50W Fiber Laser

Fiber Laser Marking vs Fiber Laser Cutting Machine

In this blog post, we explore the advantages of fiber laser marking over cutting, highlighting its efficiency, accuracy, and versatility. Fiber lasers use a high-powered beam to etch materials at a molecular level, allowing for intricate designs without stencils. Monport offers a range of fiber laser marking machines, ideal for businesses seeking quality results on various materials. Whether for personal projects or industrial applications, Monport's machines provide user-friendly operation and cost-effective solutions. Discover how fiber laser technology can elevate your marking processes.

Read more50W Fiber Laser

Best Laser Engravers for Tumblers, Cups & Mugs

Learn how a tumbler laser engraver and cup engraver can personalize stainless steel, ceramic, and glass drinkware. Explore Monport fiber and CO₂ laser options, rotary axes, and black marking spray for flawless, professional designs.

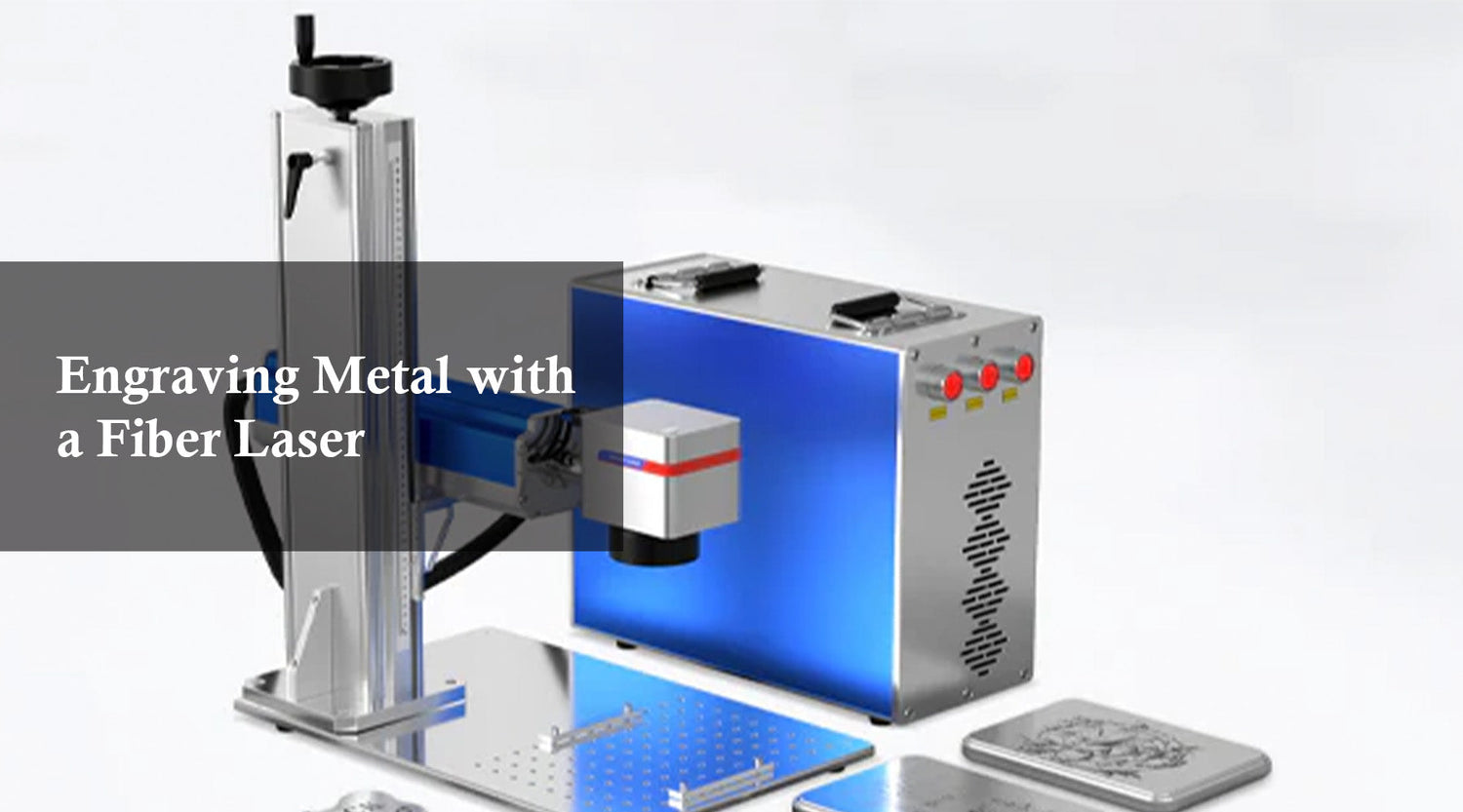

Engraving Metal with a Fiber Laser

Metal laser engraving is a great application for a fiber laser. High power, excellent beam quality, and long lifetimes are all features of fiber lasers. They are a great option for many applications because they are also affordable and simple to maintain. The fiber laser engraver is the perfect tool for creating high-quality, long-lasting marks on a range of objects. It uses a focused beam output which is quickly and precisely directed by two mirror-mounted, high-speed precision motors. Fiber laser engraving has many applications, from integrated circuit chips and computer parts to aerospace equipment, jewelry, home appliances, and tobacco. And it's not just for big businesses - small businesses, hobbyists, and amateurs alike are utilizing fiber laser engraving machines to create beautiful metal artworks, commercial plaques, and decorative tiles. With laser engraving, projects can be completed quickly and efficiently, giving your projects a modern edge. What is the best laser for engraving metal? The fiber laser machine is a remarkable tool when it comes to laser marking on metal. With its high speed, no wear, and high accuracy, it produces clear and lasting marks on metal. Plus, with no additional external force or mechanical pressure, it is perfect for those jobs that require extra precision. But while the fiber laser engraving machine is a great tool for marking, you can't use it to cut metal - something to keep in mind! Excellent engraving effect Once marked by the fiber laser engraving machine, the marks left are not easy to erase. Under the high power energy, the target area of the object will vaporize rapidly or undergo chemical reaction, forming clear marks on the product surface. The marks on the metal surface are clear and beautiful. All kinds of logos, patterns, two-dimensional codes and characters can be directly and permanently engraved on metal products. High engraving accuracy The diameter of the focused fiber laser beam can be as small as 20um, which is very important for complex graphics and precise marking and engraving tasks. High engraving efficiency and simple operation The fiber laser engraver is simple to mark. The user only needs to set parameters on the computer and can directly mark or engrave in a few seconds. The desktop fiber laser engraver does not have a strong demand for cooling fan heat, does not need thermoelectric cooling and water cooling, only needs simple air cooling, and does not need to think about how to maintain. It is generally capable of working in a harsh environment and has a high tolerance to dust, vibration, impact, humidity and temperature. No damage to the surface The fiber laser marking engraving machine is a non-contact processing, and the laser head does not need to contact the surface of the object, so there is no need to consider the damage to the processed products. The processed surface is not only smooth and natural, but also will not damage the surrounding area. Since it is non-contact processing, it has no direct impact on the workpiece, will not cause mechanical deformation, and can adjust the energy and moving speed of the high-energy laser beam to achieve various processing purposes. Lower cost First, the fiber laser processing has no consumables and reduces the cost. Fiber laser engraver does not require consumables, and will not cause product deformation and disturbance. Therefore, there are few consumables. A basic 20W fiber laser can meet most of the needs, which saves power and is easy to integrate with the automation line to reduce costs. In addition, the fiber laser is stable and has a long service life. A basic 20W laser machine can meet most of the needs. Metal laser machine is widely used in many industries for its excellent performance. In terms of pricing, fiber laser engravers are more expensive than traditional processing equipment. But considering its nearly zero maintenance cost, it is now very popular in many fields. Find Your Metal Laser Engraver Machine The cheapest fiber laser machine can etch all kinds of metal and non-metallic materials, common metals such as iron, copper, magnesium and aluminum, and rare metals such as gold, silver, titanium and platinum. In addition, it can also carve various high hardness alloys, oxides, electroplating, electroplating, ABS, epoxy resin, printing ink, engineering plastics. It has a wide range of applications. What type of metal do you need to engraver? So you want to master laser engraving on metal? First, you need to know the best types of metal for laser engraving: Aluminum Aluminum is by far one of the most used metals in the laser industry because of its light weight and durability. It comes in various forms such as bare, anodized and cast. You will find that anodized alumina will whiten faster when marked with lower beam intensities. If it is bare or cast aluminum, it is better to use a darker mark, and a higher beam intensity will do the job. In any case, you must always make your marks as deep as possible and have the right contrast for aesthetic beauty. Therefore, the fiber laser is a fantastic aluminum engraving machine. Stainless steel After aluminum, stainless steel is the most commonly used, especially in areas with high hygiene requirements. Various projects that can be completed with stainless steel include kitchenware, tableware, accessories, etc. The metal supports all forms of marking, such as engraving, etching and even annealing. For this reason, it is very general and can be adapted to any markup parameter. Brass Brass is an alloy consisting mainly of copper and zinc. A wide range of properties can be obtained by percentage composition differences of major metals and the addition of other metals such as tin and lead. Brass is popular for its attractive golden color, low melting point, resistance to oxidation, and absence of iron. The 1.06 micron wavelength of the fiber laser is easily absorbed by brass, making it useful in both marking and cutting applications. Brass laser engraving creates a thicker black mark. Fiber lasers can cleanly cut complex patterns on thin brass sheets. Gold and silver The high precision of laser engraver is very suitable for the wear resistant permanent marking on the surface of precious and fine jewelry such as rings and necklaces. Since most jewelry is made of expensive raw materials such as gold, silver, platinum, and diamonds, the requirements for the production process are also very high. As an advanced processing equipment, laser marking machine has become the first choice for many jewelry processing manufacturers because of its unique advantages. Jewelry production is evolving, and traditional methods just can't keep up with modern demand. That's why laser marking machines are the perfect solution! Laser processing is super fast and efficient, and it won't cause any damage to the jewelry. Plus, you can input any text or designs you need directly into the software, and the laser will give you the perfect result in a matter of seconds. So whether you're looking for intricate patterns or something more simple, laser marking machines are the perfect way to get the job done! Frequently Asked Questions (FAQs) 1. What metals can be engraved using a fiber laser engraver?Fiber laser engravers are versatile and can mark a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, gold, silver, and platinum. They can also engrave coated or treated surfaces such as anodized aluminum or electroplated metals. 2. Can a fiber laser engraver cut metal as well as engrave it?Fiber lasers are primarily designed for marking and engraving. While they can cut thin metal sheets depending on the wattage, cutting is not their primary function. For metal cutting, a higher-powered fiber laser cutter would be more suitable. 3. Is fiber laser engraving permanent?Yes, the marks created by fiber laser engraving are permanent. The laser alters the material surface at a microscopic level, making it resistant to wear, fading, and corrosion. This makes it ideal for serial numbers, barcodes, and logos on metal products. 4. What maintenance is required for a fiber laser engraver?Fiber laser machines are known for their low maintenance. They do not require consumables like ink or chemicals, and cooling is typically done via air systems. Regular cleaning of lenses and ensuring the machine is dust-free are the main upkeep tasks. 5. Is fiber laser engraving safe for hobbyists and small businesses?Yes, fiber laser engravers are safe when used correctly. Desktop models are compact and come with safety enclosures or shielding. Always follow safety guidelines, wear protective eyewear if necessary, and ensure the workspace is well-ventilated.s Conclusion Compared to traditional marking, punching, printing, and engraving technologies, our laser engraving system offers numerous advantages. So, what are you waiting for? Get Monport laser engraver and make your projects faster and easier. Click here to shop your Monport laser engraver now and use code BESTMP10 at checkout to get started with the best tool in metal engraving. Don’t settle for less – upgrade to a fiber laser engraver and bring your projects to the next level!

The Ultimate Guide to Make Money With your Monport

If you've been struggling with your finances lately, it's time to make some changes. You can try to reduce your spending, but generally speaking, it's not people's first choice. On the contrary, they usually increase their income by looking for part-time jobs. Nowadays, there are many job opportunities, but laser engraving is by far one of the most popular jobs. First, there is no market you can't target. Second, it can be very profitable. If you are considering buying a laser machine and starting your own business, please continue to read this article, because we will tell you everything you need to know. Countless Opportunities The main advantage of starting a laser engraving business is that you can target many industries. For example, you can provide customers with customized jewelry. Yes, these are quite common, but remember, the demand is also very high. Nothing looks better than a pendant designed according to personal preferences. These lasers are very accurate, which means you can use them to create the most complex designs. In addition, remember that people will pay extra if you can make their vision come true. Next, large companies may hire you to engrave their products. You can work with some people in the automotive industry or leave a mark on medical products. For the latter, the inscriptions and numerical codes must be visible to the naked eye, which is why these companies have invested a lot of money in this aspect of the production process. We cannot emphasize the accuracy of laser engraving too much. It allows you to leave the smallest details on the surface. Finally, there are personalized gifts. We have mentioned jewelry, but the fact is that its market is very broad, and there are few restrictions because you can use this machine to leave traces on metal and non-metallic materials. Think of all the companies that can hire you with this service. In addition, each company will provide customers with promotional materials printed with their names or logos. How to earn money with a laser engraver? It's a very interesting way to make money with laser engraving machine. You can get extra income and even start your own business. You may be surprised that people want to engrave different things with lasers. From trophies to tombstones, there is a huge market for you to develop. Like all businesses, in order to succeed in the laser engraving business, you need to market your business correctly and provide excellent customer service and quality. Now that you have your own laser engraver, how can you make money with laser engraving machine? You have two main choices: Provide customers with laser engraving products Sell products For example, some popular laser engraving items are for your reference: #1 Customized coasters Laser cutting is not only suitable for practical products such as clocks and watches, but also for coasters that protect the surface from being scratched. It is also an ideal manufacturing technology that can create unique works of art that cannot be provided by any standard store. After seeing these laser cutting machine projects, you can't wait to make them. Custom coasters are a good gift for housewarming. Laser cutting acrylic acid is a good way to make coasters. Nothing is more intimate than custom design and laser cutting wooden gifts according to your specific specifications. We recommend amber bamboo or other light colored wood. #2 Plaque / sign If you laser engrave plaques and signs, you are likely to provide some services to commercial customers. If you consider how many logos are used by businesses around the world, you have a lot of business opportunities. If you provide enterprises with high-quality industry standard signs, you can obtain lucrative continuous contracts, which can improve your profits. #3 Jewelry Laser customized jewelry is a huge market. From earrings, necklaces, bracelets and rings, there are many great design concepts, so you will see all wooden jewelry, acrylic jewelry and so on. Laser cutting metal jewelry is the perfect way to make pendants, earrings, necklaces, brooches and almost all other wearable metals. In order to obtain a more beautiful choice, laser cutting and engraving are combined to add laser engraving design to any project formed by laser cutting. #4 Bookmark One of the main advantages of laser cutting products is to cut fine details accurately and consistently. The wooden bookmark seems to come from the complex fairy tale design. Most custom bookmarks on the market are made of wood or bamboo, but other materials can also be used. Bamboo, wood and even metal can use laser engraving machine to complete customized design. (it sounds like an opportunity for us!) In any case, after seeing these design concepts, it will attract customers to buy more bookmarks! #5 Wedding decorations Once your client or customer has set the date and found the location of the wedding and reception, you can start to enjoy the fun of wedding decoration. Whether the wedding or reception is in the church hall, hotel banquet hall, garden, park, backyard, the decoration chosen is to make this happy couple different. Laser cutting machine can make many different decorations, designed for a beautiful day, from the initial preservation date announcement to the wedding banquet, plus the reward items that the bride will like. #6 Keychains, badges, business cards When using laser creation, you will never be limited by design or materials, especially when using multi-functional materials. Laser cutting acrylic is the first choice of many manufacturers - acrylic is light, very durable, and can be easily cut by precision laser cutting technology. Design your own ultra-thin acrylic business cards with unique appearance and feel, make conference badges and ID cards that will not be damaged during washing, or design custom key chains in various colors. #7 Customized artworks Art can be a great addition to a home and offer many benefits to homeowners. While some people are still content to get mass-produced art from the store, many are drawn to the idea of getting custom art. This is great news for those who use laser cutters as they are able to create some absolutely stunning artwork. From small metal sculptures to large decorative boards displayed on the wall, they can be made by laser cutting machines. These unique items look good in any room of your home and are very considerate gifts for friends and family. There are no restrictions on the shapes, designs or patterns you can display in these works of art. Create cultural projects: Let students to create cultural designs and laser cut signs or flags for them; Create multidimensional topographic map; Lasers carve their hand-painted maps on wood or cardboard. Where can I sell my laser engraving items? There are many places where you can sell your laser engraving projects for money. The following ways are for your reference: Etsy Craft Exhibition(Fairs) Social media Your own website Local shops and businesses 1.How to Sell Your Laser Engraving Projects On Etsy Be Unique Make sure you spend some time on Etsy and look at the laser engraving projects that sell well. Try to create your own niche market so that you can really occupy the market. Take a good picture Make sure to present your project in the best way with beautiful and bright images in the Etsy list. Use good lighting and good background to show the best state of items. Be sure to show different angles. Check what others are doing so you can see what works (what doesn't). Tips for promoting Etsy store You want to know the search results of laser engraving products. To do this, you need to promote your Etsy store on websites such as pinterest and Facebook. Promotion and coupon codes are a way to put your product at the top of Etsy search results. 2.Create your own website If you plan to eventually become a full-time staff member, it is a good idea to set up your own website for your laser engraving business. You can direct potential customers to your website so that they can see the pictures of your works and know what you can offer them. On your website, you can display price lists and comments from satisfying customers. You can give the idea of the customization you provide, and you can also provide information about the customization work. Creating a website is not a big deal. You can start at $5-10 a month and promote your website on social media. Add links to Etsy stores to create more opportunities for product sales. 3.Selling laser engraving projects by social media Social media is free and everyone is using it now, so it makes sense to use it to sell your products. You can use Facebook or instagram to promote your Etsy store or website, or you can accept orders directly from Facebook or instagram. Facebook Facebook groups are a great place to promote your items. Find a group of moms, craftsmen and people looking for gift ideas. You should also create a Facebook page so that satisfying customers can leave comments and you can update your new items to your fans. Instagram Use Instagram to build fans and let people know about your business. You can even guide potential customers to your Instagram gallery. 4.Craft Exhibition The handicraft fair is a good place to sell laser engraving works. Church and community Christmas fairs are another great place, and you'll have a lot of potential buyers. Book a stall at a flea market or craft fair and sell your goods. Be sure to make business cards so that you can accept custom orders. 5.Local shops Another place to sell laser engraving projects is to ask if your local store will show you these works, or if they will ask you to post flyers to promote your business. Can I succeed? Oh, yes, of course. We've discussed the different things you can create, but remember that this is only a small part of your choice. Obviously, you may need some time to start making big money, but when it comes to work in this industry, many people can prove how profitable it is. Like any other type of business, there are many things you must consider and plan. Start by studying machines and understand their characteristics so that you can make informed decisions when buying machines and all other equipment. Then, continue to study the market in your region to understand how you should use this technology and how to make money. Finally, invest some time and energy in advertising your new company to attract customers. Purchasing a Monport laser engraving machine can realize most of your engraving projects, achieve the most functions with the highest cost performance, and greatly improve the success probability of your project. For any questions about laser engraving, please consult our service team. FAQs What materials can Monport laser machines process?Monport laser systems can handle a wide range of materials, including wood, acrylic, metal, leather, and glass, making them perfect for versatile engraving and cutting projects. What are the key advantages of Monport CO₂ laser engravers?Monport CO₂ lasers deliver outstanding precision, spacious work areas, and strong cutting power—ideal for makers, crafters, and small businesses. Why should I consider a Monport fiber laser?Monport fiber lasers are designed for exceptional speed and precision, making them the go-to choice for metal engraving and industrial-grade applications. Are Monport machines suitable for beginners?Absolutely. Many Monport models arrive fully or partially assembled and feature user-friendly controls and step-by-step tutorials for a smooth setup experience. What sets Monport apart from other brands?Monport stands out with its competitive pricing, robust construction, and excellent software compatibility—making it a smart choice for both beginners and professional. Unlock Big Savings at Monport Laser! Use code BESTMP10 at checkout for an exclusive discount – Click here to shop now!