Introduction

To ensure optimal performance and longevity of the machine, proper cleaning and maintenance are essential. In the laser engraving game, two big names always compete for excellence: black laser marking spray : Monport and OMTech Polar.

In this article, we will provide step-by-step instructions on how to effectively clean and maintain your OMTech Polar laser engraver machine as well as your Monport engraving machine.

Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus

Step by step guide on cleaning your laser cutting machine:

Turn off the Machine and Disconnect the Power Cord

Before beginning any cleaning or maintenance procedures, ensure that the engraving machine is switched off and unplugged from the power supply. This is to protect yourself and prevent any damage to the laser engraver machine.

Cleaning the Lens

The lens is one of the most critical components of the laser engraver, and keeping it clean is vital to maintain its performance. To clean the lens, take a microfiber cloth and gently wipe the lens in a circular motion. Avoid using any harsh chemicals or solvents, and never touch the lens with your fingers.

Cleaning the Exhaust Fan

The exhaust fan is responsible for removing smoke and fumes produced during the engraving process. To keep it clean, use a soft-bristle brush or a vacuum with a brush attachment to remove any debris or dust that has accumulated on the fan blades.

Cleaning and Replacing the Air Filter

The air filter helps to remove particles from the air before it is circulated through the laser engraver machine. Over time, the air filter can become clogged and reduce the machine's efficiency. To clean the air filter, remove it from the engraving machine, tap it lightly to remove any dust, and clean it with a soft brush. If the filter is damaged or excessively dirty, it may need to be replaced.

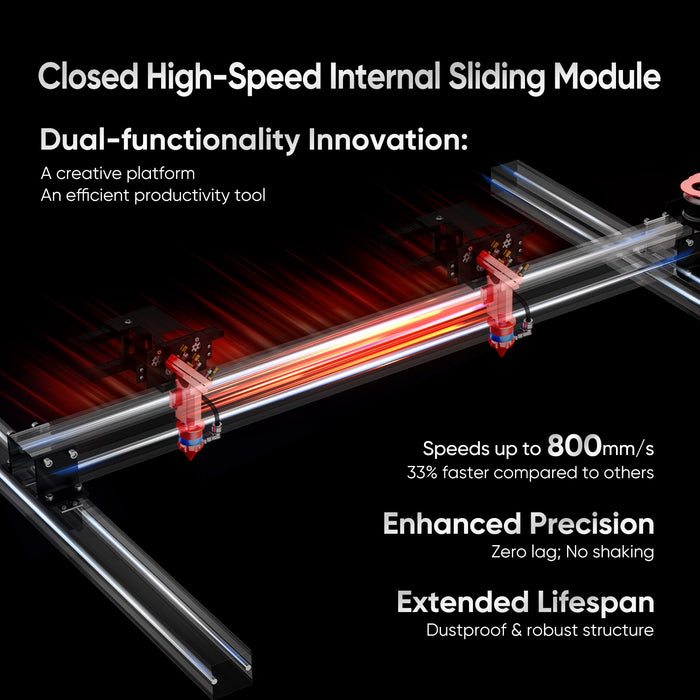

Maintaining the Rails

The rails on the laser engraver should be regularly maintained to ensure smooth movement of the laser head. Use a clean, dry cloth to wipe the rails clean and apply a light lubricant if necessary.

Checking and Tightening Screws and Bolts

After prolonged use, screws and bolts on the laser engraver may become loose. It's essential to check and tighten them regularly to prevent any unnecessary damage or safety hazards, especially when using black laser marking spray.

If you're looking for an affordable engraving machine that is easy to maintain and efficient, the Monport 80W laser engraver machine is for you!

Monport 80W Laser Cutting Machine: The Best Engraver for Precision and Efficiency

When it comes to laser engraving, precision, efficiency, and reliability are paramount. Monport, a leading provider of laser cutting machines, offers the 80W CO2 Laser Engraver & Cutter, a powerhouse machine that stands out among its competitors. Let's explore the key features and advantages that make the Monport 80W Laser Cutting Machine the best choice for engraving projects.

-

Unmatched Precision and Detail

The Monport 80W Laser Cutting Machine is equipped with advanced laser technology that ensures superior precision and detail in every engraving. With its exceptional cutting and engraving capabilities, it can create intricate designs on a wide range of materials, including wood, acrylic, leather, and more. The autofocus feature further enhances precision by automatically adjusting the focal length, resulting in consistently sharp and accurate engraving.

-

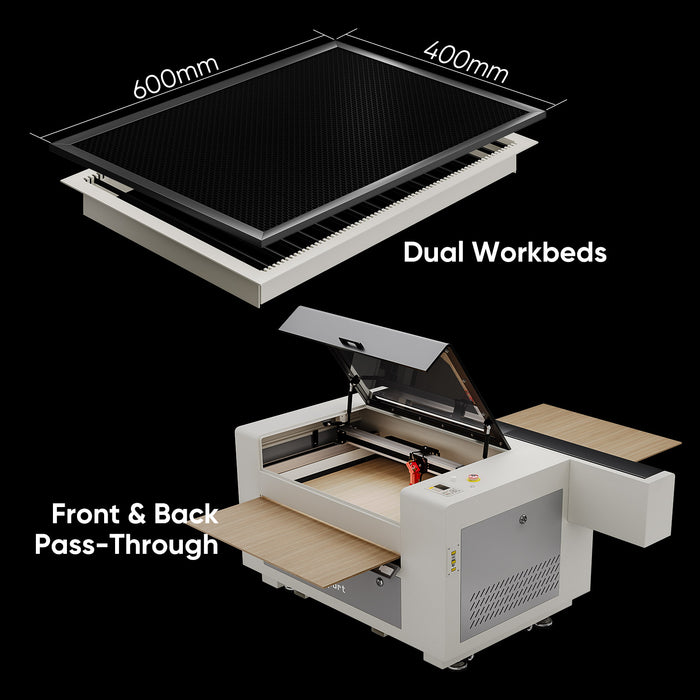

Powerful Performance

With a power output of 80W, the Monport laser cutting machine delivers impressive performance, allowing for faster and more efficient engraving. Whether you are working on small or large-scale projects, the machine's high-powered laser ensures excellent results with enhanced speed and productivity. The 24" x 16" working area provides ample space for a variety of engraving tasks, accommodating various sizes and shapes of materials.

-

User-Friendly Design and Software

Monport understands the importance of user-friendliness, and their 80W Laser Cutting Machine reflects this. The intuitive interface and easy-to-use controls make it accessible to both beginners and experienced engravers. Additionally, the machine is compatible with various design software, allowing users to unleash their creativity and work with their preferred design programs seamlessly.

-

Safety Measures and Durability

Safety is a top priority when working with laser engravers, and Monport ensures that their 80W Laser Cutting Machine adheres to the highest safety standards. The machine is equipped with protective features, including an emergency stop button and an enclosure to contain the laser beam. This provides peace of mind while operating the machine, especially in professional settings.

Furthermore, the Monport 80W Laser Cutting Machine is built to last. Constructed with durable materials and designed for heavy-duty usage, it offers a long lifespan and minimal maintenance requirements. This ensures a reliable and consistent performance throughout its usage.

-

Exceptional Customer Support

Monport takes pride in providing exceptional customer support to their clients. By choosing the 80W Laser Cutting Machine, customers gain access to a knowledgeable support team that is ready to assist with any inquiries or technical issues they may encounter. This level of support adds value to the overall ownership experience, giving users confidence and peace of mind.

The Monport 80W Laser Cutting Machine is undoubtedly a top-tier engraver that combines precision, efficiency, and reliability. With its exceptional cutting capabilities, user-friendly design, rigorous safety measures, and excellent customer support, it stands out as the best choice for a wide range of engraving applications. Whether you are a hobbyist, a small business owner, or a professional engraver, the Monport 80W Laser Cutting Machine will undoubtedly elevate your projects to new heights of quality and efficiency.

Click here to learn more about the Monport 80W Laser Cutting Machine.

Conclusion

Cleaning and maintaining your OMTech Polar and Monport laser engraver machine is essential to ensure its longevity and optimal performance. Regularly cleaning the lens, exhaust fan, air filter, and rails, and tightening screws and bolts will not only extend the life of your engraving machine but also ensure safety during operation, especially when using black laser marking spray.

Follow the step-by-step instructions in this article to keep your laser cutting machine in top condition and ready for any engraving project. Make sure to visit the monport website and discover the premium, affordable machines we offer!