Whether you're a seasoned engraver or just diving into the world of laser cutting, your success depends on one thing: how well you maintain your machine. A powerful desktop CO2 laser machine like the Monport Mega offers blazing speed, unmatched precision, and smart automation—but even the best hardware needs proper care to perform at its peak.

To help you get the most out of your equipment, we’ve created this all-in-one guide to CO2 laser engraver maintenance, complete with a detailed Mega Laser Head Cleaning and Maintenance Guide. Follow these expert tips to protect your investment, ensure consistent engraving results, and extend the lifespan of your desktop CO2 laser machine.

Why CO2 Laser Engraver Maintenance Matters

Routine CO2 laser engraver maintenance helps:

-

Maintain cutting and engraving precision

-

Prevent costly repairs or replacement

-

Ensure safety in your workspace

-

Prolong the operational life of your desktop CO₂ laser machine

-

Keep production efficient and downtime minimal

Skipping maintenance might save time in the short term, but it often leads to bigger, costlier problems down the line.

Suggested Maintenance Schedule for Monport Mega

To streamline your CO₂ laser engraver maintenance, follow this usage-based guide:

-

Engraving Duration ≥ 24 hours → Perform full component cleaning

-

Cutting Duration ≥ 4 hours → Perform full component cleaning

This frequency ensures optimal function without overloading or contaminating your desktop CO₂ laser machine.

Step-by-Step: Mega Laser Head Cleaning and Maintenance Guide

⚠️ Important: Always disconnect your machine from the power supply before performing maintenance.

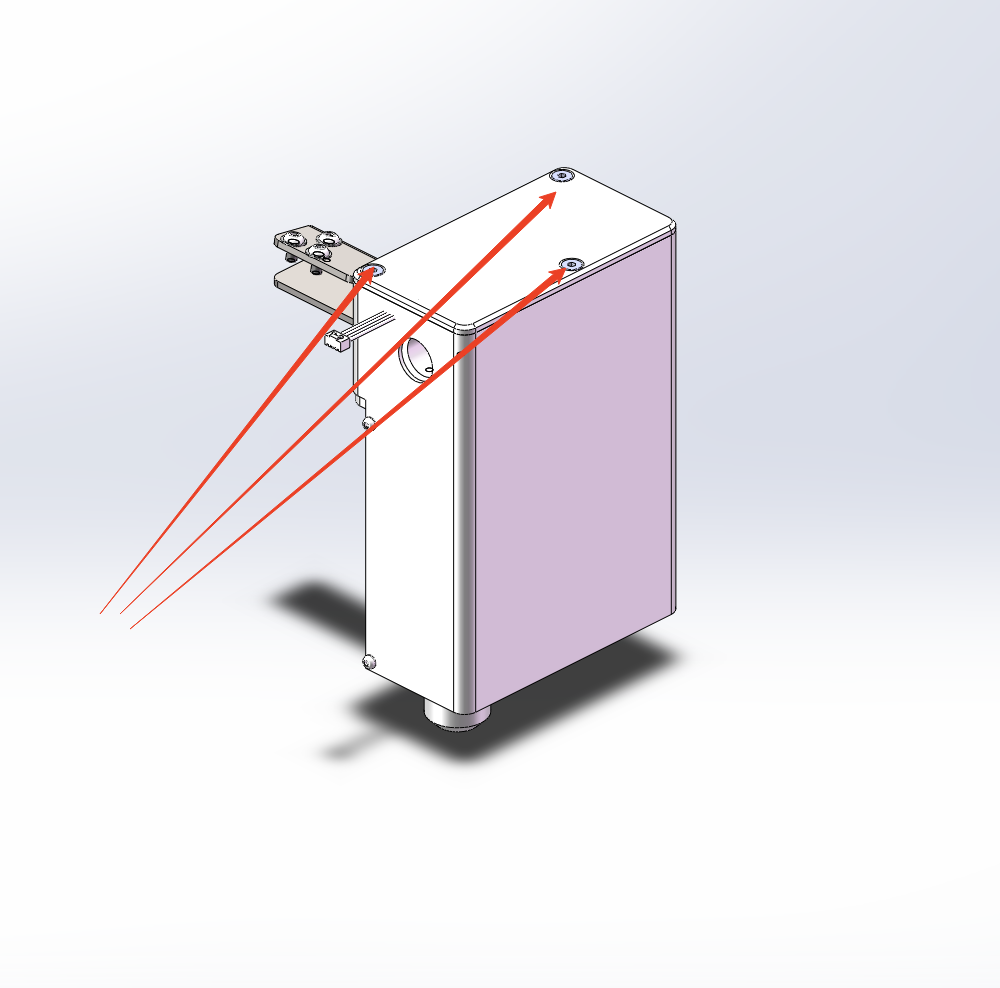

1. Disassembly of laser head housing

1) Remove the screws on the top cover and take off the top cover

2) Remove the screws on the side of the cover and slide it upwards to remove it.

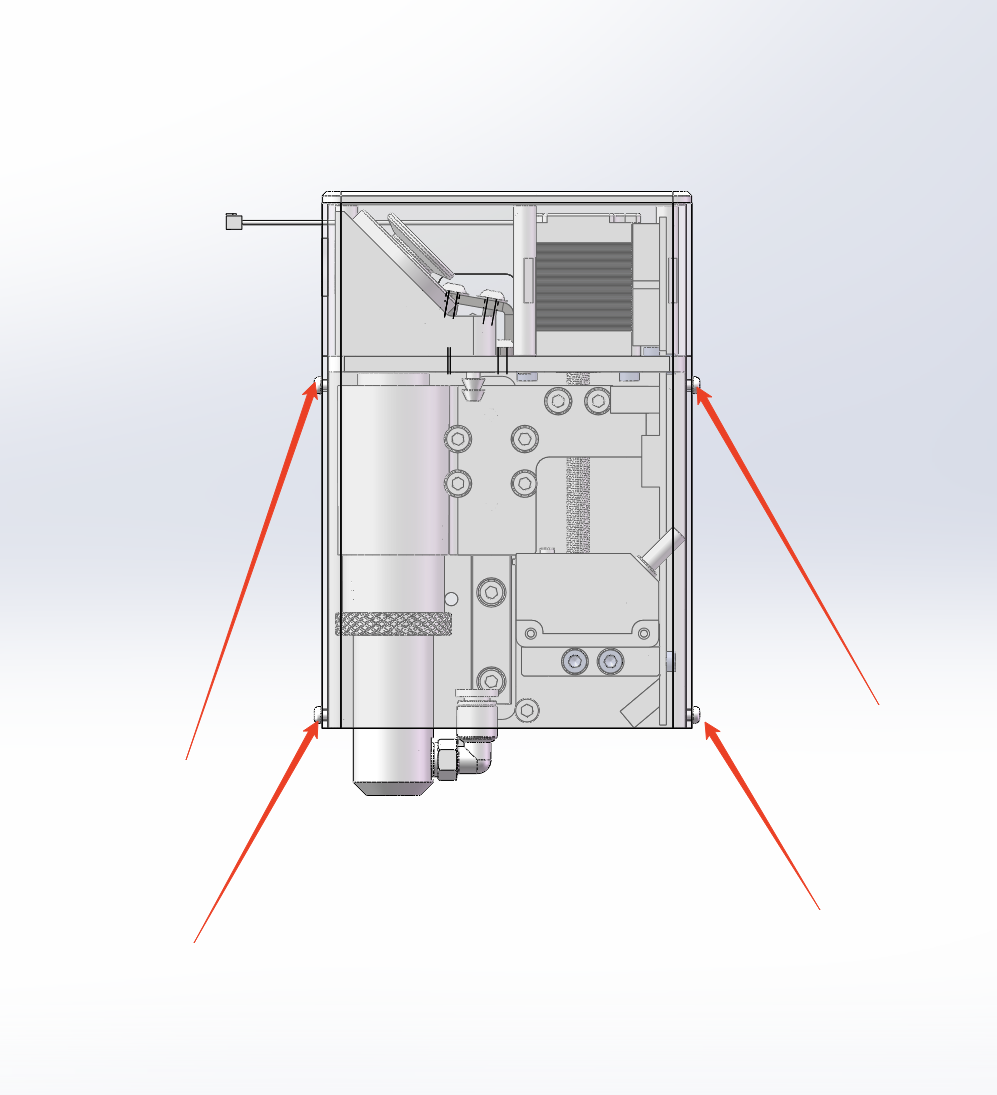

2. Disassembly of Laser Head Components

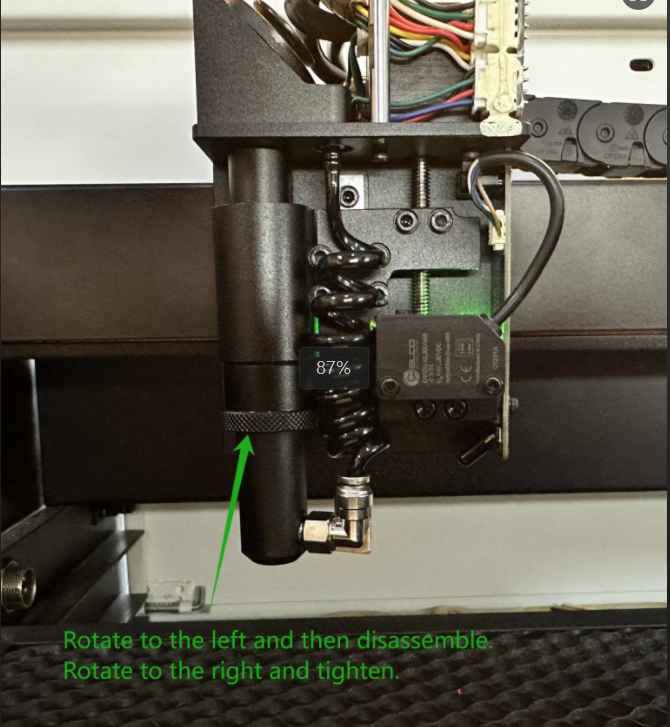

1) Remove the air nozzle component of the laser head and place it properly on a static-dissipative and clean work surface.

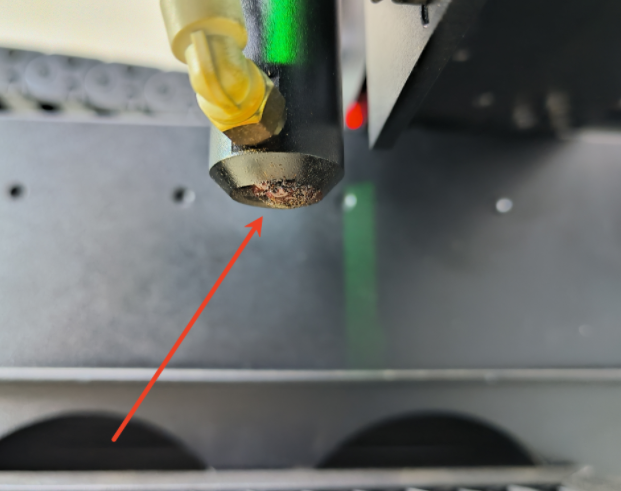

2) Remove the focusing lens mounting base and clean the base with alcohol and a dust-free cloth.

Clean the stains on the laser head. (It is necessary to clean it daily to prevent blockage caused by prolonged use.)

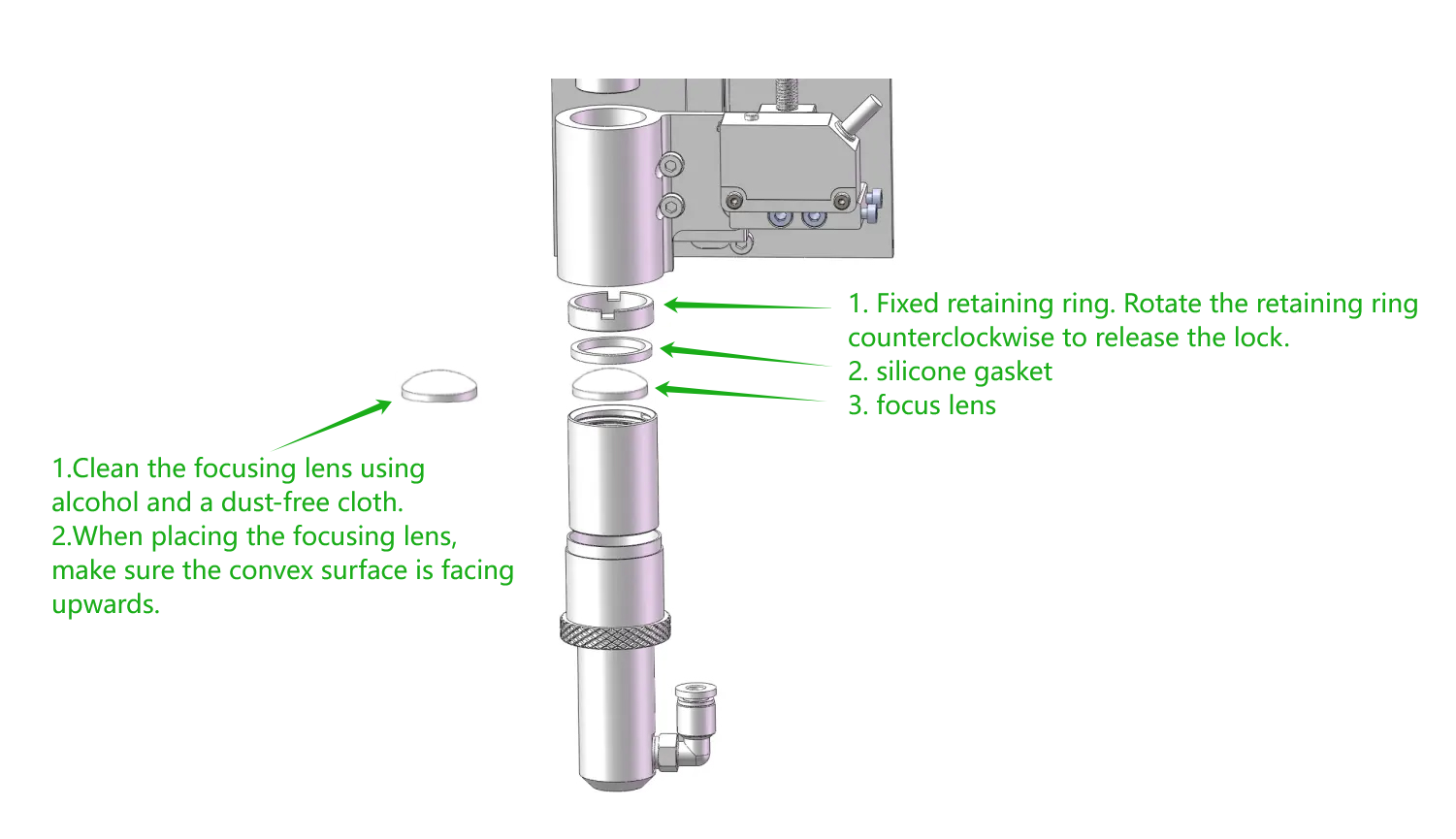

3. Lens disassembly

1) Remove the silicone sealing gasket and the focusing lens assembly one by one. Pay attention to recording the disassembly sequence of each component.

4. Cleaning Operations

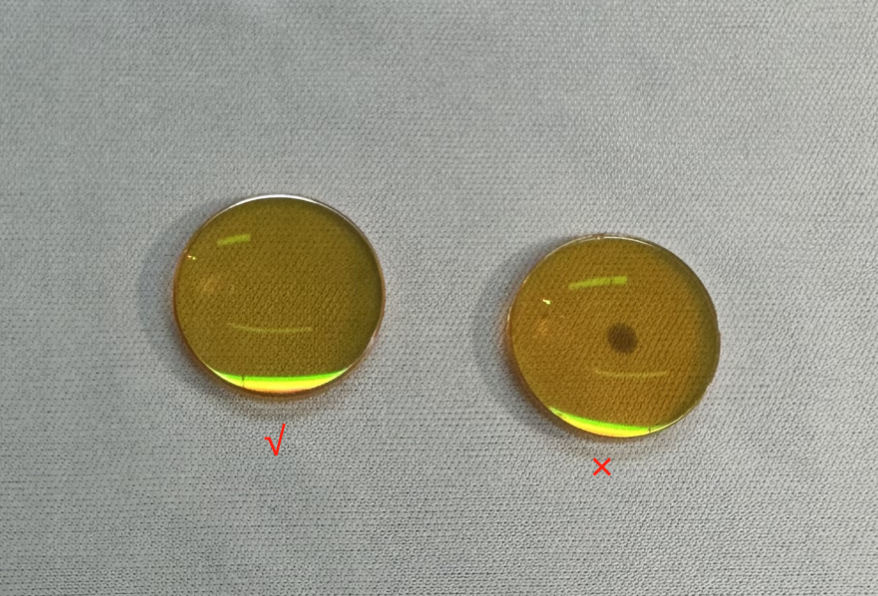

1) Regularly clean the focusing lens with alcohol and a lint-free cloth.

2) Wipe the lens radially in a single direction (do not rotate while wiping).

3) Check the integrity of the lens surface and confirm there are no scratches or burn marks.

5. Assembly and Reset

1) Ensure that the convex surface of the focusing lens is facing upwards.

2) Install the sealing components in reverse order according to the original disassembly sequence.

Notes:

● Avoid touching the focusing mirror surface with bare hands.

● The working environment should be kept clean.

Weekly and Monthly Maintenance Checklist

Weekly Tasks

-

Align laser path using the Monport Mega’s 5-minute alignment system.

-

Check air duct system for clogs or dust build-up.

-

Inspect air assist and filters.

Monthly Tasks

-

Lubricate guide rails and Z-axis.

-

Examine the water-cooling or airflow systems.

-

Test all safety sensors, including fire detection and enclosure lock.

This maintenance routine ensures your desktop CO₂ laser machine stays fast, safe, and accurate—all while reducing the chance of unexpected breakdowns.

Best Practices for Long-Term Laser Performance

To maximize the life and performance of your desktop CO₂ laser machine, follow these advanced tips:

Use Auto-Focus Strategically

The Monport Mega's auto-focus feature automatically adjusts the laser for material thickness, reducing setup errors and wear on the lens.

Maintain a Clean Work Environment

The enclosed track design and air duct system work together to prevent dust accumulation. Still, regular vacuuming around the machine enhances airflow and cooling.

Rely on Visual Adjustments

Thanks to the integrated visual light adjustment system, you can quickly position your material without messy masking tape.

Utilize Smart Batch Engraving

The Monport Mega’s high precision vision recognition allows batch engraving and curvature adaptation, which reduces repetitive setup and wear on moving components.

Why Monport Mega Sets the Standard in Desktop CO₂ Laser Machines

With its 70W power, ultra-fast 600mm/s speed, and autofocus precision, the Monport Mega isn't just a machine—it’s an intelligent workhorse. Its advanced features include:

-

Flame detection & extinguishing system

-

8MP ultra-wide-angle camera for pattern replication

-

Expansion-ready design for cylindrical engraving

-

Noise control below 65dB

-

Class 1 Laser Compliance with Class 4 Certification

Its enclosed guide rail, smart air duct system, and automated safety measures make it one of the safest and most efficient desktop CO₂ laser machines on the market.

Frequently Asked Questions: CO2 Laser Engraver Maintenance

Q1: How often should I clean my desktop CO2 laser machine?

It depends on usage. If you engrave for more than 24 hours or cut for over 4 hours, it’s recommended to perform a full maintenance routine. Daily cleaning of the laser head is also encouraged to prevent buildup.

Q2: What’s the best way to clean the focusing lens?

Use high-purity alcohol and a lint-free cloth. Always wipe in a radial direction without rotating the cloth, and avoid touching the lens surface with bare hands to prevent smudges or scratches.

Q3: Can I use any air compressor for the air assist system?

It’s best to use the built-in air assist included with the Monport Mega, as it’s calibrated for optimal pressure and performance. Using a third-party compressor may require pressure adjustments and could void warranties.

Q4: What happens if I skip maintenance?

Skipping routine CO₂ laser engraver maintenance can result in:

-

Poor engraving quality

-

Inconsistent focus or beam path

-

Increased risk of damage to the lens or nozzle

-

Overheating and safety risks

-

Shortened lifespan of your desktop CO₂ laser machine

Q5: Is the Monport Mega suitable for beginners?

Yes! The Monport Mega is designed with both professionals and hobbyists in mind. Its intelligent features—like autofocus, visual alignment, enclosed safety design, and flame detection—make it incredibly user-friendly and safe to operate.

Final Thoughts: Protect Your Investment

Your desktop CO₂ laser machine is a powerful tool—and just like any precision device, it requires regular care to stay in top form. By following the expert tips in this CO₂ laser engraver maintenance guide, including our detailed Mega Laser Head Cleaning walkthrough, you can keep your system performing flawlessly for years to come.

The Monport Mega makes it easier than ever to maintain, thanks to its user-friendly design, intelligent systems, and rugged build. Invest in your machine’s health now—and enjoy the long-term payoff in precision, safety, and reliability.

Ready to engrave smarter, cleaner, and faster? Discover the full potential of the Monport Mega 70W—your ultimate desktop CO2 laser machine for professional-grade results.

Start engraving smarter. Choose Monport Mega.