Laser engraving opens up a world of possibilities on how to engrave on metal with a laser engraver and transform it into a meaningful, one-of-a-kind piece. Metal, with its strength and durability, has served humanity for centuries. But beyond its functional aspects, metal offers a unique canvas for personalization and artistic expression.

Whether you're a seasoned artisan or a curious beginner, this guide explores four popular methods for engraving metal, highlighting their advantages and guiding you toward the perfect technique for your needs. Plus, we'll delve into the exciting world of laser engraver for metal, a modern marvel that revolutionizes metal marking and metal engraving with precision and versatility, making it easier than ever to create designs beautifully carved into metal.

Monport Fiber Laser: Perfect Partner on How to Engrave on Metal

Beyond the specific features of the GI30 and GP20, Monport's fiber laser engravers for metal engraving offer several advantages:

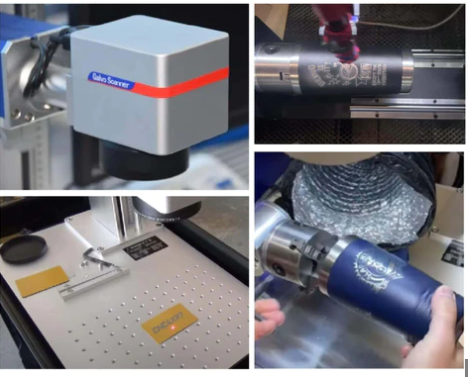

- Galvo-tech Control: Experience incredible speed and accuracy with the Sino-Galvo system.

- Raycus Fiber Laser Source: Enjoy a long lifespan and the ability to mark most metals.

- Upgraded Button Design: Prioritize safety and ease of use with the emergency button, key switch, and dual fans.

- Pre-assembled and Portable: Dive right into your projects with the hassle-free setup and compact design.

- Advanced Workspace: Ensure precise material placement with the built-in grid and optional rotary axis.

- Additional Laser Guidance: Achieve perfect focus with the external red dot locator and manual focus system.

1. Hand Engraving: Time-Tested Tradition on How to Engrave on Metal

For centuries, artisans have used hand engraving to inscribe metal with intricate details, producing timeless works carved into metal by hand. This traditional method is one of the oldest answers to how do you engrave metal without machines, using tools like gravers, chisels, and hammers to manually carve designs.

Advantages:

- Unmatched control and detail for intricate designs.

- Traditional aesthetic with a handcrafted feel.

- Relatively low initial investment (tools and consumables).

Disadvantages:

- Requires significant skill and practice to master.

- Time-consuming process for complex designs.

- Limited to surface-level engraving.

2. Rotary Engraving: Precision and Versatility on How to Engrave on Metal

Rotary engraving machines bring automation to the process and are another way to answer how do you engrave metal precisely and efficiently. These machines use spinning tips—often diamond or carbide—to carve designs carved into metal with accuracy and depth.

Advantages:

- Faster and more efficient than hand engraving.

- Suitable for intricate designs and lettering.

- Accommodates various metal types and thicknesses.

- User-friendly software simplifies design import and editing.

Disadvantages:

- Higher initial investment compared to hand engraving.

- Limited to 2D surface engraving.

- May require practice to achieve desired depths and finishes.

3. Chemical Etching: Artistic Exploration on How to Engrave on Metal

Chemical etching answers how do you engrave metal chemically, using acid or other corrosive substances to etch away unprotected areas. It’s often used in artistic applications and detailed pattern work that results in unique effects carved into metal.

Advantages:

- Ideal for intricate patterns and artistic designs.

- Capable of achieving deeper engravings than other methods.

- Offers unique textural and artistic effects.

Disadvantages:

- Requires careful handling of chemicals and proper safety precautions.

- Results can be less predictable than other methods.

- Limited to specific types of metal suitable for etching.

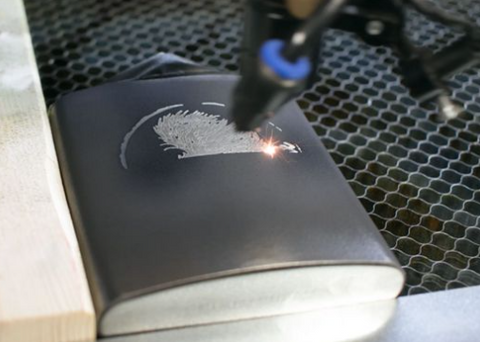

4. Laser Engraver for Metal: Modern Marvel for Metal Marking

In the search of How to Engrave on Metal, laser engraving technology stands as a game-changer. Laser engravers for metal utilize focused beams of light to vaporize material with unparalleled precision and detail, allowing intricate designs carved into metal at microscopic accuracy.

Advantages:

- Unmatched precision of laser engraver for metal and detail for intricate designs.

- Capable of deep engraving and 3D marking.

- Fast engraving speeds of laser engraver for metal for efficient production.

- User-friendly software simplifies design manipulation.

- Wide range of compatible metals and thicknesses.

Disadvantages:

- Highest initial investment compared to other methods.

- Requires some technical understanding for optimal use.

- May not be suitable for very small or delicate objects.

Monport Fiber Laser Engraver for Metal: Your Gateway to Metal Marking Magic

For those seriously exploring how do you engrave metal with professional results, Monport’s fiber laser engravers—like the GI30 and GP20—are top-tier solutions. These machines provide speed, accuracy, and user-friendly functionality perfect for both hobbyists and professionals.

Introducing the GI30 and GP20 Fiber Laser Marking Machines:

Monport Laser boasts a range of fiber laser engravers for metal, catering to diverse needs and budgets. Let's delve into two popular models:

1. GI30 Fiber Laser:

- Full-Color Marking: Imagine vibrant designs and high-contrast engravings on stainless steel and anodized aluminum.

- Unmatched Precision: Achieve cuts as precise as 0.05mm per pass with an accuracy of ±0.1 micron.

- Integrated Design: Enjoy a lighter, smaller, and user-friendly experience without compromising performance.

- Electric Lifting Focus: This beginner-friendly feature ensures effortless focusing and optimal results.

- LightBurn Compatibility: Design freely with the included EZCad 2.0 software and LightBurn compatibility.

- Industry-Leading Heat Dissipation: Maintain peak performance with built-in air cooling and unique side panel openings.

- Premium Craftsmanship: Experience the quality and durability of an anodized aluminum oxide casing.

2. GP20 Fiber Laser:

- Excellent Marking Capability: Mark at speeds of up to 10,000mm/s with exceptional precision and flexibility.

- MTTF exceeding 100,000 hours: Enjoy a reliable machine built for long-lasting performance.

- Shares all the benefits of the GI30 Fiber: Integrated design, electric lifting focus, LightBurn compatibility, and more!

Beyond the specific features of the GI30 and GP20, Monport's fiber laser engravers for metal engraving offer several advantages:

- Galvo-tech Control: Experience incredible speed and accuracy with the Sino-Galvo system.

- Raycus Fiber Laser Source: Enjoy a long lifespan and the ability to mark most metals.

- Upgraded Button Design: Prioritize safety and ease of use with the emergency button, key switch, and dual fans.

- Pre-assembled and Portable: Dive right into your projects with the hassle-free setup and compact design.

- Advanced Workspace: Ensure precise material placement with the built-in grid and optional rotary axis.

- Additional Laser Guidance: Achieve perfect focus with the external red dot locator and manual focus system.

FAQs

1. What does “carved into metal” mean in the context of engraving?

“Carved into metal” refers to creating designs, text, or patterns directly onto the surface of metal using various engraving methods. It can be done by hand, with rotary tools, chemical etching, or advanced laser engravers like the Monport Fiber Laser series.

2. What is the best method to get intricate designs carved into metal?

For the highest precision and versatility, laser engraving is considered the best method. Fiber laser engravers, such as the Monport GI30 and GP20, can achieve intricate details, full-color markings, and deep engravings with excellent accuracy.

3. How does a laser engraver differ from traditional hand engraving?

Traditional hand engraving involves manually using tools like chisels or gravers to create designs carved into metal, requiring significant skill and time. Laser engraving, on the other hand, uses focused light beams to vaporize the surface with unmatched speed, precision, and repeatability.

4. Can all metals be carved into metal designs using laser engraving?

Most metals—including stainless steel, aluminum, brass, and titanium—can be carved into metal designs using a fiber laser engraver. However, the power and settings may vary depending on the metal type and desired engraving depth.

5. Why choose Monport Fiber Laser Engravers for carving into metal?

Monport Fiber Laser Engravers offer speed, precision, and user-friendly features like electric lifting focus, LightBurn compatibility, and advanced heat dissipation. They are ideal for hobbyists and professionals who want detailed and lasting designs carved into metal efficiently.

Unlock the Potential of Your Metal Projects with Monport Fiber Laser Engraver for Metal

With Monport's fiber laser engravers for metal, the possibilities of metal engraving are endless. Mark logos, personalize gifts, create intricate designs on jewelry, or add functional labels to industrial parts – the choice is yours. Every creation can be beautifully carved into metal, making it a lasting work of art. Unleash your creativity and explore the magic of metal marking with Monport Laser!

Visit Monport's website today to discover the perfect fiber laser engraver for metal for your needs and embark on a journey of metal marking mastery!