Introduction

Leather crafting has always been an art form admired for its durability, versatility, and elegance. With the advent of CO2 laser technology, the possibilities for customizing and personalizing leather have expanded significantly. One of the most exciting applications of CO2 lasers is in the creation of detailed and intricate laser leather patches. This blog post will explore how CO2 lasers can be used to engrave black leather sheets, transforming them into unique and personalized leather patches that can be used for various applications.

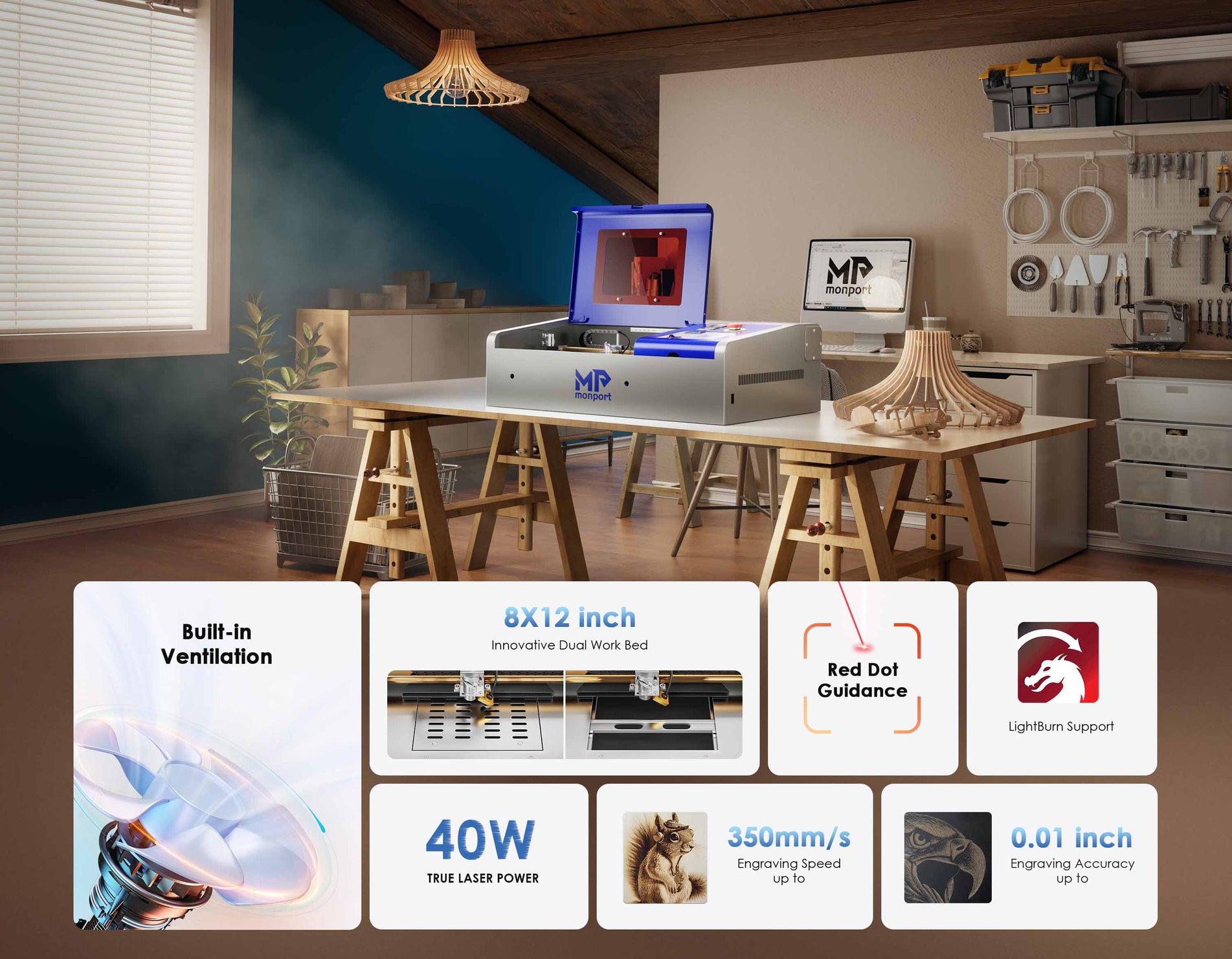

Understanding CO2 Laser Technology

CO2 lasers are a type of gas laser that uses carbon dioxide as the laser medium. These lasers are renowned for their ability to cut, engrave, and mark a wide range of materials, including leather. The laser emits a high-intensity beam of light that is focused onto the material, creating precise and clean cuts or engravings. The advantages of using CO2 lasers for leather crafting include high precision, speed, and the ability to reproduce intricate designs consistently.

Why Choose CO2 Lasers for Leather Crafting?

Precision and Detail: CO2 lasers provide exceptional precision, allowing for the creation of intricate patterns and designs on black leather sheets. This level of detail is difficult to achieve with traditional methods like hand carving or stamping.

Customization: With CO2 lasers, you can easily customize leather patches with logos, text, or artwork. This makes it an ideal choice for creating personalized items, from branded patches to custom gifts.

Clean Cuts: The laser's focused beam ensures clean and accurate cuts without fraying or damaging the edges of the leather. This is particularly important when working with delicate or detailed designs.

Speed: CO2 lasers can process leather quickly, making it possible to produce multiple patches in a short amount of time. This efficiency is beneficial for both small-scale projects and large production runs.

Preparing Black Leather Sheets for Laser Engraving

Before you start engraving, it's essential to prepare your black leather sheets properly:

Choose the Right Leather: Ensure that the leather you use is suitable for laser engraving. Full-grain leather or vegetable-tanned leather are often preferred for their ability to hold detailed engravings well.

Clean the Leather: Dust and debris on the leather can affect the quality of the engraving. Gently clean the surface with a soft cloth to remove any particles.

Test a Sample: It’s always a good idea to test your design on a small piece of leather before proceeding with the final project. This helps you adjust settings and ensure the desired outcome.

Designing Laser Leather Patches

Designing your laser leather patches involves several steps:

Create or Import a Design: Use graphic design software to create or import your design. Ensure the design is compatible with the laser cutter’s software and is sized appropriately for your leather patches.

Adjust Laser Settings: Depending on the thickness and type of leather, you may need to adjust the laser settings, including power, speed, and frequency. Refer to the laser cutter’s manual or guidelines for leather-specific settings.

Position the Leather: Place the black leather sheet on the laser cutter’s bed, ensuring it is properly aligned and secured. Accurate positioning is crucial for achieving a consistent engraving.

Engraving Process

Once your setup is complete, you can begin the engraving process:

Start the Laser Cutter: Initiate the engraving process according to the laser cutter’s instructions. The laser will follow the design, engraving the black leather sheet with precision.

Monitor the Process: Keep an eye on the engraving to ensure everything is proceeding smoothly. Make adjustments if necessary to address any issues that may arise.

Inspect the Results: After the engraving is complete, carefully inspect the laser leather patches. Check for any imperfections or areas that may need touch-ups.

Finishing and Using Laser Leather Patches

After engraving, you may need to perform some finishing touches:

Clean the Patches: Gently clean the engraved patches to remove any residue or debris left from the laser process.

Condition the Leather: Applying a leather conditioner can help maintain the leather’s suppleness and prevent it from drying out.

Attach or Use: Depending on your project, you can attach the patches to various items such as jackets, bags, or accessories. Ensure they are securely fastened and aligned properly.

Applications and Ideas

Laser leather patches can be used in various applications, including:

- Custom Apparel: Personalize jackets, hats, or bags with unique patches.

- Branding: Create branded patches for companies or organizations.

- Gifts: Design custom patches for special occasions or personalized gifts.

- Home Decor: Incorporate leather patches into home decor items for a stylish touch.

Conclusion

Using CO2 lasers to engrave black leather sheets offers a fantastic opportunity to create personalized and professional-quality leather patches. The precision, speed, and versatility of CO2 lasers make them an invaluable tool for leather crafters and businesses alike. Whether you’re looking to add a personal touch to your leather goods or create customized items for sale, laser leather patches are a creative and impactful choice. Embrace the power of CO2 laser technology and explore the endless possibilities it offers in leather crafting.