Introduction

There are many different ways to make a laser mark. You can use the old-fashioned method of burning the image into the material with a plasma beam, or you can use a pulsed laser with a solid-state gain medium. But if you're looking for something that's more efficient, more accurate, and offers more flexibility than either of those two options, then you may want to consider fiber laser machines.

Engraving machine for sale options are widely available, allowing you to find a variety of fiber laser machines that suit different needs and budgets.

Fiber laser marking and cutting are two of the most popular applications for fiber lasers. Both processes can be used to mark or cut a wide range of materials, but there are some key differences between them. In this blog post, we’ll discuss the benefits of fiber laser marking over fiber laser cutting, as well as the differences between them.

What is fiber laser marking?

Fiber laser marking is a process that uses a single high-powered beam of light to etch or mark materials. The beam breaks down the material at the molecular level, allowing it to be easily removed from the surface being marked. Manufacturers who want to make their products stand out with unique markings or logos often used this process.

This allows you to create detailed designs and logos without having to use stencils or masks as you would need with other methods such as laser etching or engraving. Engraving machine for sale can help with these kinds of intricate designs.

What is fiber laser cutting?

Fiber laser cutting is also known as direct write machining (DWM). It involves using intense bursts of light from a high-power tube or rod to heat up certain areas on a workpiece until they melt away completely or get cut through completely. This process is often used by manufacturers who want to create intricate designs in metal materials like aluminum or stainless steel without having to use expensive equipment like mills and lathes.

Fiber laser cutting works by using infrared beams emitted from a single source that is then focused down into an area where they converge into one spot before hitting your material (usually metal). As soon as they hit this convergence point, they heat up so much that they burn through anything they touch—including steel! The result is a clean cut without any burrs left behind as you'd get from plasma cutters or grinders; however, because these lasers work so quickly and efficiently, their cost tends to be higher than other options available.

Why choose fiber laser marking machines?

The main advantage of using fiber lasers for marking applications is that they can be adjusted to produce high-quality markings on a wide variety of materials including plastics and metals such as stainless steel or aluminum without damaging or distorting them during marking processes. Engraving machine for sale offers flexibility to suit these requirements.

Fiber laser marking machines are also cost-effective compared to traditional methods of marking such as engraving or etching. Engraving machine for sale often comes with competitive pricing, making them a great investment for businesses.

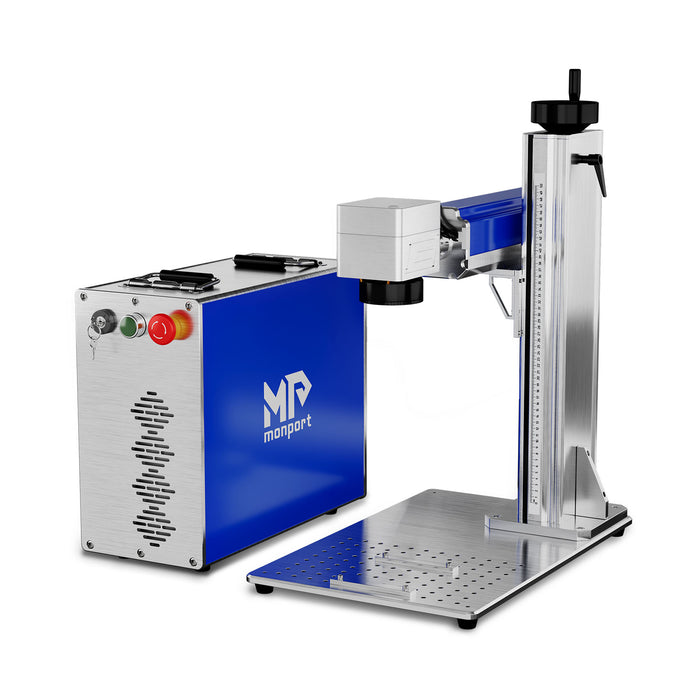

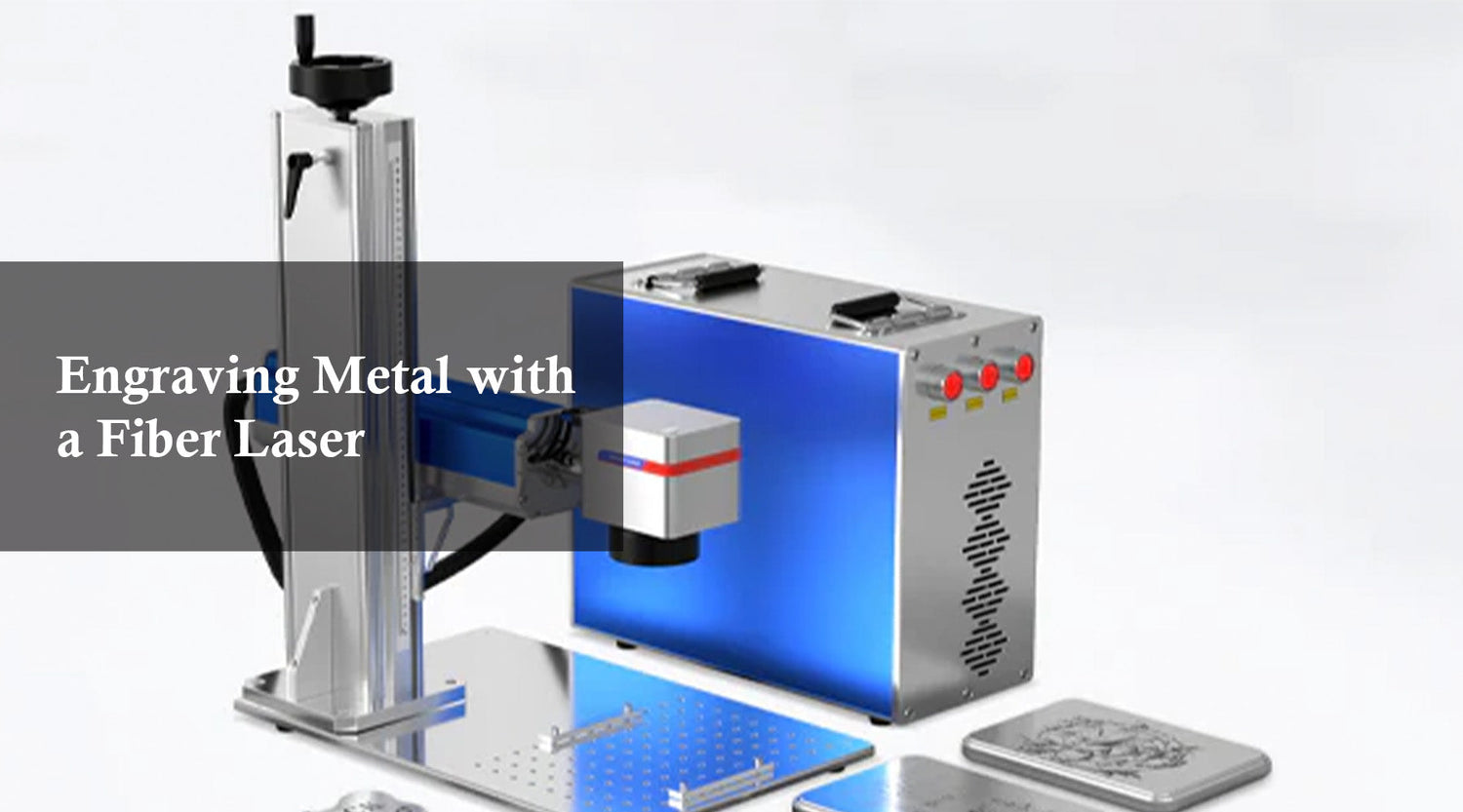

Monport Fiber Laser Marking Machine

If you're looking for the best laser marking machines, then you've come to the right place. Here at Monport, we offer a wide range of high-quality fiber lasers that are perfect for all of your laser marking needs. Whether you're looking for a 20W laser or a 50W laser, we have something that will fit your budget and will provide years of reliable service.Engraving machine for sale through Monport offers the best in quality and service, making sure your investment is worthwhile.

If you need to mark or engrave your products with a high-quality finish, Monport's fiber laser marking system is the right choice for you. Our 20W/30W/50W fiber laser marking engraver can be used for a variety of applications and materials, from plastic to metal to glass and more.

For example, if you're looking for a way to mark the surface of your metal products with a highly durable finish that will last, our monochromatic 20W/30W/50W fiber laser marking machine is perfect for this task. It's designed with the user in mind—the software is easy to use, even if you're new to this kind of technology! The machine itself is even easier to use: simply load up your product on the platform, press start, and watch as it moves along its path while burning in your design.

Our 50W fiber laser engraver has an additional feature that makes it unique compared to other models: it can engrave both sides of a material at once! This allows you to cut costs by doubling production speed and efficiency. Engraving machine for sale with this feature can help businesses grow faster.

If you're looking for something smaller and more portable than our 20W/30W models but still want the same quality results at an affordable price point.

You can use Monport laser machines to create everything from simple logos for personal use up to more complex designs used in jewelry production. We offer great prices and a wide selection of sizes so you can find the perfect fit for your needs.

Conclusion

To summarize, A fiber laser marking machine has many unique features that make them ideal for smaller marking tasks. It only takes a little bit of time to learn their features and how to use them to get the job done. With the right technology, anyone can get a terrific result from their next marking task, no matter how small that job may be. Consider investing in an engraving machine for sale to take your projects to the next level.