Power and Wattage

The wattage of a diode laser directly impacts its cutting capability. A 40W diode laser offers a balance between power and precision, making it suitable for various wood cutting applications. However, it's essential to assess your specific needs. While higher wattage laser cut machines can cut through thicker materials more quickly, they may also generate more heat, potentially leading to charring or warping in delicate woodwork. Black laser marking spray can be a helpful addition to reduce heat damage and improve the contrast of engravings. Evaluate the thickness and type of wood you'll primarily be working with to determine if a 40W laser is sufficient for your projects.

Beam Quality and Precision

The quality of the laser beam emitted by a diode laser significantly influences the precision of cuts. Look for laser cut machines with high beam quality, characterized by a small spot size and minimal divergence. A focused, precise beam ensures clean, accurate cuts, especially when dealing with intricate designs or fine details in woodwork. Additionally, consider the laser's stability and consistency over long periods to maintain precise cutting performance throughout your projects. When using black laser marking spray, it’s important that the laser beam maintains consistent quality to achieve the best results.

Wavelength Compatibility

Different materials respond differently to varying wavelengths of laser light. For wood cutting, a diode laser operating at a wavelength around 1064 nanometers is typically preferred. This wavelength effectively penetrates wood while minimizing the risk of reflection or absorption issues that can occur with other wavelengths. Ensure that the laser's wavelength is suitable for wood cutting applications to achieve optimal results without compromising on efficiency or safety.

Cooling and Thermal Management

Effective thermal management is crucial for maintaining the longevity and performance of a diode laser. Continuous operation at high power levels can generate significant heat, potentially leading to premature component failure or degradation in cutting quality. Look for laser cut machines equipped with robust cooling systems, such as active cooling methods like water or air cooling. These systems help dissipate excess heat and ensure consistent performance even during prolonged use, safeguarding your investment and minimizing downtime.

Control and Integration

Seamless integration with your wood cutting machine's control system is essential for efficient operation and workflow management. Choose a diode laser that offers compatibility with common control interfaces and software protocols used in your crafting setup. Additionally, look for features such as adjustable power settings, pulse modulation, and real-time monitoring capabilities to fine-tune cutting parameters and optimize results based on the specific requirements of each project in your machine for crafts.

Safety Features and Compliance

Safety should always be a top priority when working with laser equipment. Select a diode laser that adheres to industry safety standards and regulations, such as FDA regulations in the United States or CE certification in Europe. Built-in safety features like interlocks, emergency stop buttons, and laser beam shielding help mitigate risks associated with laser cutting and protect both users and surrounding environments from potential hazards in a machine for crafts.

Monport 40W CO2 laser engraver: The Ultimate Choice for Wood Cutting Machine Crafts

Among the myriad options available, Monport 40W stands out as the premier choice for wood cutting enthusiasts and professionals alike. In this article, we explore why Monport 40W is the ultimate solution for laser cut machines crafts.

-

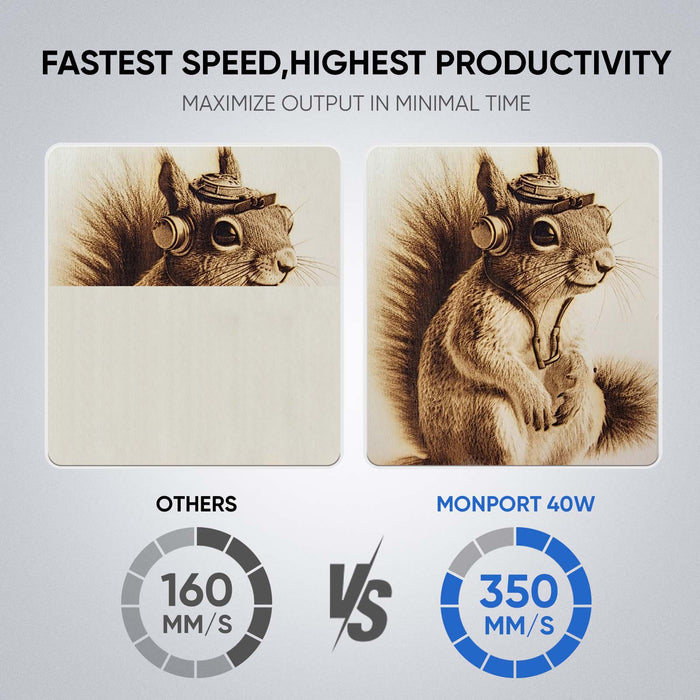

Cutting Power and Precision: At the heart of Monport 40W lies its exceptional cutting power and precision. With a 40W output, this diode laser strikes a perfect balance between power and control, allowing for precise cuts without compromising on speed. Whether you're working on intricate designs or cutting through thicker wood materials, Monport 40W delivers consistent, clean cuts with remarkable accuracy, ensuring impeccable results every time.

-

Superior Beam Quality: Monport 40W boasts superior beam quality, characterized by a small spot size and minimal divergence. This ensures that the laser beam remains focused and precise, even when cutting intricate patterns or fine details in woodwork. The high-quality beam of Monport 40W guarantees sharp edges and smooth finishes, enhancing the overall aesthetics of your projects and enabling you to bring your creative visions to life with unparalleled clarity.

-

Wavelength Optimization: With a wavelength optimized for wood cutting applications, Monport 40W penetrates wood with ease while minimizing the risk of reflection or absorption issues. Operating at a wavelength around 1064 nanometers, this diode laser ensures efficient material removal and minimal heat-affected zones, resulting in clean, burr-free cuts and preserving the integrity of the wood. Whether you're cutting hardwoods, softwoods, or engineered wood products, Monport 40W delivers exceptional performance across a wide range of wood materials.

-

Advanced Cooling System: Monport 40W is equipped with an advanced cooling system that effectively dissipates heat and ensures optimal thermal management during operation. Whether you're running a short cutting session or engaging in prolonged fabrication tasks, the cooling system of Monport 40W maintains stable laser performance and prevents overheating, safeguarding the longevity and reliability of the equipment. With Monport 40W, you can work with confidence, knowing that your laser is equipped to handle demanding cutting requirements with ease.

-

Seamless Integration and Control: Monport 40W offers seamless integration with wood cutting machine control systems, allowing for effortless operation and workflow management. Compatible with common control interfaces and software protocols, this diode laser enables precise control over cutting parameters, including power settings, pulse modulation, and cutting speed. With Monport 40W, you have the flexibility to adjust settings on the fly and fine-tune your cutting process to achieve optimal results for each project.

-

Safety and Reliability: Safety is paramount when working with laser equipment, and Monport 40W prioritizes user safety with built-in features and rigorous quality standards. From interlocks and emergency stop buttons to laser beam shielding and compliance with industry regulations, Monport 40W ensures a safe working environment for users and bystanders alike. Additionally, Monport 40W is engineered for reliability, with durable construction and components that withstand the rigors of continuous operation, minimizing downtime and maximizing productivity.

Conclusion

Choosing the best 40W diode laser for laser cut machines crafts requires careful consideration of various factors, including power and wattage, beam quality, wavelength compatibility, cooling and thermal management, control and integration, and safety features. By evaluating these factors against your specific needs and project requirements, you can ensure the selection of a diode laser that delivers precise, reliable performance and enhances the quality and intricacy of your woodwork creations in your machine for crafts.

Monport 40W stands as the ultimate choice for laser cut machines crafts, offering unparalleled cutting power, precision, and reliability. With superior beam quality, optimized wavelength, advanced cooling system, seamless integration, and robust safety features, Monport 40W empowers craftsmen and professionals to unleash their creativity and achieve flawless results in their woodwork projects. Whether you're a hobbyist, artisan, or industrial manufacturer, Monport 40W sets the standard for excellence in laser cut machines.

Experience the epitome of precision and innovation at the Monport website, your gateway to cutting-edge laser solutions.Visit our website today and unlock a world of endless possibilities!

Don’t Miss Out!

Take your wood cutting and laser cut machines crafts to the next level with the Monport 40W! Use code BESTMP10 at checkout – click here to shop now!