Using the Monport acrylic laser cutter and understanding the best settings for laser cutting acrylic are crucial steps for achieving smooth, sharp, and professional-looking results. Whether you’re crafting signs, ornaments, display panels, or prototypes, having the right tool and technique makes all the difference. For creators and professionals who demand performance and precision, Monport delivers a laser cutting solution that’s both powerful and user-friendly. In this guide, we’ll explore how to make the most out of your Monport acrylic laser cutter, reveal the best settings for laser cutting acrylic, and introduce complementary tools like Monport’s black laser marking spray for those looking to expand their capabilities.

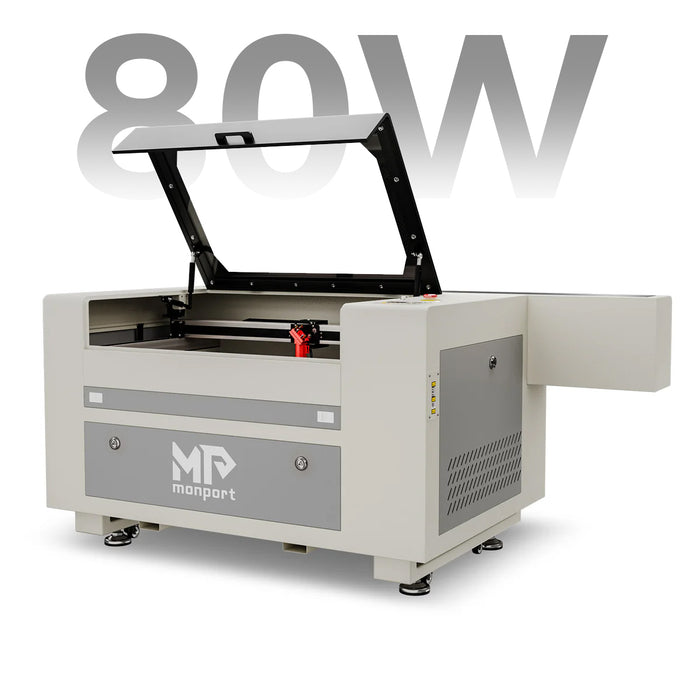

Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus

Why Choose the Monport Acrylic Laser Cutter?

The Monport acrylic laser cutter stands out in a saturated market due to its advanced features, intuitive software compatibility, and industry-grade durability. Specifically, the Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus is a game-changer for users aiming for both precision and versatility. It features a large 16"x24" working area and pass-through slots that accommodate oversized materials with ease. With speeds reaching 800mm/s, and a depth capacity of 8.6", this machine is engineered for serious productivity. Whether you’re working on small detailed cuts or larger commercial signage, the best settings for laser cutting acrylic paired with Monport’s high-performance hardware give you control and consistency every time.

Best Settings for Laser Cutting Acrylic with the Monport 80W CO2 Laser

Finding the best settings for laser cutting acrylic depends on the thickness of the material and the desired finish. With Monport’s intuitive control panel powered by the Ruisin KT332N motherboard, adjusting power, speed, and frequency is seamless. For example:

-

For 3mm acrylic: Speed 300mm/s, Power 30–40%

-

For 6mm acrylic: Speed 150mm/s, Power 50–60%

-

For 10mm acrylic: Speed 80mm/s, Power 70–85%

These settings are perfect starting points, and Monport’s responsive Z-axis movement ensures optimal focus adjustments for perfect cuts. The 4-in-1 laser head — combining emission, autofocus, air assist, and red light indication — reduces errors and saves time, giving you polished edges without burns or residue.

Monport Advantages for Acrylic Projects

Spacious Work Area and High-Speed Cutting

The Monport acrylic laser cutter is built for professionals who need efficiency and size. Its 24" x 16" work area and four-way pass-through make it suitable for banners, layered signage, and larger acrylic sheets. With a max acceleration of 8000 mm/s² on the X-axis, the cutter maintains speed without sacrificing precision. This matters when working with intricate patterns or mass production, making it easy to meet deadlines while maintaining high standards.

Compatibility and Control

The Monport 80W supports RDWorks and LightBurn, and works with both Windows and Mac, ensuring maximum compatibility. Combined with a real-time trajectory display and power-off resume function, users can work confidently without fear of losing progress or misalignment. Adjusting layer parameters on the fly helps dial in the best settings for laser cutting acrylic, making each job more efficient.

Built for Longevity and Reliability

Developed in partnership with Yongli, the Monport laser tube boasts over 12,000 hours of usage — 6.5% more power than competitor machines with similar specs. The high-quality metal honeycomb and aluminum panels offer double protection and durability. Its industrial-grade build quality ensures your investment lasts and performs reliably with every cut.

Safety and Efficiency Combined

With built-in emergency stop, laser lock key, cover detection, and ventilation systems, the Monport acrylic laser cutter offers unparalleled safety for both hobbyists and professionals. The fireproof window allows monitoring without halting your workflow, and the machine auto-stops in cases of overheating or low water, ensuring your safety without compromising output.

Creative Acrylic Engraving Ideas with Monport

The precision of the Monport acrylic laser cutter opens up endless possibilities:

-

Custom LED edge-lit signs with etched designs

-

Business logos on colored acrylic panels

-

Holiday ornaments and personalized gifts

-

Layered acrylic art combining transparent and opaque materials

-

Storefront displays with frosted text effects

Pairing these creative ideas with the best settings for laser cutting acrylic allows artists and businesses to consistently deliver clean, attractive pieces with minimal waste or post-processing.

Unlock New Possibilities with Monport Black Laser Marking Spray

Beyond acrylic, many creators and professionals also need to mark metal surfaces. Enter Monport’s black laser marking spray — a must-have accessory for CO2 laser users working on metal. Perfect for serializing tools, personalizing jewelry, or customizing metal tumblers, this spray produces high-contrast, permanent black marks on stainless steel, aluminum, brass, and more.

Designed for use with CO2 lasers 25W and above, this spray transforms any compatible surface into a canvas for your next laser design. Its advanced nanoparticle formula and anti-clog nozzle ensure even application and superior coverage. Simply clean the surface, shake the can for 2 minutes, and spray from a 6–8 inch distance. Within five minutes, the coating is dry and ready for engraving. After lasering, rinse and reveal the bold black mark with no sticky residue.

With the Monport acrylic laser cutter, you can easily switch from acrylic cutting to metal marking by adding this spray to your toolkit. For users seeking versatility and efficiency, black laser marking spray is a game-changer.

Key Takeaways

-

The Monport acrylic laser cutter offers premium features such as a large work bed, auto-focus, 4-in-1 laser head, and industry-grade safety systems.

-

Finding the best settings for laser cutting acrylic ensures cleaner cuts, better edge quality, and faster processing.

-

The Monport 80W CO2 Laser Engraver & Cutter is ideal for acrylic due to its 800mm/s speed, 8.6” depth, and advanced control panel.

-

Complement your setup with black laser marking spray, allowing permanent marking on various metals using your CO2 laser.

-

Creative options are limitless — from signage to gifts to art — all with Monport’s reliable performance and cutting-edge technology.

Frequently Asked Questions About Monport

Q: What materials can the Monport 80W laser cutter work with?

A: The Monport 80W CO2 laser cutter can handle acrylic, wood, glass, leather, rubber, paper, and even coated metals (with the help of black laser marking spray).

Q: How does autofocus help when cutting acrylic?

A: Autofocus ensures the laser is always at the correct distance from the material’s surface, which is crucial for precision and smooth edges. It reduces the need for manual calibration and improves cut consistency.

Q: Can I use LightBurn with the Monport 80W?

A: Yes! The machine is compatible with both RDWorks and LightBurn, offering full functionality on both Windows and macOS platforms.

Q: Is black laser marking spray necessary for engraving metal?

A: Yes. Standard CO2 lasers do not mark bare metal surfaces effectively. Black laser marking spray enables high-contrast, durable markings on metals, making it essential for metal customization.

Q: How durable are the marks created using black laser marking spray?

A: The marks are permanent, heat-resistant, and scratch-proof. They're ideal for industrial, decorative, or commercial applications.

Conclusion

When it comes to cutting acrylic with finesse and professional precision, the Monport acrylic laser cutter is the top choice for creators of all levels. Its smart features, speed, and spacious design make it easy to find and dial in the best settings for laser cutting acrylic, giving you perfect cuts every time. And if you want to expand your horizons beyond acrylic, Monport’s black laser marking spray allows you to mark metal effortlessly, unlocking even more creative potential.

Whether you’re crafting one-of-a-kind art, building a product line, or customizing gifts, Monport gives you the tools to excel. From acrylic sheets to metal surfaces, your journey to clean, precise, and versatile laser work begins here.