Can you engrave faux leather? The world of faux leather, also known as synthetic leather, offers a versatile and cost-effective alternative to genuine leather. black laser marking spray. However, "can you engrave faux leather?" remains a continuing question. This guide explores the Monport 100W CO2 Laser as a powerful tool for engraving on leather, including leather laser techniques, delving into settings, price cutters, material compatibility, yag vs co2 laser.and valuable tips to achieve stunning results on engraved on leather. If you're wondering where can you get leather engraved, consider using a Monport 100W CO2 Laser Machine for your projects.

Monport 100W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus and Bracket

Can You Engrave Faux Leather?

Absolutely! The Monport 100W CO2 Laser Machine is perfectly suited for engraving faux leather, creating designs engraved on leather. This price cutters machine's high-efficiency laser beam precisely interacts with the material's surface, creating permanent and clean engravings. Leather laser enthusiasts will appreciate how the machine handles intricate patterns. However, unlike natural leather, faux leather can vary in composition, and understanding these variations is crucial for achieving optimal results on engraved on leather. If you're looking for where can you get leather engraved, consider using a Monport 100W CO2 Laser Machine.

Types of Artificial or Faux Leather Suitable for Laser Cutting and Engraving

Most commercially available faux leather compositions work well with the Monport 100W CO2 Laser Machine. Here are some suitable types: yag vs co2 laser. Leather laser methods can be applied to all these types with proper settings.

- PU (Polyurethane) Leather: This is the most common type of faux leather and is ideal for laser engraving and cutting.

- TPU (Thermoplastic Polyurethane) Leather: TPU offers slightly more durability and flexibility compared to PU leather and can be used for engraving and cutting with proper settings.

- Bio-PU Leather: This eco-friendly alternative to PU leather is also compatible with laser engraving.

Important Note: Always avoid faux leather made with PVC (polyvinyl chloride) as the laser beam can interact with it to produce harmful fumes.

How to Use a Laser Machine to Engrave and Cut Artificial Faux Leather

The Monport 100W CO2 Laser Machine makes engraving and cutting artificial leather a straightforward process. Here's a general overview of a laser price cutters: yag vs co2 laser.

1. Design Preparation: Create your desired design using graphic design software compatible with your laser engraver. Ensure the design is optimized for leather laser engraving or cutting, depending on your project.

2. Material Selection and Preparation: Choose a suitable faux leather material (see next section for compatible types) and cut it to the desired size. Clean the surface of the faux leather with a soft cloth to remove any dust or debris. yag vs co2 laser

3. Machine Settings: Import your design into the laser engraving software and adjust the laser power, speed, and focus settings based on the material thickness and desired outcome. Leather laser professionals often recommend test engravings on scrap material to achieve optimal results.

4. Positioning and Securing: Secure the faux leather flat onto the workbed of the laser machine using clamps or positioning tape. Ensure the design is positioned correctly for engraving or cutting.

5. Engraving or Cutting: Once settings are confirmed and the material is secured, initiate the engraving or cutting process. The laser beam will interact with the faux leather, creating permanent and precise engravings or clean cuts along the designated paths for engraved on leather. Leather laser results are often admired for their precision. If you're looking for where can you get leather engraved, consider using a Monport 100W CO2 Laser Machine.

6. Post-Processing: After engraving or cutting, gently remove any residual debris from the engraved or cut area using a soft brush or compressed air. Avoid using harsh chemicals or abrasive materials that might damage the faux leather.

Settings, Speed & Power: Optimizing Your Faux Leather Engraving Process

The ideal laser settings for engraving faux leather depend on several factors, including the material's thickness, desired engraving depth, and level of detail. However, here's a general starting point for experimentation: yag vs co2 laser.

- Laser Power: Begin with a lower laser power setting (around 30% - 50% of the machine's maximum power) and gradually increase it if needed during your test engravings. Excessive power can burn or melt the faux leather.

- Speed: Start with a slower engraving speed (around 200mm/s - 400mm/s) for intricate designs or deeper engravings. Higher speeds are suitable for shallow engravings or simpler patterns.

- Focus: Ensure the laser beam is properly focused on the surface of the faux leather. This ensures clean and precise engraving lines.

Tips and Tricks for Flawless Faux Engraved Leather

- Test Different Settings: Don't hesitate to experiment with various power, speed, and focus settings on your scrap material to find the optimal combination for your desired outcome.

- Use Raster Engraving Mode: For detailed engravings and image transfers, select the raster engraving mode on your laser engraving software.

-

Clean the Faux Leather:

Before engraving, ensure the surface of the faux leather is clean and free of dust or debris to avoid imperfections in the engraving on engraved on leather. Leather laser crafters know that preparation is key. If you're looking for where can you get leather engraved, consider using a Monport 100W CO2 Laser Machine.

- Hold Down the Material: Secure the faux leather flat onto the workbed using clamps or positioning tape to prevent movement during the engraving process.

- Maintain Proper Ventilation: Always operate the laser engraver in a well-ventilated area to remove fumes and smoke generated during the engraving process.

Additional Considerations for Faux Leather Engraving:

- Laser Beam Color: The Monport 100W CO2 Laser Machine utilizes a CO2 laser, which emits light in the infrared spectrum (invisible to the human eye). While the laser beam itself is not visible, the machine typically features a red light pointer that indicates the engraving path. This red light pointer helps you position your design and ensure the engraving occurs in the intended location.

-

Post-Engraving Care: Once the engraving is complete, gently remove any residual debris from the engraved area using a soft brush or compressed air. Avoid using harsh cleaning chemicals or abrasive materials on the faux leather as they might damage the surface. yag vs co2 laser.

What Makes Our Customers Successful When Laser Engraving and Laser Cutting Artificial Leather?

At Monport, we understand the importance of empowering our customers to achieve success with their laser engraving and cutting projects. Here are some key factors contributing to our customers' achievements with artificial leather: yag vs co2 laser.

- User-Friendly Machine Design: The Monport 100W CO2 Laser Machine boasts an intuitive control panel and user-friendly software, making it easy for beginners and experienced users alike to operate.

- Detailed Starting Point Settings: We provide comprehensive starting point settings for various materials, including faux leather, allowing customers to begin their projects with a solid foundation.

- Extensive Online Resources: Monport offers a wealth of online resources, including tutorials, FAQs, and troubleshooting guides, to assist customers in mastering their laser engraving and cutting skills.

- High-Quality Machine Construction: Our laser machines are built with durable and reliable components, ensuring consistent performance and optimal results for faux leather engraving and cutting.

Advantages of Monport 100w CO2 Laser for Engraved Leather

The Monport 100W CO2 Laser Machine offers several advantages specifically for engraving faux leather:

- Precise and Clean Engravings: The high-efficiency laser beam delivers precise and clean engravings, ideal for creating intricate designs and details on faux leather.

- Large Work Area: The spacious 20" x 28" workbed accommodates most faux leather sheets, allowing you to tackle projects of various sizes.

- Air Assist Function: The built-in air assist function helps remove smoke and debris during engraving, minimizing burning or melting of the faux leather.

- Faster Engraving Speeds: The machine's powerful laser beam allows for faster engraving speeds compared to some competitor models, increasing your project's efficiency.

- Wide Range of Material Compatibility: Beyond faux engraved leather, the Monport 100W CO2 Laser Machine can engrave and cut a variety of other materials, including wood, acrylic, glass, and fabric, offering exceptional versatility for your crafting endeavors.

Exploring the Creative Potential of Faux Engraved Leather

The Monport 100W CO2 Laser Machine unlocks a vast array of creative possibilities for engraving faux leather. Here are some inspiring ideas to get you started: yag vs co2 laser.

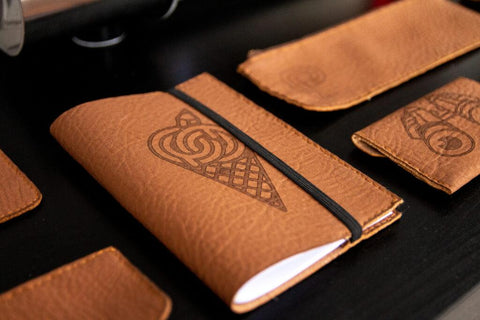

- Personalized Wallets and Phone Cases: Engrave names, initials, or custom designs on wallets, phone cases, and other leatherette accessories to create unique and personalized gifts.

- Crafting Decorative Coasters: Add a touch of elegance to your home decor by engraving faux leather coasters with intricate patterns, logos, or inspirational quotes.

- Engraved Keychains: Design and engrave faux leather keychains with personalized messages, team logos, or pet portraits for a practical and stylish accessory.

- Bookbinding and Journal Covers: Elevate your notebooks and journals by creating custom engraved faux leather covers, adding a touch of sophistication and personalization.

- Fashion Accessories: For a touch of DIY flair, engrave faux leather hat bands, belts, or handbag straps with unique designs or personal messages.

FAQs

The Monport 100W CO2 Laser Machine: Your Gateway to Flawless Faux Leather Engraving

In conclusion, the Monport 100W CO2 Laser Machine price cutters stands out as the perfect companion for your faux leather engraving endeavors. With its comprehensive features, user-friendly approach, and commitment to customer success, Monport empowers you to transform faux leather into stunning and personalized creations with engraved on leather. If you're wondering where can you get leather engraved, consider using a Monport 100W CO2 Laser Machine. black laser marking spray yag vs co2 laser.

Read More: Laser Engraving Faux Leather with the Monport 40W Pro CO2 Laser Engraver

Ready to embark on your faux leather engraving journey?

Visit the Monport website today to explore the Monport 100W CO2 Laser Machine and discover how it can elevate your crafting projects to the next level.

Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!