Plywood sheets have become a cornerstone for innovative projects and profitable enterprises. As we look ahead, exploring business idea 2025 reveals countless opportunities for entrepreneurs to leverage these versatile materials. From crafting furniture to intricate engravings, plywood offers durability, affordability, and creativity, making it an essential component for forward-thinking businesses. Integrating laser engraving into plywood projects can unlock new revenue streams, providing an edge in a competitive market. This guide highlights the benefits of desktop engravers, explores the cost of CO2 laser machines, and introduces the Monport 60W CO2 Laser Engraver & Cutter as the ideal tool for entrepreneurs looking to capitalize on plywood-based ventures.

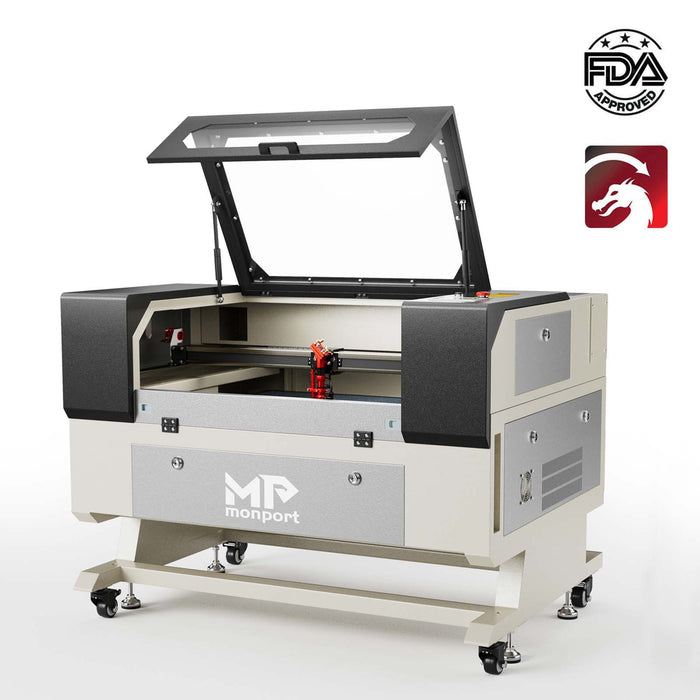

Monport 60W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus

The Benefits of Desktop Engravers for Plywood Sheets

Desktop engravers have revolutionized small-scale manufacturing and personalized product creation. For those exploring business idea 2025, investing in a desktop engraver is a game-changer. These compact machines provide precision, efficiency, and versatility, enabling users to craft intricate designs on plywood sheets and other materials.

Key Benefits:

- Cost-Effective Production: Desktop engravers offer high-quality results at a fraction of the cost of larger industrial machines.

- Space-Saving Design: Their compact size makes them suitable for home-based businesses or small workshops.

- Versatile Applications: Ideal for engraving wood, acrylic, leather, and more, desktop engravers expand creative possibilities.

- Ease of Use: Modern engravers feature intuitive controls and software compatibility, reducing the learning curve for beginners.

Exploring CO2 Laser Machine Cost for Plywood Sheets Projects

Understanding CO2 laser machine costs is crucial for anyone considering business idea 2025 involving plywood sheets. CO2 lasers are known for their precision, speed, and ability to cut and engrave a wide range of materials.

Factors Influencing Cost:

- Power and Speed: Higher wattage machines, like the Monport 60W, offer faster cutting and deeper engraving capabilities.

- Work Area Size: Larger engraving surfaces accommodate bigger plywood sheets, increasing project flexibility.

- Features and Accessories: Autofocus, air assist, and safety sensors enhance functionality but may impact pricing.

- Brand and Quality: Investing in reputable brands ensures durability, precision, and long-term value.

Average Cost Breakdown:

- Entry-Level Machines (40W-50W): $500 - $1,500

- Mid-Range Machines (60W-80W): $2,000 - $5,000

- High-End Industrial Machines (100W+): $6,000 and above

Plywood Sheets Business Idea 2025: Laser Engraving Wood Projects

Laser engraving on plywood sheets presents numerous profitable avenues for those pursuing business idea 2025. From personalized home decor to custom signage, the demand for engraved plywood products continues to grow.

Creative Project Ideas:

- Customized Furniture: Engrave intricate patterns or logos onto tabletops and cabinets.

- Decorative Wall Art: Craft unique, personalized wall hangings and signage.

- Jewelry and Accessories: Design lightweight, engraved plywood jewelry pieces.

- Event Decorations: Create customized decor for weddings, parties, and corporate events.

- Educational Tools: Produce engraved educational materials and puzzles for children.

Why Monport 60W CO2 Laser Engraver is the Best for Plywood Sheets Business Idea 2025

The Monport 60W CO2 Laser Engraver & Cutter stands out as the ultimate machine for entrepreneurs looking to capitalize on plywood sheets and launch their business idea 2025. Here’s why:

Dimension & Specifications:

- Machine Dimension: 49.2’’ x 36'' x 36.2''

- Working Dimension: 20"x 28"

- Pass-through Dimension: 27.5"x3.7"

- Maximum Engraving Speed: 800mm/s

- Maximum Cutting Speed: 400mm/s

- Max Engraving Depth: 10mm

- Min Engraving Depth: 0.01mm

- Z-depth: 8.6"

- Product Weight: 319.7 lbs

Standout Features:

- Fireproof Viewing Window: Protects against fire accidents, ensuring user safety during laser operations.

- Aeronautical Aluminum Rail: Enclosed to prevent smoke and debris from affecting precision.

- Laser Protective Glasses: Safeguards users from harmful laser radiation.

- Ruida Digital Controller: Compatible with LightBurn, AutoCAD, and CorelDRAW, allowing seamless project management.

- High Speed and Resolution: Engraving speeds up to 800mm/s with resolutions up to 4500 dpi.

- Autofocus: Eliminates manual adjustments, streamlining the engraving process.

- Built-in Air Assist: Clears debris and heat, ensuring clean and precise cuts.

- Red Dot Guidance: Provides visual laser head positioning for accurate project alignment.

Q&A About Monport Laser Engravers

Q: Why choose Monport over other laser engravers? A: Monport laser engravers are known for their precision, durability, and user-friendly designs. The Monport 60W CO2 Laser Engraver, in particular, offers exceptional speed, depth, and versatility for plywood sheets projects.

Q: Can the Monport 60W engrave on thick plywood sheets? A: Yes, it can engrave up to 10mm deep, making it suitable for a variety of business idea 2025 applications.

Q: Is the Monport 60W easy to operate for beginners? A: Absolutely. The machine features an intuitive control panel, autofocus, and compatibility with multiple software platforms.

Q: What safety features does the Monport 60W have? A: The engraver includes a fireproof viewing window, laser protective glasses, and automatic shutdown sensors.

Key Takeaways

- Plywood sheets offer limitless potential for entrepreneurs exploring business idea 2025.

- Desktop engravers enable cost-effective, high-precision project creation.

- The Monport 60W CO2 Laser Engraver excels in speed, accuracy, and safety, making it the perfect investment for plywood engraving businesses.

Conclusion

Launching a business idea 2025 centered around plywood sheets is a lucrative and creative venture. The Monport 60W CO2 Laser Engraver & Cutter empowers entrepreneurs to craft unique, high-quality products with ease. Visit monportlaser.com to explore their full range of laser engraving solutions and take the first step toward building a thriving plywood-based business.