A laser engraver for aluminum offers unmatched precision, speed, and versatility for marking and engraving aluminum surfaces. From industrial parts to personalized gifts, mastering aluminum laser engraving ensures professional, long-lasting results. This guide explores the benefits, applications, and best practices for using a laser engraver for aluminum.

Benefits of Fiber Laser Engraving on Aluminum

Precision and Detail

A laser engraver for aluminum produces fine, intricate designs with exceptional accuracy. Ideal for:

-

Logos and branding

-

Serial numbers and barcodes

-

QR codes and industrial markings

Durability

Fiber laser engravings are permanent, resistant to wear, corrosion, and extreme temperatures, making a laser engraver for aluminum perfect for long-term applications.

Speed and Efficiency

High-speed operation allows rapid engraving, ideal for high-volume production and industrial settings.

Versatility

Engrave anodized, painted, or coated aluminum with consistent results.

Low Maintenance

Fiber laser machines require minimal upkeep, reducing downtime and operational costs.

Applications of a Laser Engraver for Aluminum

A laser engraver for aluminum is widely used across industries:

-

Industrial Components: Serial numbers, barcodes, and QR codes

-

Aerospace & Automotive: Marking specifications and logos

-

Electronics: Engraving circuit patterns and parts

-

Custom Gifts & Awards: Plaques, trophies, and personalized aluminum items

-

Signage & Decorative Items: Intricate designs for panels and signs

Choosing the Right Fiber Laser Marking Engraving Machine

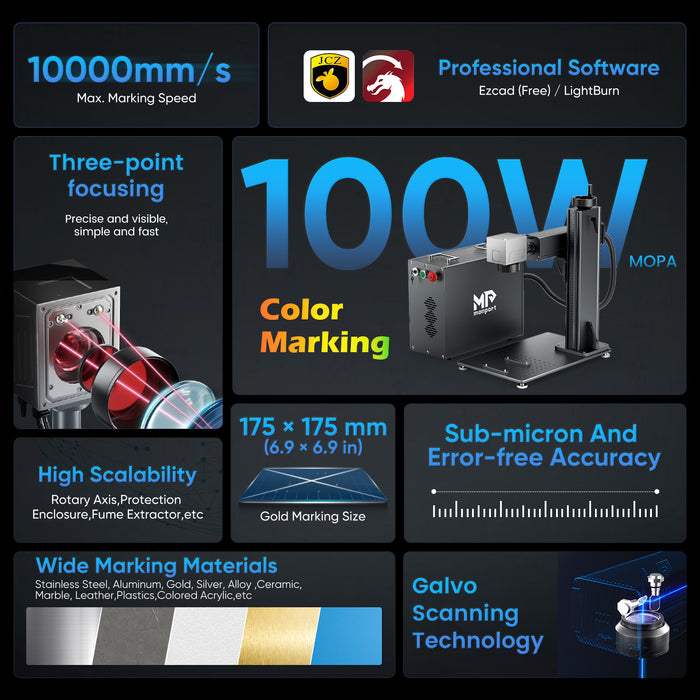

Monport GPro 100W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!

When selecting a fiber laser marking engraving machine, consider the following factors to ensure you choose the best equipment for your needs:

-

Power Output: 20W–50W is sufficient for most aluminum engraving. Higher wattage allows faster, deeper engravings.

-

Marking Area: Choose a machine that fits your typical workpieces (100x100mm to 300x300mm).

-

Software Compatibility: Look for user-friendly software like EzCad for design and control.

-

Cooling System: Air cooling for low-power units; water cooling for higher-power machines.

-

Build Quality: Sturdy construction ensures precision and longevity.

Experience Precision and Power with Monport Black Laser Marking Spray

Unlock the full potential of your CO2 laser engraver with Monport’s black laser marking spray—your go-to solution for achieving crisp, high-contrast marks on metal surfaces. This 14 oz. aerosol can is engineered for simplicity and performance: just shake, spray, and engrave. The black laser marking spray delivers a deep, permanent mark on metals like aluminum, stainless steel, and brass, making it ideal for customizing jewelry, labeling tools, or decorating glassware. With an anti-clog nozzle and nanoparticle formula, you get an even spray that dries in just five minutes. Designed specifically for CO2 lasers of 25 watts and above, this alcohol-free formula ensures both safety and efficiency. Whether you’re personalizing a gift or producing serial numbers, Monport’s black laser marking spray ensures a flawless finish every time. Easy to apply, resistant to heat, and simple to clean—just rinse and reveal your design. If you're looking to elevate your laser engraving game, there's no better companion than this reliable black laser marking spray from Monport.

FAQs: Laser Engraver for Aluminum

Q1: Can I engrave anodized aluminum?

A1: Yes, a fiber laser engraver for aluminum works effectively on anodized surfaces, producing high-contrast marks.

Q2: Do I need a high-power laser for deep engraving?

A2: For deeper marks, higher wattage machines are recommended, but standard 20–50W units are sufficient for most tasks.

Q3: Is black laser marking spray necessary?

A3: While not always required, it enhances contrast on lighter aluminum and produces professional-looking results.

Q4: Can I use a fiber laser engraver for other metals?

A4: Yes, including stainless steel, brass, and copper, making the machine versatile beyond aluminum.

Q5: How do I maintain my laser engraver for aluminum?

A5: Keep optics clean, ensure proper cooling, and follow manufacturer maintenance schedules to prolong lifespan.

Conclusion

A laser engraver for aluminum provides precision, durability, and efficiency for industrial, decorative, and personalized applications. Understanding its benefits, applications, and machine specifications ensures professional, long-lasting results. Investing in a high-quality fiber laser engraver elevates your production capabilities and opens opportunities for detailed aluminum engraving projects.

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!