesses looking to enhance their product branding and identification.