From personalized jewelry to custom keychains, laser engraving allows you to mark a variety of materials with stunning precision but can you laser engrave brass, a popular metal choice for its warm hue and versatility? Absolutely! This comprehensive guide delves into laser etching brass, exploring the process and recommending Monport GQ 30w Fiber Laser for efficient and precise brass laser cutting,top hobby laser cutter for metal.

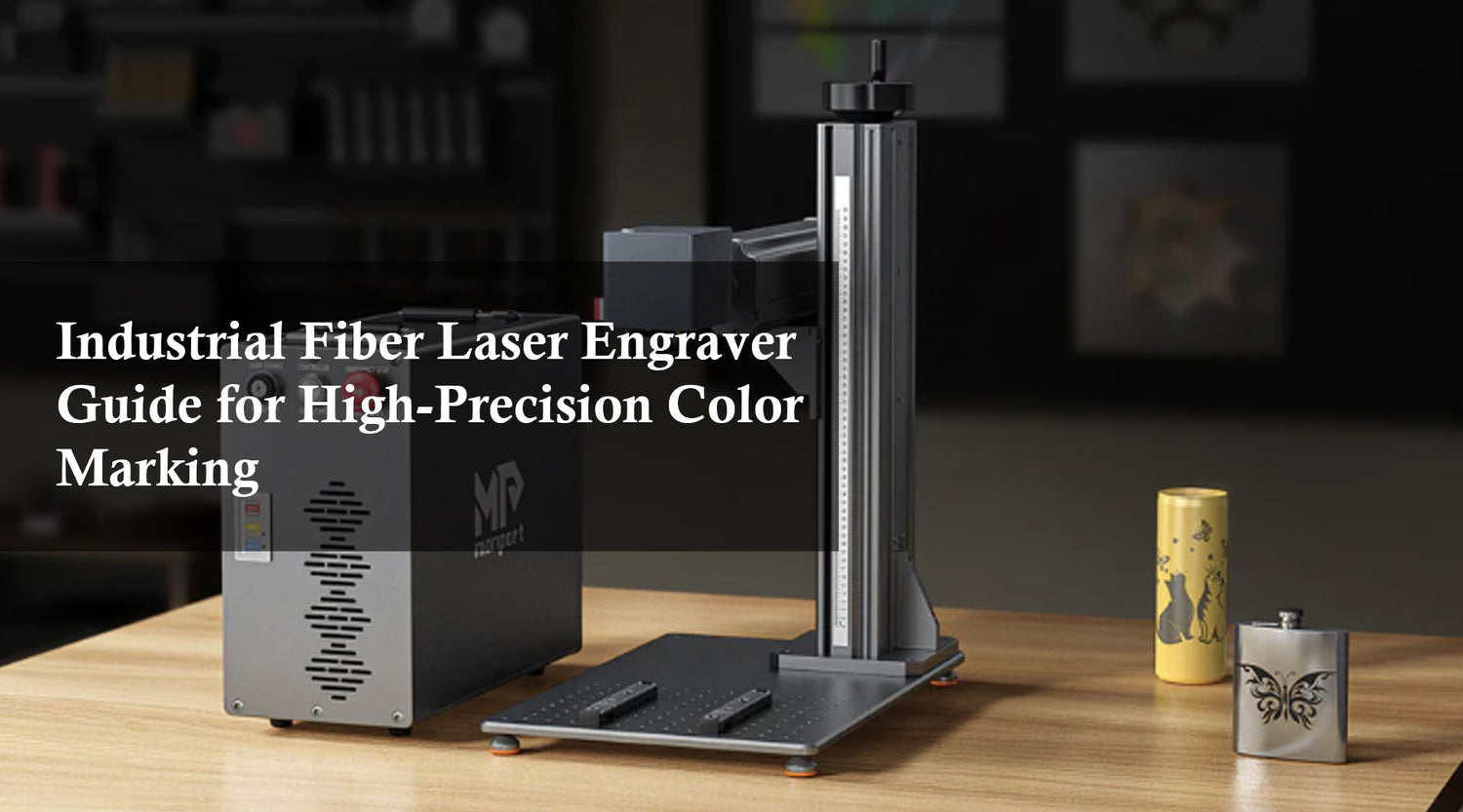

Monport GQ 30W (5.9" x 5.9") Fiber Laser Engraver & Marking Machine with FDA Approval

ReadMore : Mastering Brass Engraving with Monport GI60 Fiber Laser Engraver

Can You Laser Engrave Brass?

Yes, laser engraving brass is an excellent process for achieving precise and intricate designs. Its high reflectivity effectively absorbs the laser beam's energy, creating crisp and detailed engravings. Laser engraving brass offers numerous advantages:

- Durability: Engraved markings on brass are permanent and highly resistant to wear and tear, making them ideal for personalized items.

- Versatility: Brass comes in various finishes, offering a range of aesthetic options for your engraved projects.

- Aesthetics: Brass laser cutting creates a beautiful contrast on brass, highlighting the details of your designs.

Things to Consider When Laser Engraving Brass

While brass is well-suited for laser engrave brass applications, here are some crucial factors to keep in mind:

- Laser Type: CO2 lasers struggle to effectively engrave brass due to its reflective properties. Fiber lasers, on the other hand, excel at engraving metal due to their shorter wavelength and higher power density.

- Material Thickness: Hobby laser cut brass engraver typically have lower wattages, limiting their ability to cut through thick brass. For engraving on thicker brass sheets, consider higher-wattage industrial lasers.

- Surface Finish: Polished brass surfaces offer the best results for laser cut engraving, as they provide optimal laser beam absorption. Rough or weathered brass surfaces may require additional preparation or different settings for successful brass laser cutting.

Monport GQ 30W Fiber Laser: Top Hobby Laser Cutter for Metal

The Monport GQ 30W Fiber Laser is a powerful and user-friendly option for brass laser cutting. Here's what makes it stand out:

- Galvo-tech Control: Utilizes a Sino-Galvo scanning system for precise and high-speed laser beam delivery, ensuring crisp and detailed brass laser cutting.

- Raycus Fiber Laser Source: This reliable source excels at marking various metals, including brass, making it perfect for laser cut projects.

- Advanced Workspace: The built-in grid and removable positioning bars enable precise material placement for your brass laser cut projects.. Additionally, it supports an optional rotary axis (sold separately) for brass laser cutting on curved surfaces.

- Portable Size: This compact design allows for easy setup on a desk or portability to different workspaces.

- Laser Guidance: An external red dot locator assists with accurate laser focus setup for optimal engraving results on brass.

- Manual Focus: The manual focus wheel provides precise control for adjusting the laser focus on various materials like brass, silver, and gold.

Inspiring Project Ideas for Laser Engrave Brass:

With your hobby laser cutter ready, here are some exciting project ideas to get you started:

- Personalized Jewelry: Engrave initials, names, or meaningful symbols onto brass pendants, bracelets, or cufflinks for unique and treasured gifts.

- Custom Keychains: Design and engrave keychains with logos, inspirational quotes, or pet portraits to add a personal touch to everyday items.

- Pet ID Tags: Design stylish and durable pet ID tags with laser-engraved information and decorative elements to ensure the safe return of your furry companions.

- Bottle Openers: Engrave logos, names, or playful messages onto brass bottle openers for a unique and functional housewarming gift.

- Musical Instrument Picks: Personalize guitar picks or drum sticks with engraved names, initials, or band logos for a musician's treasured accessory.

Additional Tips for Laser Engrave Brass

- Experiment with Settings: Always perform test engravings on scrap brass pieces to fine-tune laser power, speed, and scanning settings for desired results.

- Proper Ventilation: Laser engraving brass can generate fumes. Ensure proper ventilation in your workspace to avoid inhaling harmful particles.

- Safety Precautions: Laser engraving involves working with high-powered lasers. Wear appropriate eye protection designed for the specific laser wavelength used by your brass engraver.

- Software and Design: Most laser cutters come bundled with compatible software for design creation and sending projects to the brass engraver. Ensure your vector artwork is optimized for laser engraving with closed paths and appropriate fill settings.

Laser Etching Brass: Frequently Asked Questions (FAQ)

In addition to the information above, here are some commonly asked questions regarding laser etching brass:

- What are the fumes produced during brass laser cutting, and how can I stay safe?

Laser etching brass generates fumes that may contain metal particles and other airborne contaminants. Here's how to prioritize safety:

- Ventilation: Always operate your laser cutter in a well-ventilated area with a fume extractor to remove harmful particles.

- Respirator: When necessary, consider using a respirator with appropriate filters for metal dust and fumes.

- Can I paint or color laser engraved brass?

Yes, you can paint or color laser engraved brass to add vibrancy and personalize your projects further. However, the success depends on the type of paint and the surface preparation. Here are some tips:

- Surface Cleaning: Thoroughly clean the engraved brass surface with rubbing alcohol to remove any oils or residues that might affect paint adhesion.

- Paint Choice: Select a paint specifically formulated for metal surfaces. Consider using acrylic or enamel paints for durability.

- Test on Scrap: Apply the paint to a scrap piece of brass first to ensure compatibility and desired color outcome.

- Multiple Coats: Depending on the paint and desired opacity, you may need to apply multiple thin coats, allowing each layer to dry completely before applying the next.

- Clear Coat (Optional): A final coat of clear sealant can help protect the paint and enhance its longevity.

- How to clean laser engraved brass?

For routine cleaning of your engraved brass pieces, follow these steps:

- Gentle Cloth: Use a soft, lint-free cloth to dust or wipe away any surface dirt.

- Soap and Water (Optional): For a more thorough cleaning, you can use mild soap and lukewarm water. Ensure the brass is completely dry after cleaning.

- Avoid Abrasives: Never use harsh chemicals, abrasive cleaners, or scouring pads, as these can damage the engraved surface.

- Can I laser engrave chrome brass?

Chrome plating adds a shiny, reflective layer to brass. While technically possible to engrave through the chrome to reveal the brass underneath, the process requires a more powerful laser and precise settings to avoid damaging the brass itself. It's generally recommended to use unplated brass for optimal laser etching brass results.

- Where can I find high-quality brass for laser engraving?

Many online and physical stores offer brass sheets and blanks specifically for crafting and laser etching brass projects. Look for reputable metal suppliers or craft stores that carry a variety of brass thicknesses and finishes.

By following these tips and exploring the inspiring project ideas, you can embark on your brass laser cutting journey with confidence and creativity. Remember to prioritize safety, experiment with settings on scrap materials, and unleash your artistic vision to create stunning and personalized brass pieces!

Unlock Flawless Metal Marking with Monport Black Laser Marking Spray

When it comes to creating professional-grade metal engravings, Monport black laser marking spray is a must-have for makers, hobbyists, and professionals alike. This powerful aerosol spray is specially formulated to work with CO2 laser brass engraver of 25 watts and above, producing permanent black markings with exceptional contrast. Whether you're working on stainless steel, brass, or aluminum, the black laser marking spray bonds effortlessly to the surface, allowing for detailed and precise designs. Its fine-particle formula and anti-clog nozzle ensure smooth, even coverage every time. Drying in just five minutes, the black laser marking spray is easy to use and leaves no sticky residue after rinsing. From customizing jewelry to labeling tools or decorating metalware, the black laser marking spray from Monport delivers clean, bold results that last.

Conclusion

Laser etching brass opens up a world of creative possibilities for hobbyists and makers. By choosing the right laser cutter, understanding the material properties, and following safety guidelines, you can achieve stunning results on your brass projects. The Monport GQ 30W Fiber Laser and other reputable hobby laser cutters for metal offer the power and precision needed to bring your creative visions to life. So, embrace the possibilities of laser engraving and start exploring the beauty of marking brass with stunning details!

Ready to elevate your metal engraving craft? Don’t wait—get your Monport GQ 30W Fiber Laser now! Enter BESTMP10 at checkout for an exclusive discount—click here to shop and start creating flawless brass engravings today!

Read More: How to Create Vivid Squid Game Pins with a MOPA Fiber Laser: A Guide for Creative Engraving