Laser engraving leather patches is a captivating blend of traditional craftsmanship and modern leather laser engraving technology. Whether you're a seasoned artisan or an enthusiastic beginner, this step-by-step guide will walk you through the process of creating stunning leather engraving designs using a laser engraving machine.

For those wondering where can you get leather engraved, the answer depends on your location and your needs—whether you're searching for DIY methods or professional services. Local experts and shops often provide laser engraving leather patches services, or you can invest in your own leather patch laser engraver for unmatched customization and control.

Read More : Laser Engrave on Leather: Create Stunning Patches with Monport Laser

Step 1: Selecting High-Quality Leather

The foundation of any leather engraving project lies in choosing premium-quality leather. Opt for leather that is smooth, supple, and consistent in thickness. Different types of leather offer unique characteristics, so consider texture, color, and finish. If you're still wondering where can you get leather engraved, many local providers also offer a variety of high-grade leather suitable for engraving with a leather patch laser engraver.

Step 2: Designing Your Patch

Use graphic design software like LightBurn to design your patch. Convert your artwork into vector format to ensure precision. Local shops that offer leather engraving near me can also help with design refinement if you're not familiar with design tools or are exploring where can you get leather engraved professionally with a leather patch laser engraver.

Step 3: Preparing the Leather

Secure the leather on the engraving bed using tape or clamps. A clean, stable surface prevents errors during the engraving process. Some workshops offering services for those asking where can you get leather engraved will also let you test samples before committing to your final design. This preparation stage is crucial for optimal performance of your leather patch laser engraver.

Step 4: Setting Up the Laser Engraving Machine

Adjust the machine settings to match your leather type and design. If you’re experimenting with a home machine and still wondering where can you get leather engraved for better quality, compare your results with those from local experts for benchmarking. A leather patch laser engraver allows you to fine-tune these settings for professional results.

Step 5: Engraving the Design

With the laser engraving machine calibrated, it's time to bring your design to life. Start the engraving process, keeping a close eye on the progress to ensure that the laser follows the designated paths accurately. Depending on the complexity of your design, the engraving process may take several minutes to complete, especially when using a leather patch laser engraver for intricate details.

Step 6: Finishing Touches

Once the leather engraving is finished, carefully remove the leather from the engraving bed. Use a soft brush or cloth to remove any residual ash or debris from the engraved areas. If desired, apply leather finish or conditioner to enhance the appearance and durability of the leather after using a leather patch laser engraver for your leather patches.

Step 7: Cutting the Patch

After engraving, use a sharp knife or cutting tool to trim the leather into the desired shape and size for your patch. You can opt for traditional shapes such as rectangles or circles, or get creative with custom shapes that complement your design. A leather patch laser engraver ensures precision in detailing, making your patches stand out with sharp and intricate engravings.

Step 8: Adding Details (Optional)

To further customize your leather patch, consider adding additional details such as stitching, edge painting, or hardware embellishments. These finishing touches can elevate the overall aesthetic and add a unique touch to your creation. Using a leather patch laser engraver ensures that your design is crisp and precise, providing a high-quality foundation for further customization.

Step 9: Enjoying Your Masterpiece

Once your leather patch laser engraver has completed the leather engraving, admire your handiwork and incorporate it into your desired project. Whether it's a personalized accessory, a branded merchandise item, or a decorative embellishment, your leather laser engraving patch is sure to impress with its craftsmanship and attention to detail.

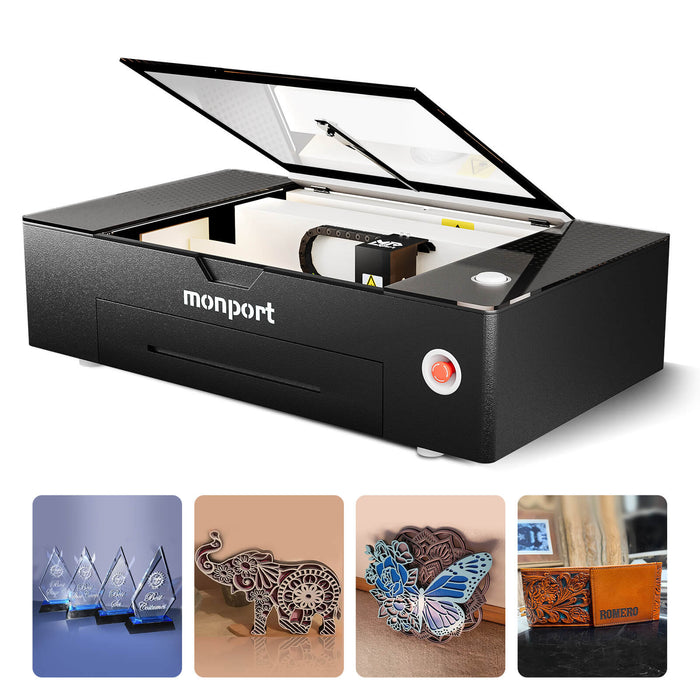

Introducing the Moport Onyx 55W CO2 Laser Engraver: Revolutionizing Leather Engraving

The Monport Onyx 55W CO2 Laser Engraver is a game-changer for leather engraving. Ideal for both professionals and beginners asking where can you get leather engraved with precision, this machine offers robust performance, a spacious work area, and advanced features like a 5MP camera and LightBurn compatibility.

Dimensions & Specifications

- Laser Power: 55W

- Machine Dimensions: 38.2" * 22.2" * 9.2" (970mm * 565mm * 234.5mm)

- Work Table Area: 20.08" (510mm) * 11.8" (300mm)

- Processing Area: 20.08" (510mm) * 11.8" (300mm)

- Max. Workpiece Height (without honeycomb tray): 2'' (51mm)

- Max. Engraving Speed: 600mm/s

- Max. Cutting Depth: 0.59'' (15mm) Basswood

- Precision: 0.001” (0.025mm)

- Control Software: RDWorks (provided); LightBurn (supported)

- Operating Systems: Windows/macOS

- Connection/Transmission: USB, Ethernet

- Weight: 45.6kg

ONYX CO2 Laser Features

1. Powerful and Efficient Performance: With its 55W laser tube, the Onyx 55W can effortlessly cut through 18mm plywood and 17mm acrylic in a single pass. Equipped with industrial-grade transmission solutions and customized motors, it achieves a carving accuracy of 0.001” while boasting a remarkable speed of 600mm/s, surpassing most diode engraving machines.

2. Practical 5MP Camera: The built-in wide-angle camera offers a preview function, enabling precise positioning and alignment of designs. Paired with the robust Lightburn software, this feature simplifies complex tasks, ensuring flawless results every time.

3. Versatile Engraving: The spacious 20"×12" workspace accommodates a wide range of creative endeavors. Additionally, the included upgraded rotary axis facilitates engraving on various cylindrical objects, expanding the scope of your projects. Furthermore, the pass-through function enables the engraving of longer items, providing limitless possibilities.

4. Multi-Material Engraving and Cutting: The Onyx 55W exhibits exceptional absorption efficiency across various materials, making it ideal for cutting acrylic, wood, leather, MDF, rubber, fabric, and more. Whether you're engraving on glass, ceramic, slate, coated metal, or anodized aluminum, this versatile machine delivers impeccable results every time.

5. Safer and Cleaner: Safety is paramount with the Onyx 55W. Its enclosed design features cover opening protection, an emergency stop button, and an indicator light alert system, ensuring comprehensive protection during operation. Moreover, the superior smoke evacuation system, equipped with a powerful exhaust fan, efficiently removes smoke, guaranteeing a cleaner working environment.

The Monport Onyx 55W CO2 Laser Engraver stands as a testament to innovation, precision, and reliability. From its powerful performance to its user-friendly features, it sets a new standard for leather patch engraving machine. With the Onyx 55W, artisans can unleash their creativity with confidence, knowing they have a trusted companion that delivers exceptional results with every engraving. Experience the difference today and elevate your craft to new heights with the Monport Onyx 55W CO2 Laser Engraver.

FAQs – blank leather patches for laser engraving

Q: Are blank leather patches for laser engraving suitable for beginners?

A: Yes, they are easy to use and ideal for learning laser engraving leather patches.

Q: What is the best laser engraver for leather patches?

A: A dedicated laser engraver for leather patches offers stable power and consistent output.

Q: Can I make laser engraved patches at home?

A: Yes, with proper ventilation and safety practices.

Q: Do laser leather patches fade over time?

A: No, well-made laser engraved leather patches remain visible for years.

Q: Is a leather patch engraver different from a normal laser?

A: A leather patch engraver is optimized for softer materials and detailed work.

Elevate Your Engraving with Monport Black Laser Marking Spray

Monport black laser marking spray is an essential tool for those looking to create permanent, high-contrast markings on a variety of metals, including aluminum, stainless steel, and brass. Ideal for use with CO2 laser engraving machines of 25 watts and above, this black laser marking spray ensures deep, durable marks that withstand the test of time. With its advanced nozzle technology, the spray is applied evenly, allowing for a smooth, professional finish every time. The quick-dry formula of this black laser marking spray helps streamline your workflow by drying in just five minutes, enabling faster production. After engraving, simply rinse the surface to reveal the sharp, dark markings created by the black laser marking spray, making it perfect for a wide range of applications from custom jewelry to industrial tool marking.

Conclusion

Laser engraving leather patches is a rewarding endeavor that combines artistic expression with technological precision. By following these steps and experimenting with different designs and techniques, you can create unique and visually striking leather patches that showcase your creativity and craftsmanship. So, fire up your leather patch engraving machine and let your imagination run wild as you embark on your leatherworking journey. If you're looking for leather engraving near me, this guide will help you achieve professional results with ease.

For further guidance on leather engraving and to explore a diverse range of premium laser machines, we invite you to visit the Monport website. Our platform offers comprehensive machine guides, providing valuable insights into the world of leather laser engraving technology. Whether you're a seasoned professional or a novice enthusiast, our resources can help you make informed decisions and unleash your creative potential. Additionally, browse through our extensive collection of premium laser machines, including the Onyx 55W CO2 Laser Engraver and many more, crafted to meet the diverse needs of artisans and businesses alike. Visit us today and embark on your journey towards precision, innovation, and excellence in laser engraving.

Celebrate Business Week with Monport! Enjoy up to 30% OFF on our premium laser engraving machines and unlock incredible free gifts to elevate your projects. Buy a CO₂ laser and receive a FREE Water Chiller, Rotary Axis, and LightBurn software. Purchase a Fiber Laser and get a FREE Rotary Axis. Plus, score a special $130 OFF on bundle deals and 30% OFF laser engraving materials. Don’t wait — use code BESTMP10 at checkout and click here to shop now!

Shop today and take advantage of Business Week specials – use code BESTMP10 at checkout for exclusive savings!

Click here to explore Monport laser engraving machines now!