Fiber laser marking technology has revolutionized the engraving industry with its precision, efficiency, and versatility. Among the various types of fiber laser cutting machine, MOPA (Master Oscillator Power Amplifier) fiber lasers stand out for their ability to perform color marking, a feature that has opened new horizons for customization and branding. This guide delves into the intricacies of MOPA fiber laser marking, the capabilities of color fiber laser marking machines, and why Monport fiber laser cutting machines are the best laser engraver choice for your engraving needs, especially for color laser marking and color fill engraving.

Understanding MOPA Fiber Laser Marking

What is MOPA Fiber Laser?

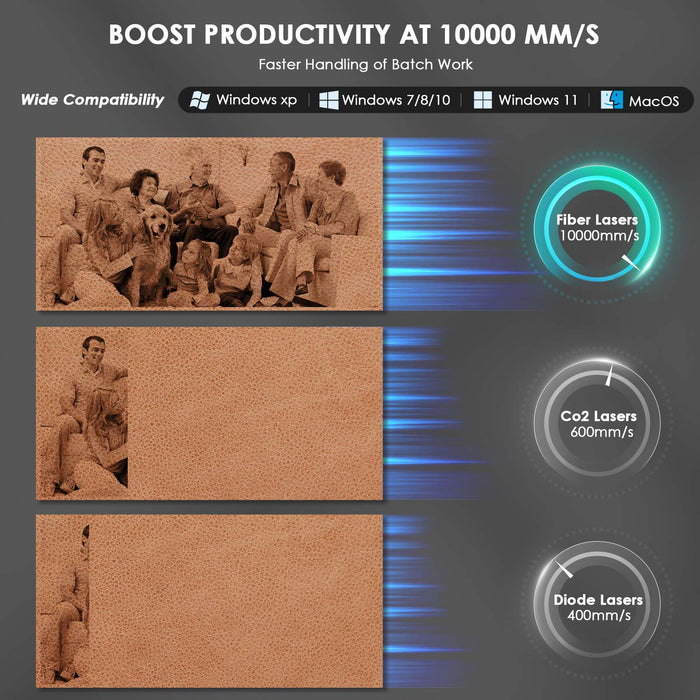

MOPA fiber lasers differ from traditional continuous wave fiber lasers in that they allow for more control over the pulse duration and frequency. This control enables MOPA lasers to perform a variety of tasks that are difficult or impossible for other types of laser cutting machines. When looking for the best laser engraver, MOPA lasers offer outstanding flexibility and performance. They are ideal for applications requiring precise color laser marking and color fill engraving.

Advantages of MOPA Fiber Laser Marking

- Versatility: MOPA lasers can mark a wide range of materials, including metals, plastics, and ceramics.

- Precision: They offer high precision in engraving, suitable for intricate designs and fine details, making them the best laser engraver for detailed work.

- Color Marking: One of the standout features of MOPA fiber lasers is their ability to create color markings on stainless steel and titanium, elevating their value as the best laser engraver for custom branding through color laser marking and color fill engraving.

- Adjustable Pulse Duration: This allows for control over the marking process, providing better results with your best laser engraver on various materials.

Exploring Color Fiber Laser Marking

How Color Fiber Laser Marking Works

Color laser marking utilizes the MOPA laser’s ability to adjust pulse durations to manipulate the surface layer of the material, creating different colors through controlled oxidation. This process requires precise settings of your best laser engraver and high-quality equipment to achieve consistent and vibrant results.

Applications of Color Laser Marking

- Branding: Adding color logos or labels to products for enhanced brand recognition using the best laser engraver.

- Personalization: Creating personalized gifts and items with colorful engravings.

- Industrial Marking: Marking parts with colored codes for easy identification.

Monport Fiber Laser Machines: The Ultimate Choice for Color Laser Engraving

Why Choose Monport Fiber Laser Machines?

Monport is renowned for its high-quality fiber laser machines that are engineered for precision, efficiency, and versatility, particularly in color laser marking and color fill engraving. Here’s why Monport stands out as the best laser engraver:

Advanced Technology: Monport machines incorporate the latest advancements in MOPA fiber laser technology, ensuring top-notch performance and making them the best laser engraver.

User-Friendly Interface: Designed with the user in mind, Monport machines are easy to operate, even for beginners.

Durability and Reliability: Built to last, Monport laser engravers are made with high-quality components that ensure long-term reliability.

Support and Service: Monport offers excellent customer support and after-sales service, ensuring you get the most out of your investment.

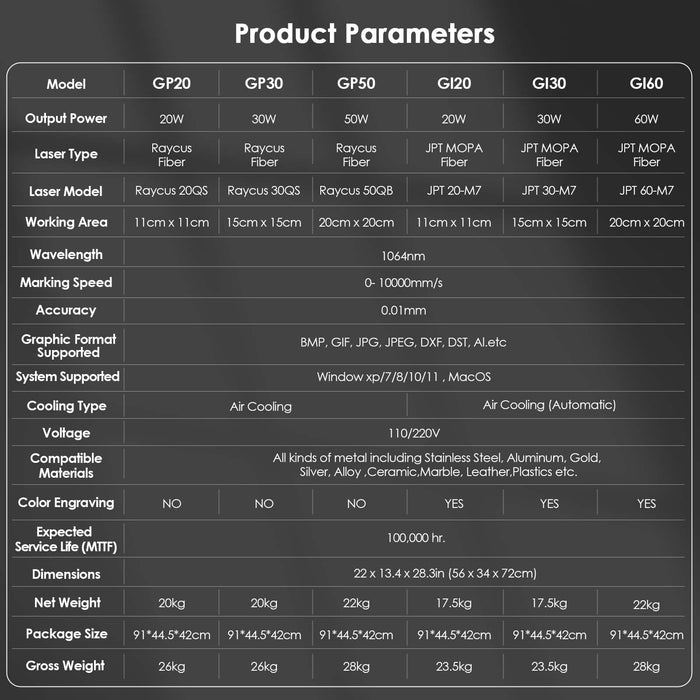

Monport Fiber Laser Machine Models

Monport offers a range of fiber laser machines tailored to various needs. Here are some of their popular models:

- Monport GPro Series MOPA: This machine is equipped with a powerful 30W to 100W laser source, ideal for both engraving and cutting. Its MOPA technology allows for vibrant color marking on stainless steel and intricate designs on other materials.

- Monport GA Series MOPA: Known for its one-click autofocus system and ±90° adjustable arm, this model ensures consistent engraving results and opens up creative possibilities for curved surfaces.

- Monport GQ Series: Compact and powerful, this machine delivers precise engraving at speeds of up to 7000mm/s, making it ideal for detailed work on metals and plastics.

Getting Started with MOPA Fiber Laser Marking

Setting Up Your Monport Laser Machine

- Installation: Follow the detailed manual provided by Monport to set up your machine. Ensure it’s placed in a well-ventilated area with stable power supply.

- Software Installation: Install the design software compatible with your Monport laser machine. CorelDRAW or Adobe Illustrator are commonly used for creating designs.

- Calibration: Calibrate the machine to ensure precision. Monport machines come with easy-to-follow calibration instructions.

Key Settings for Color Laser Marking

- Pulse Duration: Adjust the pulse duration to control the heat and achieve the desired color on stainless steel.

- Frequency: Set the appropriate frequency to match the material being engraved.

- Power and Speed: Fine-tune the power and speed settings to ensure clear and vibrant markings.

Tips for Successful Color Laser Marking

- Material Preparation: Clean the surface of the material to remove any contaminants that could affect the engraving quality.

- Test Runs: Perform test engravings on a sample piece to fine-tune your settings before working on the final product.

- Maintenance: Regularly maintain your Monport laser machine by cleaning the lens and checking for any signs of wear.

Achieve Precision and Durability with Monport Black Laser Marking Spray

Monport black laser marking spray is the ultimate solution for achieving high-contrast, permanent black markings on metals like aluminum, stainless steel, and brass. Specifically designed for CO2 laser engraving machines of 25 watts and above, this black laser marking spray ensures deep penetration and long-lasting results. Its advanced anti-clog nozzle provides an even and smooth application, making it easy to achieve consistent, high-quality engravings. The quick-dry formula allows the black laser marking spray to dry in just five minutes, ensuring an efficient workflow. Once engraving is complete, simply rinse off the excess black laser marking spray to reveal sharp, crisp markings with no residue. Whether for customizing jewelry, personalizing glassware, or marking industrial tools, Monport black laser marking spray guarantees exceptional performance and durability.

FAQs

1. What types of laser machines does Monport offer?

Monport provides a diverse range of laser machines, including:

-

CO₂ Laser Engravers: Available in various power levels (e.g., 40W, 60W, 80W, 100W, 130W), suitable for materials like wood, acrylic, leather, and glass.

-

Fiber Laser Engravers: Designed for metal marking and engraving, ideal for industrial applications.

-

Desktop Models: Compact and beginner-friendly options like the 40W and 55W models, perfect for hobbyists and small businesses.

Each machine series caters to different user needs, from entry-level to professional-grade applications.

2. What materials can I engrave or cut with a Monport laser machine?

Monport laser machines are versatile and can work with a wide array of materials:

-

CO₂ Lasers: Suitable for cutting and engraving wood, acrylic, leather, fabric, glass, and certain plastics.

-

Fiber Lasers: Ideal for marking and engraving metals such as stainless steel, aluminum, brass, and copper.

The specific capabilities depend on the machine's power and type.

3. How do I choose between a 60W and an 80W CO₂ laser cutter?

The choice between a 60W and an 80W CO₂ laser cutter depends on your specific needs: (60w vs 80w Laser Cutter: The Ultimate FAQ Guide by Monport Laser)

-

60W Laser: Suitable for thinner materials and detailed engraving tasks.

-

80W Laser: Offers deeper cuts and faster processing speeds, making it better for thicker materials and higher-volume projects.

Consider the materials you plan to work with and the desired production speed when choosing between the two.

4. What software is compatible with Monport laser machines?

Monport laser machines are compatible with several popular design and control software options:

-

LightBurn: A widely used software for designing and controlling laser cutters and engravers.

-

RDWorks: Often used with CO₂ laser machines for creating and managing cutting paths.

These software options allow users to create intricate designs and control the laser's operations effectively.

5. Does Monport offer customer support and training resources?

Yes, Monport provides comprehensive customer support and resources:

-

Technical Support: Available to assist with machine setup, troubleshooting, and maintenance.

-

User Manuals and Guides: Detailed documentation to help users understand and operate their machines.

-

Tutorials and Blogs: Educational content covering various topics, from beginner guides to advanced techniques.

Conclusion

Starting a glass engraving business can be a highly rewarding venture, combining creativity with entrepreneurship. Investing in a high-quality laser engraving machine like those offered by Monport ensures precision, efficiency, and versatility. Monport's advanced technology, user-friendly interface, and excellent customer support make their fiber laser machines the best laser engraver for color laser engraving.

Make your move today, visit Monport, and don’t forget to use BESTMP10 at checkout to claim your special offer. Your next best-selling product line could be just one laser cut away. Click here!

Key Takeaways

- MOPA Fiber Laser: Offers versatility, precision, and color marking capabilities.

- Color Laser Marking: Ideal for branding, personalization, and industrial marking.

- Monport Fiber Laser Machines: Known for their advanced technology, durability, and user-friendly features.

- Getting Started: Proper setup, calibration, and understanding of key settings are essential for successful laser marking.

- Success Tips: Material preparation, test runs, and regular maintenance ensure high-quality results.

Visit the Monport website to explore their range of fiber laser machines and take the first step towards enhancing your engraving business with top-notch color laser marking and color fill engraving capabilities.

ReadMore: Comprehensive Guide to MOPA Fiber Laser Marking and Color Fiber Laser Marking Machines