When considering high-performance laser engraving, the integrated fiber laser and the split fiber laser are two paths to exceptional results. What's the difference between these two machines: split and integrated fiber laser systems? This question arises frequently among professionals and hobbyists looking to enhance their engraving capabilities. In this article, we delve into the advantages of both, focusing on Monport’s cutting-edge laser solutions and why investing in these machines can transform your projects.

|

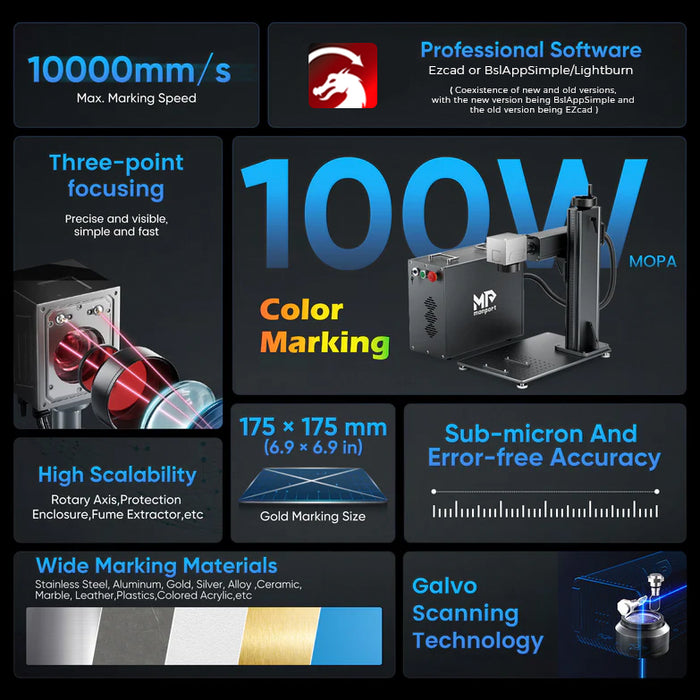

Monport GA 100W Upgraded Integrated MOPA Fiber Laser Engraver & Marking Machine with Auto Focus |

Monport GPro 100W Split MOPA Fiber Laser Engraver & Marking Machine With Manual Focus |

|

|

|

Why Choose Monport for Fiber Laser Engraving?

Monport stands out in the laser engraving industry due to its relentless pursuit of innovation and quality. Their machines, such as the Monport GA 100W Integrated MOPA Fiber Laser and the Monport GPro 100W Split MOPA Fiber Laser, cater to diverse engraving needs, providing superior performance, durability, and user-friendly features. Monport lasers are known for precision, reliability, and long service life, making them a worthwhile investment for businesses and creators alike.

Advantages of Monport Laser Machines

- Advanced Technology: Monport lasers come equipped with features like auto-focus, adjustable pulse width, and extensive frequency ranges.

- Ease of Use: Monport’s machines are designed for quick setup and easy operation, making them accessible to beginners and professionals.

- Durability: With an expected service life of 100,000 hours, Monport lasers are built to withstand long-term use.

- Precision and Speed: Marking speeds of up to 15,000mm/s ensure efficiency without compromising accuracy.

What's the Difference Between These Two Machines: Split and Integrated Fiber Laser?

Understanding the fundamental differences between the integrated fiber laser and the split fiber laser is key to selecting the right tool for your needs. Let’s break down the differences using Monport’s top models.

Monport GA 100W Integrated MOPA Fiber Laser – Auto Focus

The Monport GA 100W Integrated MOPA Fiber Laser is designed for high precision and ease of use. Here are its standout features:

- Laser Power: 100W

- Working Area: 6.9" x 6.9"

- Wavelength: 1064nm

- Machine Dimension: 50cm x 37.5cm x 65cm

- Marking Speed: Up to 10,000mm/s

- Auto-Focus Technology: Streamlines the engraving process with error margins below ±1mm.

- Compact Design: The all-in-one design combines the laser source and engraving head into a single, sleek unit.

Benefits of Monport GA 100W

- Plug-and-Play Setup: Installation takes just one minute, making it one of the easiest machines to get started with.

- High Precision: Achieve intricate designs with minimal effort.

- Enhanced Efficiency: The auto-focus system reduces errors and increases productivity.

- Robust Build: The aluminum body enhances durability and stability.

Monport GPro 100W Split MOPA Fiber Laser – Manual Focus

The Monport GPro 100W Split MOPA Fiber Laser offers greater flexibility and scalability for larger projects. Key features include:

- Laser Power: 100W

- Working Area: 6.9" x 6.9"

- Wavelength: 1060-1080nm

- Machine Dimension: 35cm x 55cm x 69.5cm

- Marking Speed: Up to 15,000mm/s

- Manual Focus: Allows precise control over focus adjustments.

- Split Design: The laser source is separate from the engraving head, enabling better heat dissipation and scalability.

Benefits of Monport GPro 100W

- Higher Marking Speed: Faster engraving speeds compared to integrated models.

- Versatility: Suitable for a wide range of materials and applications.

- Enhanced Stability: Features high-end galvanometers for greater accuracy and reduced interference.

- Security and Control: Includes safety features like access keys and emergency stop buttons.

Key Differences Between Integrated and Split Fiber Lasers

| Feature | Integrated Fiber Laser | Split Fiber Laser |

|---|---|---|

| Design and Portability | Compact, all-in-one unit | Larger footprint, separate laser source and engraving head |

| Focus Mechanism | Auto-focus for quick adjustments | Manual focus for precise control |

| Application and Use Case | Ideal for small projects and rapid production | Suitable for industrial settings and complex tasks |

| Marking Speed | Up to 10,000mm/s | Up to 15,000mm/s |

| Heat Management | Limited heat dissipation | Better heat dissipation and scalability |

Engraving Ideas and Applications for Monport Fiber Lasers

Both the integrated and split fiber lasers from Monport can engrave on various materials, including stainless steel, anodized aluminum, and plastics. Common applications include:

- Personalized Jewelry

- Industrial Marking

- Customized Electronics

- Artistic Creations

- Promotional Products

Key Takeaways

- Integrated fiber lasers are compact, user-friendly, and ideal for quick, precise engraving.

- Split fiber lasers offer greater flexibility, speed, and scalability for industrial applications.

- Monport’s GA 100W Integrated and GPro 100W Split Fiber Laser engravers cater to different needs, ensuring there’s a perfect solution for every engraving project.

Q&A About Monport Laser Machines

Q: What’s the difference between these two machines: split and integrated fiber laser? A: Split fiber lasers have separate laser sources and engraving heads, providing greater flexibility and heat dissipation. Integrated fiber lasers combine all components into a single unit for compactness and ease of use.

Q: Which Monport laser is best for beginners? A: The Monport GA 100W Integrated MOPA Fiber Laser is ideal for beginners due to its auto-focus feature and easy installation.

Q: Can Monport fiber lasers engrave on metal? A: Yes, both the GA 100W and GPro 100W models can engrave stainless steel, anodized aluminum, and more.

Conclusion

Choosing between the integrated fiber laser and the split fiber laser depends on your specific needs and project scope. By understanding what's the difference between these two machines: split and integrated fiber laser, you can make an informed decision that maximizes efficiency and precision in your engraving work. Monport continues to lead the market with innovative and reliable laser engraving solutions. Whether you prioritize compact design and ease of use or seek enhanced flexibility and scalability, Monport has the right machine to meet your needs. Embrace the future of engraving with Monport, where quality and performance converge to elevate your creative potential.