Introduction

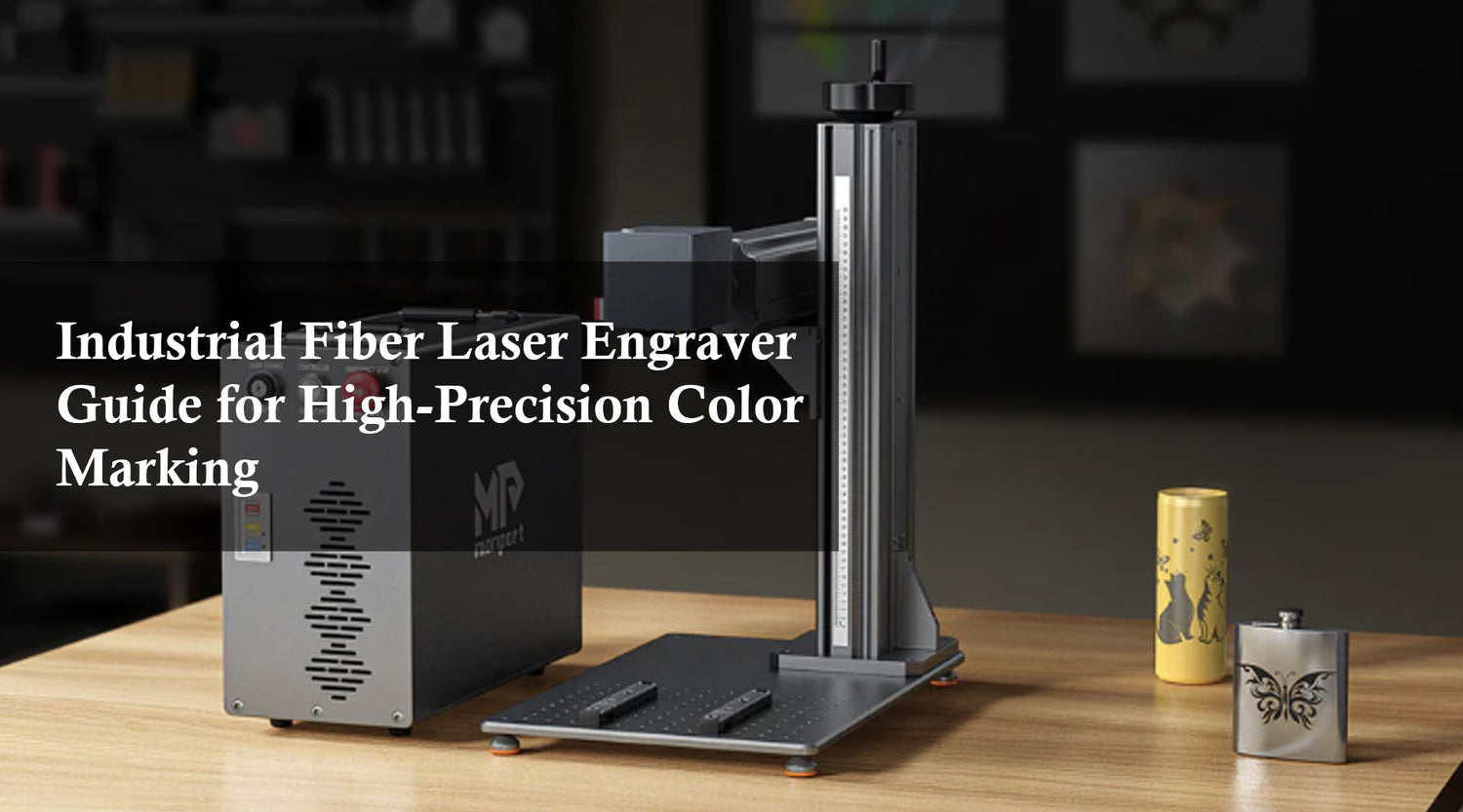

Are you looking for a powerful and precise way to personalize or mass-produce engraved materials? Whether you're a small business owner, a DIY enthusiast, or a large-scale manufacturer, investing in the right desktop laser engraver or industrial laser cutter can make a huge difference in quality and efficiency.

In this guide, we'll explore different desktop laser engraver and industrial laser cutter options, the types of materials they can process, and how you can benefit from using CO2 laser engravers for your projects. If you're ready to take your engraving game to the next level, check out these options:

-

Desktop CO2 Laser Engraver and Cutter

-

Industrial CO2 Laser Engraver

Desktop CO2 Laser Engraver and Cutter

Industrial CO2 Laser Engraver

What is Laser Engraving and Cutting?

Laser engraving and cutting use a high-powered laser beam to etch or cut into materials with precision. Depending on your needs, you can choose between a desktop laser engraver for small projects or an industrial laser cutter for heavy-duty applications.

Types of Laser Engraving Machines

There are two primary types of laser engravers based on their power and application:

-

Desktop CO2 Laser Engraver – Ideal for small businesses, hobbyists, and personal projects.

-

Industrial CO2 Laser Cutter – Designed for large-scale production and high-volume engraving needs.

Best Materials for Laser Engraving and Cutting

Commonly Used Materials

| Material | Desktop CO2 Laser Engraver | Industrial CO2 Laser Cutter |

|---|---|---|

| Wood | Yes | Yes |

| Acrylic | Yes | Yes |

| Leather | Yes | Yes |

| Glass | Yes | Yes |

| Metal (coated) | Yes | Yes |

| Fabric | Yes | Yes |

| Paper/Cardboard | Yes | Yes |

| Stone | No | Yes |

| Stainless Steel | No | Yes (with marking spray) |

Both desktop laser engraver and industrial laser cutter models offer great flexibility depending on the material and the intricacy of your designs.

Benefits of Using a CO2 Laser Engraver

1. High Precision and Detail

A desktop laser engraver or industrial laser cutter can produce incredibly fine details, making it perfect for intricate designs and personalized products.

2. Speed and Efficiency

Using a CO2 laser engraver, you can quickly engrave or cut through materials, reducing production time and increasing output.

3. Versatility

From desktop laser engravers for small businesses to industrial laser cutters for mass production, there’s a solution for every need.

4. Low Maintenance and Cost-Effective

A CO2 laser engraver has minimal moving parts, which means lower maintenance costs and longer durability.

How to Choose the Right Laser Engraver

For Small Businesses and Hobbyists:

-

Choose a desktop laser engraver if you work with small to medium-sized materials.

-

Look for ease of use and compatibility with your design software.

-

Check power output—40W to 60W is ideal for most personal projects.

For Industrial Use:

-

Invest in an industrial laser cutter for higher production volumes.

-

Choose a model with at least 100W power for thicker materials.

-

Look for features like air assist, autofocus, and high-speed engraving capabilities.

Frequently Asked Questions (FAQs)

1. What is the difference between a desktop and an industrial laser cutter?

A desktop laser engraver is designed for smaller projects, while an industrial laser cutter has more power, larger working areas, and is meant for high-volume production.

2. Can a CO2 laser engraver cut metal?

A CO2 laser engraver cannot cut metal directly but can mark coated metals. An industrial laser cutter with the right power and attachments can engrave metal.

3. How much maintenance does a laser engraver require?

Regular cleaning of lenses and mirrors, checking alignment, and ensuring proper ventilation can help maintain the performance of your CO2 laser engraver.

Important Details to Consider

-

Power Output – Determines the type of materials you can engrave or cut.

-

Work Area Size – Choose a machine that fits your project needs.

-

Software Compatibility – Ensure it works with design software like CorelDRAW or Adobe Illustrator.

-

Cooling System – CO2 lasers require water cooling to prevent overheating.

Key Takeaways

-

A desktop laser engraver is best for small businesses and personal projects.

-

An industrial laser cutter is ideal for mass production and high-volume cutting.

-

CO2 laser engravers provide precision, speed, and versatility.

-

Consider power, material compatibility, and work area size before purchasing.

Conclusion

Investing in the right desktop laser engraver or industrial laser cutter can take your engraving business to new heights. Whether you're creating custom gifts, signage, or industrial parts, a CO2 laser engraver provides the precision and efficiency needed for high-quality results.

Check out our top laser engravers and cutters today:

-

Desktop CO2 Laser Engraver and Cutter

-

Industrial CO2 Laser Engraver

Upgrade your engraving business today with the best in laser technology!