Leather is a highly versatile material used in various industries, including fashion, automotive, and furniture. One of the most innovative ways to enhance its appearance is through laser engraving. Laser engraving provides an accurate and efficient way of creating intricate designs on leather products. In Monport, a renowned supplier of laser engraving machines, the Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro, is the ideal machine for laser engraving on leather. In this article, we'll cover everything you need to know about laser engraving leather in Monport, including what leather goods can be engraved, factors to consider when choosing the right laser engraving machine, and tips for achieving quality results.

What Leather Goods Can be Laser Engraved?

Almost all leather products can be laser engraved. From wallets and belts to shoes and jackets, laser engraving can add a touch of individuality and style to any leather item. However, it is essential to consider the type of leather and its thickness when laser engraving.

Aspects to Remember in Leather Laser Engraving

Laser engraving on leather requires precision and accuracy. There are some key aspects to keep in mind to ensure that you achieve the best results:

- Thickness of Leather

Leather thickness plays a vital role in determining the optimal settings for engraving. Generally, thin leather requires less power for engraving, while thicker leather necessitates a higher power output.

- Cutting vs. Engraving

When engraving leather, it's essential to differentiate between cutting and engraving. Cutting involves making a clean and precise cut on leather, while engraving creates a design by burning the top layer of the leather. Different materials have specific metrics for cutting and engraving settings.

- Type of Leather

Different leather types have different properties that require unique settings. For example, synthetic leather requires less power for engraving as it's more sensitive to heat, while genuine leather requires more power because it's tougher.

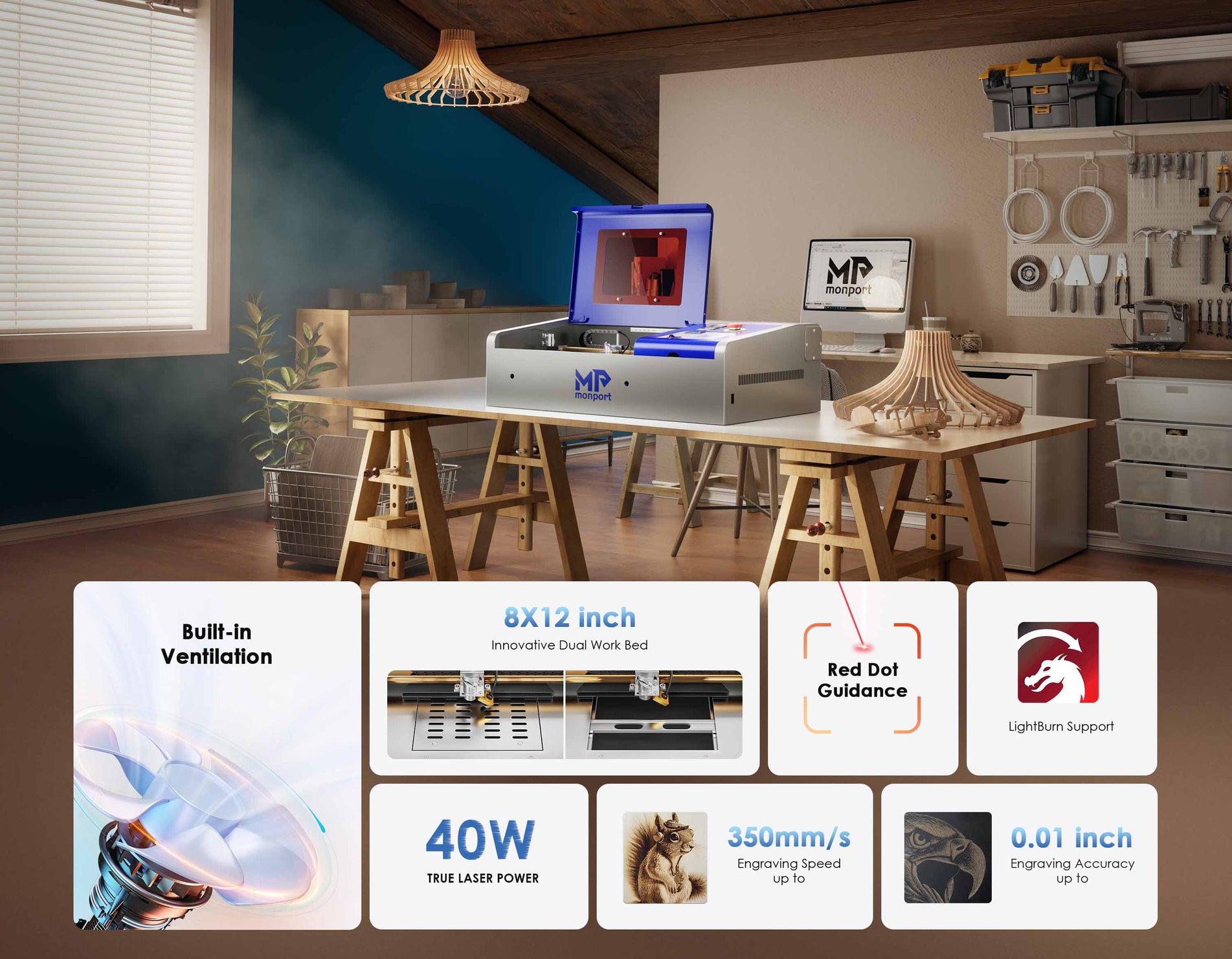

Choosing Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro is the Right Laser Engraving Machine for Leather

When it comes to laser engraving on leather, the Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro is the right machine for the job. It is designed specifically for beginners and professionals, with a wide range of features that make it easy to work with.

Features of Monport 40W Pro

- Air assist for precise cutting and engraving

- Lightburn software for easy design customization and control

- 12" x 8" working area for a variety of leather items

- 40W power output for efficient and accurate engraving

- Oxygen-free design for a cleaner and safer environment

Understanding Different Types of Leather for Laser Engraving

Leather is an organic material obtained from animal hides and skins. It is further categorized into different types, each with varying properties and thicknesses. Understanding different leather types is crucial in achieving quality results when laser engraving.

Types of Leather for Laser Engraving

- Full-grain leather

- Top-grain leather

- Suede leather

- Nubuck leather

- Patent leather

- Synthetic leather

Ready to elevate your leather projects? Explore the capabilities of the Monport 40W Pro and see how easy it is to create intricate, personalized designs on wallets, belts, jackets, and more. Take advantage of its user-friendly features and precision to achieve stunning results every time.

Tips for Achieving Quality Results with Leather Laser Engraving

Achieving quality results when laser engraving on leather requires proper preparation and technique. Here are some tips to help you get started:

- Design Preparation

Before engraving, it's essential to prepare your design for the best results. Ensure that you have the correct design file format and that the image resolution is high enough to produce clean and precise details.

- Leather Preparation

Properly preparing the leather surface is crucial in achieving quality results. Ensure that the leather is clean and free from oils and dirt. If necessary, sand the leather surface to achieve a smooth and uniform texture.

- Engraving Process

Once you have prepared your leather surface and design, it's time to start engraving. Use the recommended settings for your specific leather type to achieve the best results. Ensure that your focus lens is calibrated to produce sharp and precise lines.

Considerations for Selecting the Best Laser Engraving Machine for Leather

When selecting a laser engraving machine for leather, there are several factors to consider:

- Power Output

Ensure that the laser engraving machine has enough power to work on thick leather materials.

- Working Area

Consider the working area of the machine to ensure that it can accommodate your leather product.

- Software Compatibility

Choose a laser engraving machine that is compatible with the software you are using to design and control the engraving process.

- Price

Consider the cost of the laser engraving machine and ensure that it fits within your budget.

Conclusion

Laser engraving provides a unique and stylish way of enhancing leather products. With the right laser engraving machine, such as the Monport 40W Pro Lightburn-Supported (12" X 8") CO2 Laser Engraver & Cutter with Air Assist - 40W Pro, achieving quality results is easy. By understanding different leather types, preparing surfaces, selecting optimal settings, and utilizing proper techniques, laser engraving on leather products can be a fun and creative experience.

Click here and don’t miss your chance to bring your creative ideas to life with the Monport 40W Pro Lightburn-Supported CO2 Laser Engraver & Cutter. Start your journey into leather laser engraving today—unlock endless possibilities for personal and professional projects!