In the world of precision engraving and cutting, having the right tools can make all the difference. Whether you're a hobbyist or a professional, understanding how to use an industrial laser cutting machine and a glass etching tool effectively is essential. This article will guide you through the process of using these advanced tools, with a particular focus on the Monport 80W Industrial Laser Engraver.

Introduction to Industrial Laser Cutting

For anyone involved in detailed craftsmanship, an industrial laser cutting machine and a glass etching tool are invaluable assets. These tools enable precise and intricate designs on various materials, making them ideal for both creative projects and industrial applications. This guide will walk you through the steps of using the Monport 80W Industrial Laser Engraver, ensuring you get the most out of your equipment.

Setting Up the Monport 80W Industrial Laser Engraver

Special Offer | Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus

1. Unpacking and Assembling

When you first receive your Monport 80W Industrial Laser Engraver, follow these steps:

- Unpack the Machine: Carefully unpack all components and check for any damage during shipping.

- Assemble the Components: Follow the user manual to assemble the machine, ensuring all parts are securely attached.

- Connect the Power Supply: Plug in the power supply to a stable electrical outlet.

2. Installing the Software

- Download the Software: Visit the Monport website to download the necessary software for your industrial laser cutting machine.

- Install the Software: Follow the installation instructions provided by Monport.

- Connect the Machine to Your Computer: Use the provided USB cable or Wi-Fi connection to link your machine to your computer.

3. Calibrating the Laser

- Check the Laser Alignment: Ensure that the laser is properly aligned according to the manual.

- Adjust the Focal Length: Set the correct focal length for your specific project. This is crucial for achieving precise cuts and engravings.

Using the Glass Etching Tool

1. Preparing the Glass

- Clean the Glass Surface: Ensure the glass is free from dust and grease.

- Masking the Glass: Apply masking tape or a stencil to protect areas that should not be etched.

2. Setting Up the Design

- Create or Import a Design: Use the Monport software to create a new design or import an existing one.

- Adjust the Settings: Set the power, speed, and frequency according to the type of glass and the desired depth of etching.

3. Etching the Glass

- Place the Glass on the Workbed: Secure the glass piece firmly to prevent any movement during the etching process.

- Start the Etching Process: Begin the etching process and monitor the progress to ensure accuracy.

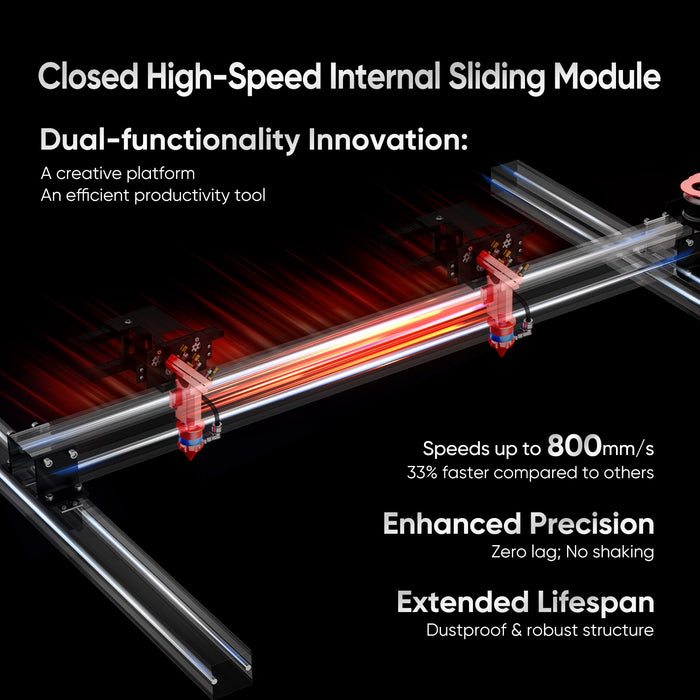

Advanced Features of the Monport 80W Industrial Laser Engraver

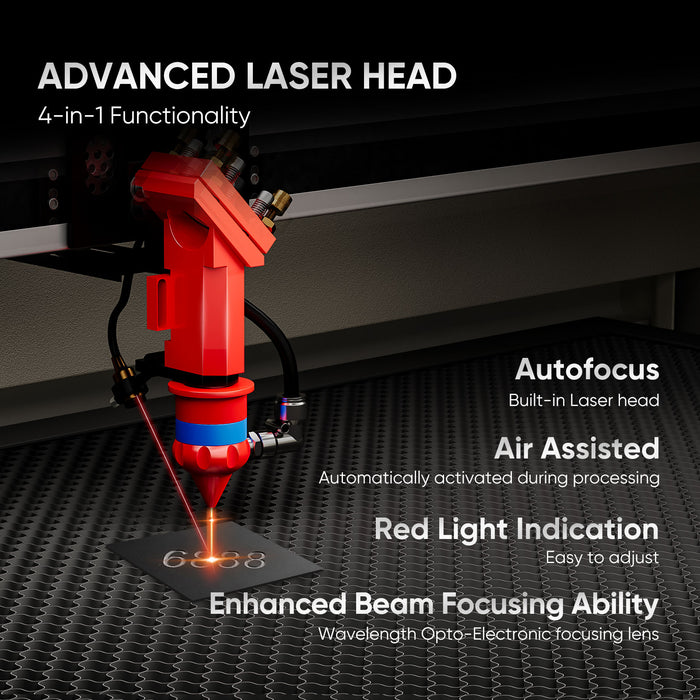

1. Auto-Focus System

The Monport 80W Industrial Laser Engraver comes with an auto-focus system that automatically adjusts the laser's focal length, ensuring precision and ease of use.

2. High-Resolution Engraving

With a high-resolution engraving capability, this industrial laser cutting machine can produce intricate and detailed designs, making it perfect for both artistic and industrial applications.

3. Versatile Material Compatibility

The Monport 80W is not limited to glass; it can also engrave and cut wood, acrylic, leather, and more, providing versatility for various projects.

Key Takeaways

- The industrial laser cutting machine and glass etching tool are essential for precision engraving and cutting.

- Proper setup and calibration of the Monport 80W Industrial Laser Engraver are crucial for optimal performance.

- Advanced features such as auto-focus and high-resolution engraving enhance the functionality of the Monport 80W.

- Regular maintenance and proper handling of materials are key to achieving high-quality results.

Q&A About Monport Laser Engravers

What materials can the Monport 80W Industrial Laser Engraver work with?

The Monport 80W can engrave and cut a variety of materials including glass, wood, acrylic, leather, and more.

How do I ensure the safety of the machine during operation?

Always follow the manufacturer's safety guidelines, ensure proper ventilation, and wear appropriate protective gear such as safety glasses.

Can the Monport 80W engrave on curved surfaces?

Yes, with the appropriate rotary attachment, the Monport 80W can engrave on curved surfaces such as glass bottles and cylindrical objects.

How often should I clean and maintain the machine?

Regular maintenance should be performed after each use, with thorough cleaning and inspection at least once a month to ensure optimal performance.

Where can I find support and resources for using the Monport 80W?

Support and resources, including user manuals and troubleshooting guides, can be found on the Monport website.

Conclusion

Using an industrial laser cutting machine and a glass etching tool can significantly enhance your ability to create precise and intricate designs. The Monport 80W Industrial Laser Engraver offers a range of advanced features that make it an excellent choice for both hobbyists and professionals. By following the setup and usage guidelines outlined in this article, you can achieve high-quality results with your laser engraving projects. For more information and support, visit Monportlaser.com.

Read More: In-Depth Guide to Industrial Water Chillers and Industrial Air Purifiers